Preparation method of vegetable protein/gum arabic/lipid emulsified edible composite film

A technology of gum arabic and plant protein, which is applied in the food field, can solve the problems of unstable double-layer film, easy to fall off, unsatisfactory water vapor barrier performance, etc., achieve excellent hydrophobic properties, simple process, improve mechanical strength and other properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of soybean protein / gum arabic / lipid emulsified edible composite film comprises the following steps:

[0047] (1) Preparation of soy protein isolate-gum arabic (SPI-GA) cross-linked product

[0048] Gum arabic powder and soybean protein isolate were mixed with a minimum amount of deionized water at a ratio of 1:1, and poured into a plate for freeze-drying. Grind the obtained freeze-dried powder raw material into fine powder, spread it into a plate and place it in a desiccator (about 79% relative humidity) with saturated potassium bromide on the bottom layer, and place the desiccator in an oven with a temperature setting of 60°C Carry out proteoglycan glycosylation and cross-linking, and take it out after 48 hours for later use.

[0049] (2) Preparation of SPI-GA oil film film-forming solution

[0050] Film-forming solutions with different components were configured according to Table 1. Weigh the cross-linked product according to the recipe and di...

Embodiment 2

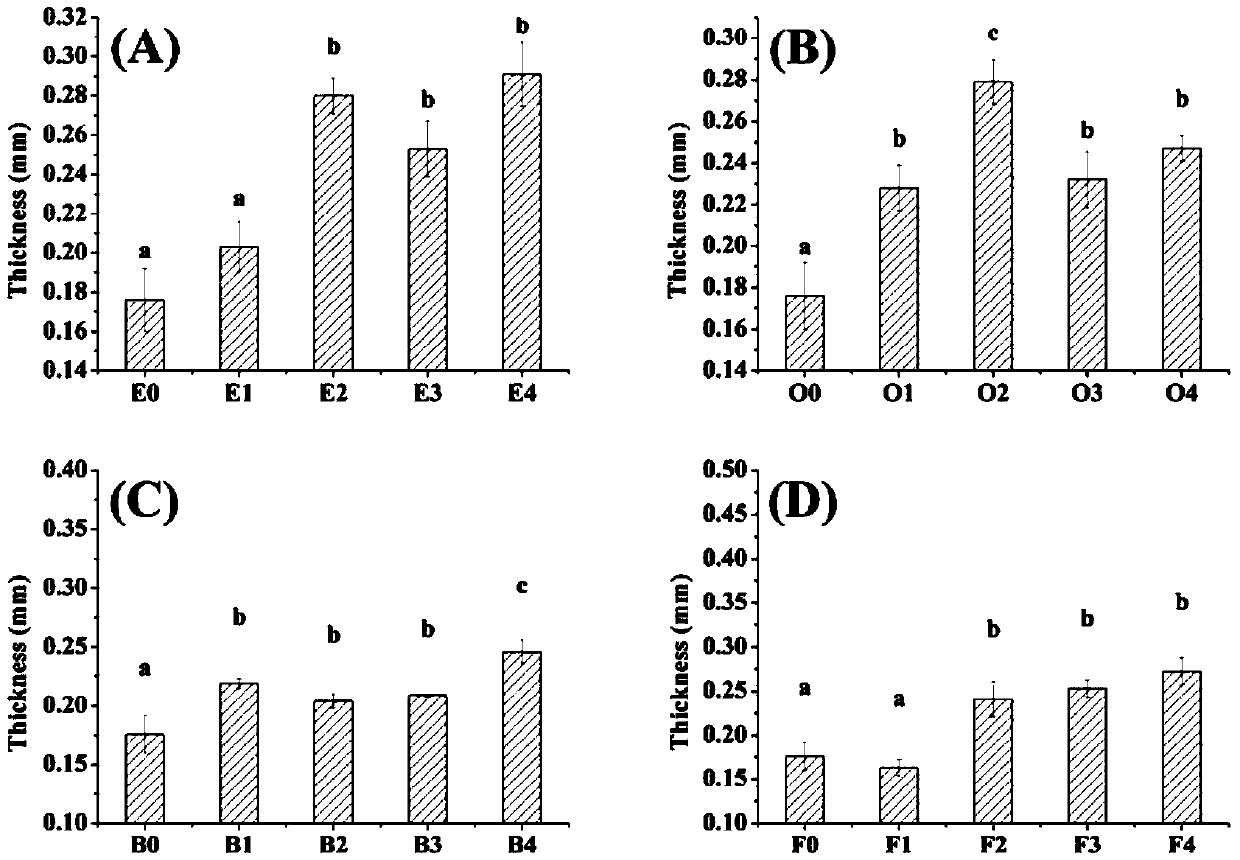

[0058] The influence of embodiment 2 different kinds of oils and fats on edible film thickness

[0059] Edible film thickness The film thickness is measured with an electronic digital display micrometer, accurate to 0.001. Three measurements were randomly drawn for each film sample. The resulting average value was used to calculate the transparency of the film.

