Acclimation method for processing molasses alcohol wastewater sludge

A technology for molasses alcohol wastewater and sludge, applied in chemical instruments and methods, natural water treatment, anaerobic digestion treatment, etc., to achieve stable system operation, solve seasonal stagnation, and improve removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

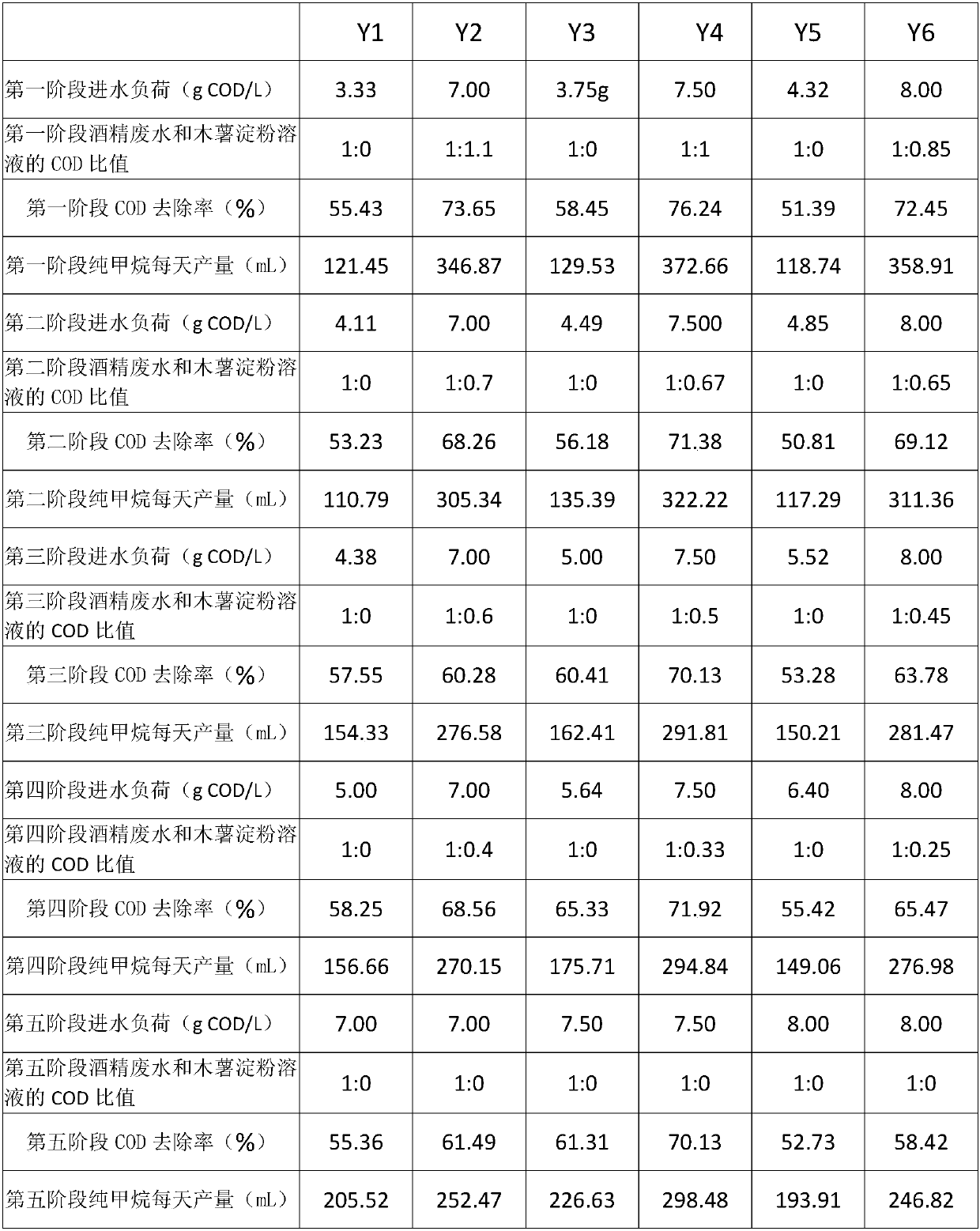

Embodiment 1

[0024] Step 1. Use self-made fermentation bottle combined with AMPTS-II automatic methane potential system for anaerobic fermentation.

