Method for preparing porous oxide film resistant to weak acid corrosion

A porous oxide and thin film technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of pore size, distribution and area limitation, template method Expensive preparation cost, easy to damage the porous structure of the film, etc., to achieve the effect of mature preparation equipment, wide application range and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a porous oxide film resistant to weak acid corrosion, comprising the following steps:

[0030] S1), the preparation of precursor solution, the titanium acetate of 0.2g, and the zinc chloride (ZnCl) of 0.04g 2 ), 0.2g of polyethylene glycol (PEG), and 30mL of ethylene glycol were mixed, and stirred at 80°C for 60min using a magnetic stirrer to make titanium acetate, ZnCl 2 and polyethylene glycol are completely dissolved in ethylene glycol to obtain a precursor solution;

[0031] S2), the preparation of the precursor film, put the cleaned substrate on the spin coater and absorb it, use a dropper to drop 6 drops of the precursor solution on the substrate, start the spin coater, first at 400 rpm Rotate at a speed of 120s, then rotate at a medium speed of 1200 rpm for 60s, and then rotate at a high speed of 3000 rpm for 120s; then use a hot plate to dry at 150°C and then spin-coat again, and spin-coat repeatedly 20 times. Thereby obtaining the prec...

Embodiment 2

[0035] A preparation method of a porous oxide film resistant to weak acid corrosion, comprising the following steps:

[0036] S1), the preparation of precursor solution, the tin acetate of 0.4g, and the zinc chloride (ZnCl) of 0.08g 2 ), 0.2g of polyethylene glycol (PEG, molecular weight 2000-6000), and 30mL of ethylene glycol were mixed, and stirred at 80°C for 60min using a magnetic stirrer to make tin acetate, ZnCl 2 and polyethylene glycol are completely dissolved in ethylene glycol to obtain a precursor solution;

[0037] S2), the preparation of the precursor film, put the cleaned substrate on the spin coater and absorb it, use a dropper to drop 6 drops of the precursor solution on the substrate, start the spin coater, first at 500 rpm Rotate at a high speed for 60s, then rotate at a medium speed of 1300 rpm for 60s, and then rotate at a high speed of 3500 rpm for 120s; then use a hot plate to dry at 150°C and then spin-coat again, and repeat the spin-coating 25 times. ...

Embodiment 3

[0041] Performance Analysis of Porous Oxide Thin Film Resistant to Weak Acid Corrosion

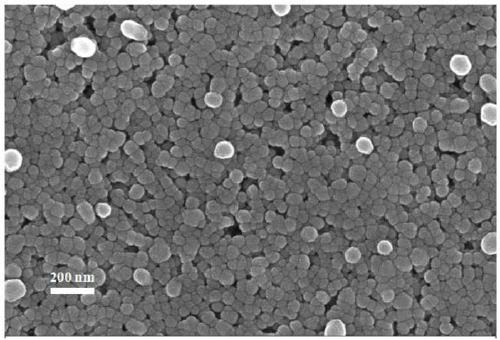

[0042] figure 1 It is the porous TiO after high temperature sintering prepared in Example 1 2 High-magnification SEM picture of the film; it can be clearly observed from the picture that there are some holes on the surface of the film, and some raised ZnO nanocolumns are distributed with a diameter of 70-120nm.

