Fungus residue biological reaction material, reactors and application of reactors

A bioreactor and bioreaction technology, which is applied in the direction of fertilizers made from biological waste, application, and bio-organic part treatment, can solve the problems of waste of bacteria residue resources, the inability to apply large-scale applications, and the lack of nutrients in straw, etc., to achieve a solution Effects of nutritional deficiencies, promotion of accumulation, and high content of mycelium protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

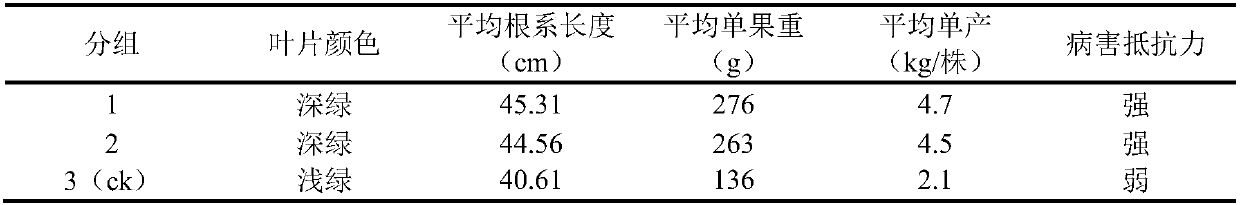

Examples

Embodiment 1

[0033] 1. Collection of wood rot fungus (shiitake mushroom, oyster mushroom, seafood mushroom, enoki mushroom, etc.)

[0034] (1) Collect non-polluting, non-mildew waste wood rot fungus sticks;

[0035] (2) Bacteria sticks are removed from the bag. The edible fungus sticks of wood rot fungi are packed in polyethylene plastic bags, and the sticks are manually removed from the bag before use;

[0036] (3) After the bag is removed, the wood rot fungus stick is pulverized with a pulverizer, and the wood rot fungus residue is obtained after pulverization.

[0037] 2. Grass rot fungi (Agaricus bisporus, Straw mushroom, Brown mushroom, etc.)

[0038] Grass rot fungus cultivation requires a lot of straw and chicken, cattle, and sheep manure. Grass rot fungi are cultivated in mushroom beds. The mushroom beds are hot-dip galvanized bed frames. Grass rot fungus fermentation culture materials are placed on the bed frames. The fermentation culture materials are composed of straw, It is c...

Embodiment 2

[0040] 1. Obtained decomposing bacteria agent

[0041] Mix 10 parts by mass of decomposed bacteria, 150 parts by mass of wheat bran, 5 parts by mass of brown sugar, and 200 parts by mass of water, and stack and ferment for 6 hours. The decomposed bacteria agent obtained after ~30°C. The original species of microbial decomposing strains used were purchased from Ningxia Fengyuan Biotechnology Co., Ltd.

[0042] 2. Preparation of fungal residue bioreaction material

[0043] Mix 1000 parts by mass of fungus residue and 1 part by mass of decomposed fungal agent evenly to obtain a bioreaction material 1 for fungal residue; wherein, the fungus residue consists of 1 part by mass of wood rot fungus residue and 3 parts by mass of grass rot fungus residue.

Embodiment 3

[0045] 1. Obtained decomposing bacteria agent

[0046] Mix 15 parts by mass of decomposed bacteria, 200 parts by mass of wheat bran, 8 parts by mass of brown sugar, and 250 parts by mass of water, and stack and ferment for 6 hours. The decomposed bacteria agent obtained after ~30°C. The original species of microbial decomposing strains used were purchased from Ningxia Fengyuan Biotechnology Co., Ltd.

[0047] 2. Preparation of fungal residue bioreaction material

[0048] Mix 1200 parts by mass of fungus residue and 3 parts by mass of decomposed microbial agent evenly to obtain bioreaction material 2 for fungus residue; wherein, the fungus residue consists of 3 parts by mass of wood rot fungus residue and 5 parts by mass of grass rot fungus residue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com