[0025] Step 2. According to the ratio of COD of molasses alcohol wastewater to COD of cassava starch solution of 1:1.1, configure the water inlet, so that the total COD is 7.0g COD / L.

[0026] Measure 100mL of activated sludge, put it into a fermentation bottle, add the mixed wastewater composed of the molasses alcohol wastewater and tapioca starch solution to make the final volume of the reactor 400mL, and put it into a mechanical stirring system. Nitrogen was passed into each reaction flask to ensure an anaerobic environment, and the seal of the fermenter was checked at the same time.

[0027] Step 3. React continuously for three days and observe the gas production. If the gas production and gas production rate of several groups are basically the same, it indicates that the parallel state of the reaction system and the operation are in good...

Embodiment 2

[0030] Step 1. Use self-made fermentation bottle combined with AMPTS-II automatic methane potential system for anaerobic fermentation.

[0031] Step 2. According to the COD ratio of the molasses alcohol wastewater and the COD of the cassava starch solution is 1:1, the influent is configured so that the total COD is 7.5g COD / L.

[0032] Measure 150mL of activated sludge, put it into a fermentation bottle, add the mixed wastewater composed of the molasses alcohol wastewater and tapioca starch solution to make the final volume of the reactor 400mL, and put it into a mechanical stirring system. Nitrogen was passed into each reaction flask to ensure an anaerobic environment, and the seal of the fermenter was checked at the same time.