[0060] The result is as figure 1 As shown, the addition of oil can significantly affect the thickness of the film compared to the film without adding oil. This is because the addition of oil can increase the solid content in the film-forming solution, thereby increasing the thickness of the film. In addition, the type of grease significantly affects the thickness of the film. Compared with the four oils, the essential oil film is the thickest, while the beeswax film is the thinnest. This may be related to the molecular weight of the oil itself, that is, at the same concentration, the smaller the molecular weight,...

Embodiment 3

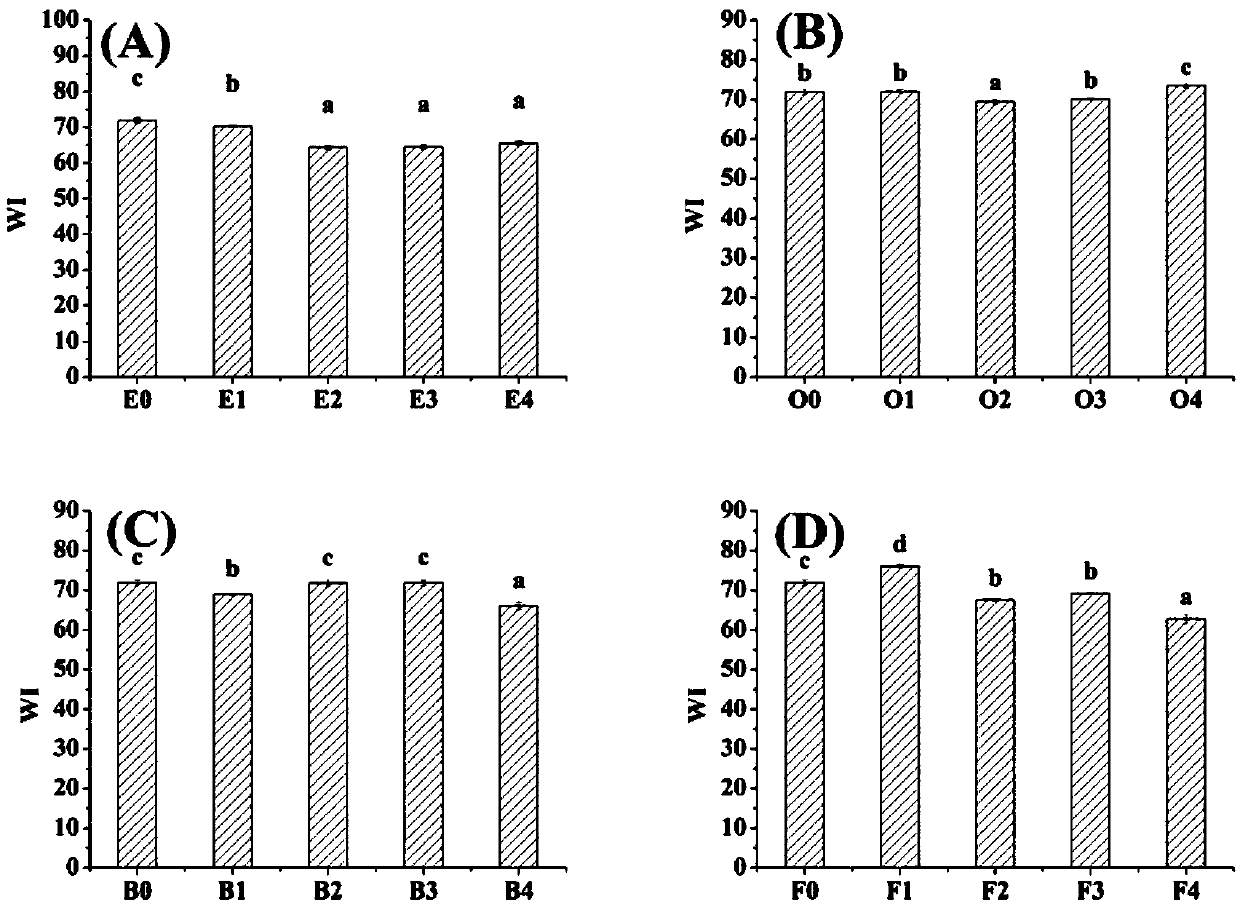

[0061] The influence of embodiment 3 different kinds of oils and fats on the whiteness index of edible film

[0062] Edible film chromaticity: use a precision colorimeter to measure the chromaticity value of the film. Each film sample was placed on a uniform white background plate, and three measured values were randomly selected [6]. The whiteness index (WI) value is defined as:

[0063]

[0064] where the L* (black 0 to white 100), a (red 120 to green -120) and b* (yellow 120 to blue -120) values correspond to whiteness, red and yellow, respectively.

[0065] The result is as figure 2 As shown, when oil is added, the WI value of the film is generally smaller than that of the blank control, which may be due to the color of the oil itself. In addition, the addition of oil has specific effects on the structure of the membrane, for example, changing the compactness of the membrane, which is also the reason for the change of the WI value of the membrane [12].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com