A kind of preparation method of hollow fiber micro/ultrafiltration membrane

An ultrafiltration membrane and fiber technology, which is applied in the field of preparation of hollow fiber micro/ultrafiltration membranes, can solve the problems of high resistance, low membrane porosity, and low permeation flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

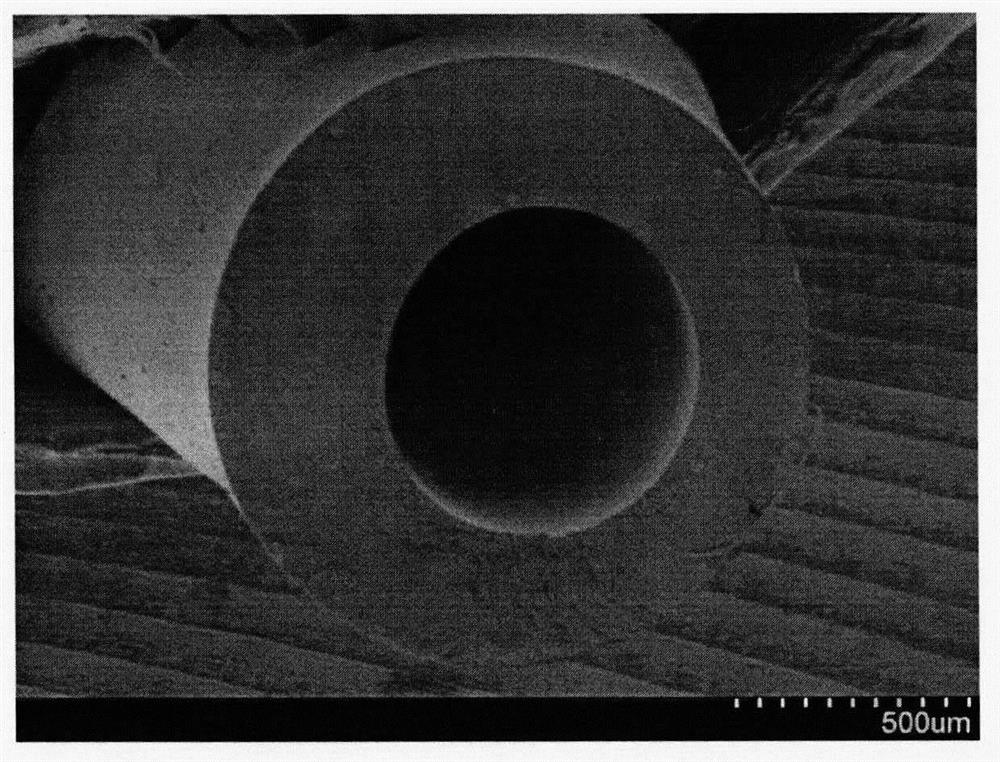

Image

Examples

Embodiment 1

[0030] According to the high molecule PVDF mass content of 12%, the mass content of the second polymer polyvinylpyrrolidone (PVP) is 12%, the solvent DMAC mass content is 68%, and the molecular pore agent is magnesium chloride. The percentage content was 8% to configure a PVDF cast film, first dissolved in DMAC, first added PVDF and PVP, stirred at 40 ° C constant temperature dissolution to form a completely uniform PVDF cast film solution, and stand stouled. Thereafter, the above-mentioned preformed PVDF cast film solution extruded into the spinning hollow fiber in the spinneret of the two-channel structure at 40 ° C, the inner layer channel is a core liquid passage, and the outer layer channel is a cast film solution. The channel, the core is 90 ° C, the flow rate of the cast film solution and the core and the spinning speed, and in the air segment, it is immersed in an outer gel bath of 90 ° C after 1 second, and the primary ecosystem is separated, from fluid The film is solidi...

Embodiment 2

[0033] According to the high molecule PVDF mass content of 16%, the mass content of the second polymer polyvinylpyrrolidone (PVP) is 4%, the solvent DMAC mass content is 72%, and the mass of magnesium chloride in small molecule The percentage content was 8% to configure the PVDF cast film solution, first dissolved in magnesium chloride in DMAC, and then PVDF and PVP were added, stirred at a constant temperature dissolved in 45 ° C to form a completely uniform PVDF cast film solution, and stand stamped. Thereafter, the above-mentioned PVDF cast film fluid extruded out of the spun hollow fiber in the spinneret of 45 ° C, the inner layer channel as a core channel, and the outer layer channel is a cast film solution. The passage, the core liquid is 45 ° C, the flow rate of the cast film solution and the core, and the spinning speed, directly immersed in an outer gel bath water, and the primary ecosystem is separated, and the film is solidified from the liquid phase, and then The film ...

Embodiment 3

[0036] According to the high molecule PVDF mass content of 12%, the mass content of the second polymer polyvinylpyrrolidone (PVP) is 4%, and the content of solvent DMAC is 73%, and the mass of magnesium chloride of small molecules. The percentage content is 11% to configure the PVDF cast film solution, first dissolve the magnesium chloride in DMAC, then add PVDF and PVP, stirring heating at a constant temperature dissolution of 35 ° C to form a completely uniform PVDF cast film solution, and stand stamp. Thereafter, the prepared PVDF cast film liquid extruded out of the spun hollow fiber in the spinneret of the three-channel structure at 35 ° C, the inner layer channel is a core liquid passage, and the core is 93 ° C. The intermediate layer channel is a cast film liquid passage. The outermost channel is a gel dielectric passage, a water of the gel medium, controls the flow rate of the cast film solution, the outermost gel medium, and the spinning velocity, After 5 seconds of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com