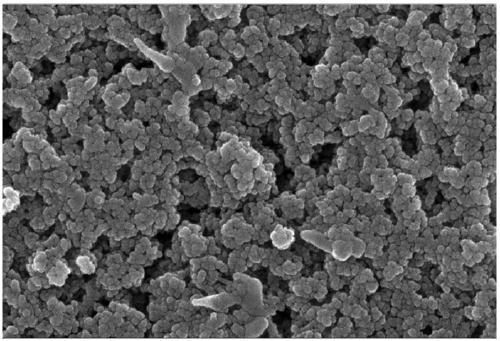

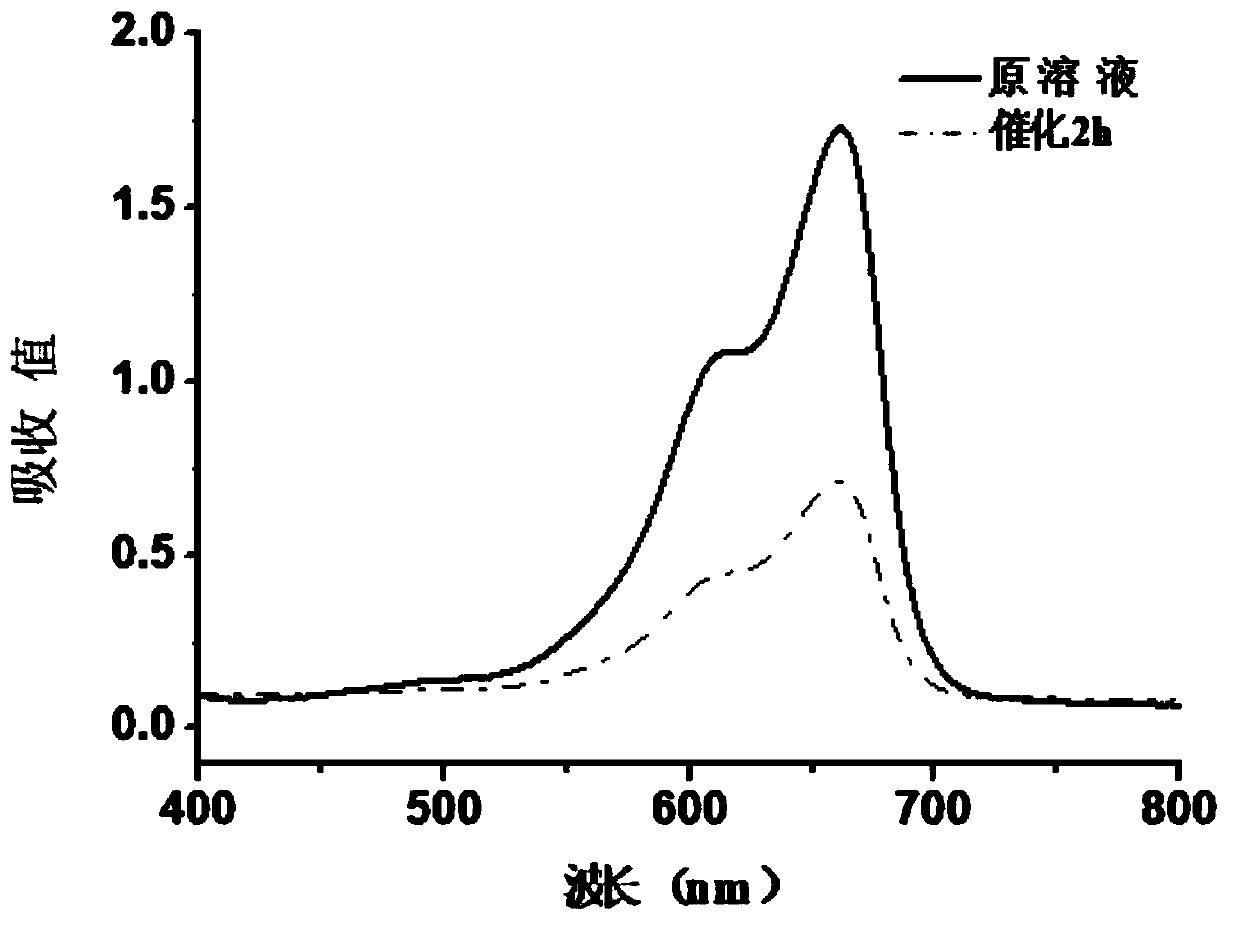

[0043] figure 2 It is the weak acid corrosion resistant porous TiO prepared in Example 1 of the present invention 2 High-magnification SEM image of the film, after etching, the pores of the film increase significantly; image 3 It is the weak acid corrosion resistant porous TiO prepared in Example 1 2 Absorption spectrum of photocatalytic degradation of methylene blue by thin film, after weak acid corrosion resistant porous TiO 2 After 2 hours of catalytic degradation of the film, the absorption value of methylene blue decreased rapidly from 1.70 to 0.69, which proves that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com