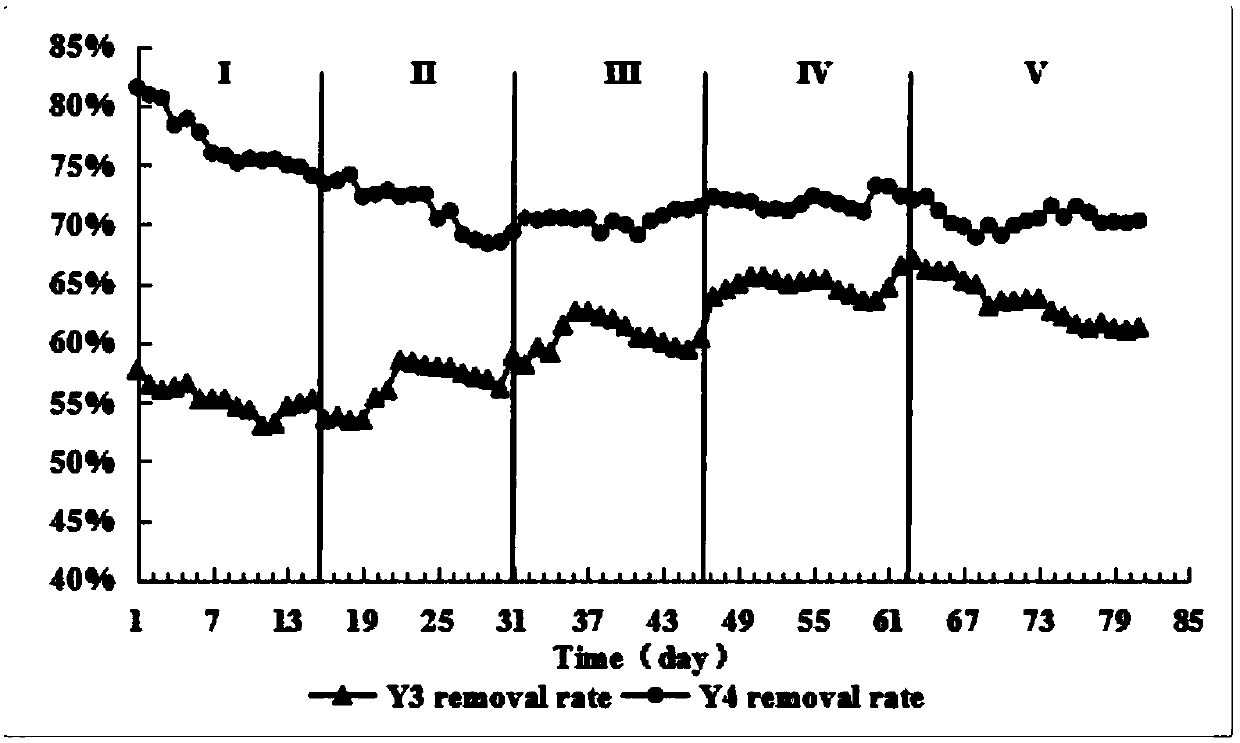

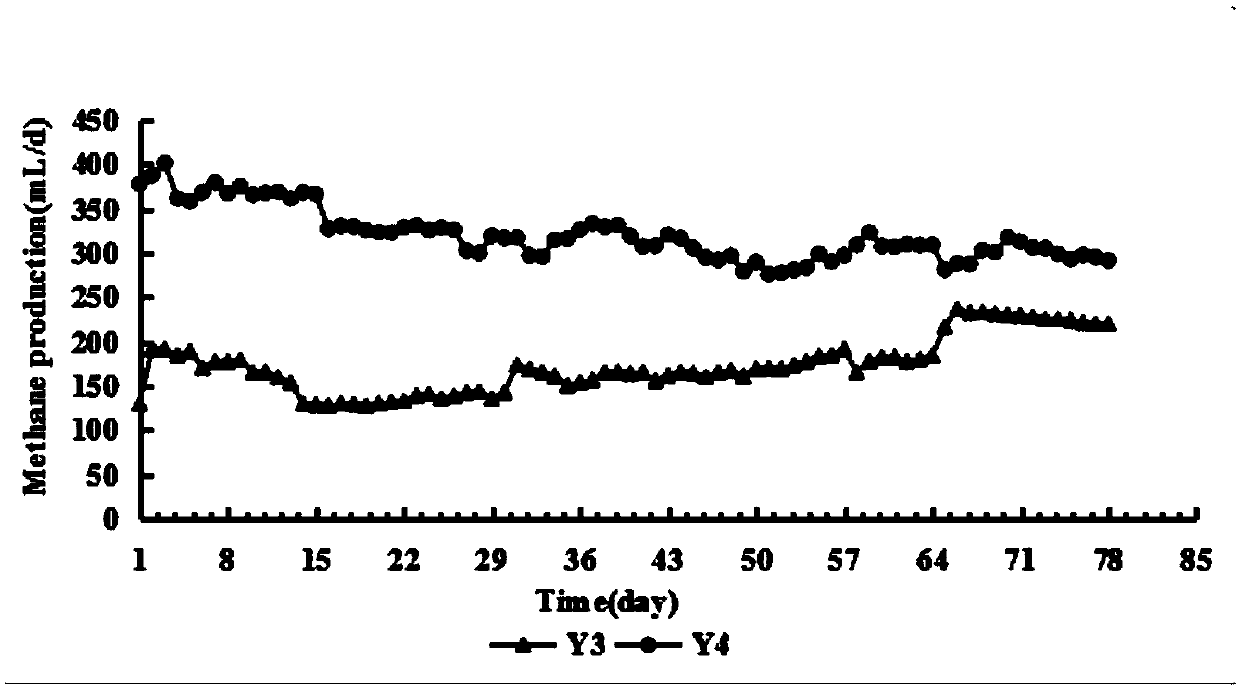

[0033] Step 3. React continuously for three days and observe the gas production. If the gas production and gas production rate of several groups are basically the same, it indicates that the parallel state of the reaction system and the operation are...

Embodiment 3

[0036] Step 1. Use self-made fermentation bottle combined with AMPTS-II automatic methane potential system for anaerobic fermentation.

[0037] Step 2. According to the ratio of COD of molasses alcohol wastewater to COD of cassava starch solution of 1:0.85, configure the water inlet so that the total COD is 8.0g COD / L.

[0038] Measure 170mL of activated sludge, put it into a fermentation bottle, add the mixed wastewater composed of the molasses alcohol wastewater and tapioca starch solution to make the final volume of the reactor 400mL, and put it into a mechanical stirring system. Nitrogen was passed into each reaction flask to ensure an anaerobic environment, and the seal of the fermenter was checked at the same time.

[0039] Step 3. React continuously for three days and observe the gas production. If the gas production and gas production rate of several groups are basically the same, it indicates that the parallel state of the reaction system and the operation are in good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com