Copper-doped ZnO-ZrO2 sosoloid catalyst and preparing method and application thereof

A catalyst and solid solution technology, which is applied in the field of catalysts for hydrogenation of carbon dioxide to methanol and their preparation, can solve the problems of low carbon dioxide conversion rate and poor methanol selectivity, and achieve the effects of excellent catalyst performance, high methanol selectivity and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

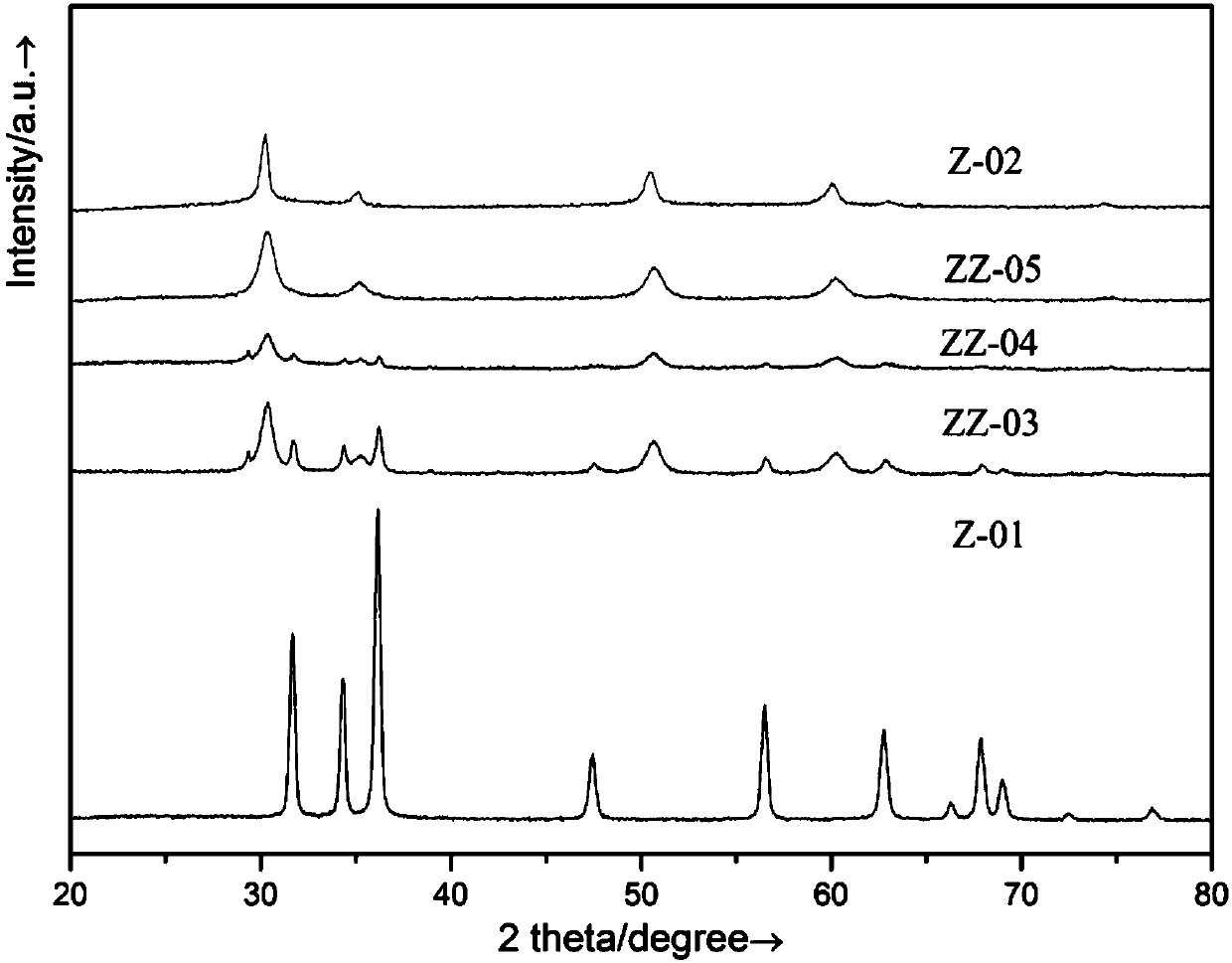

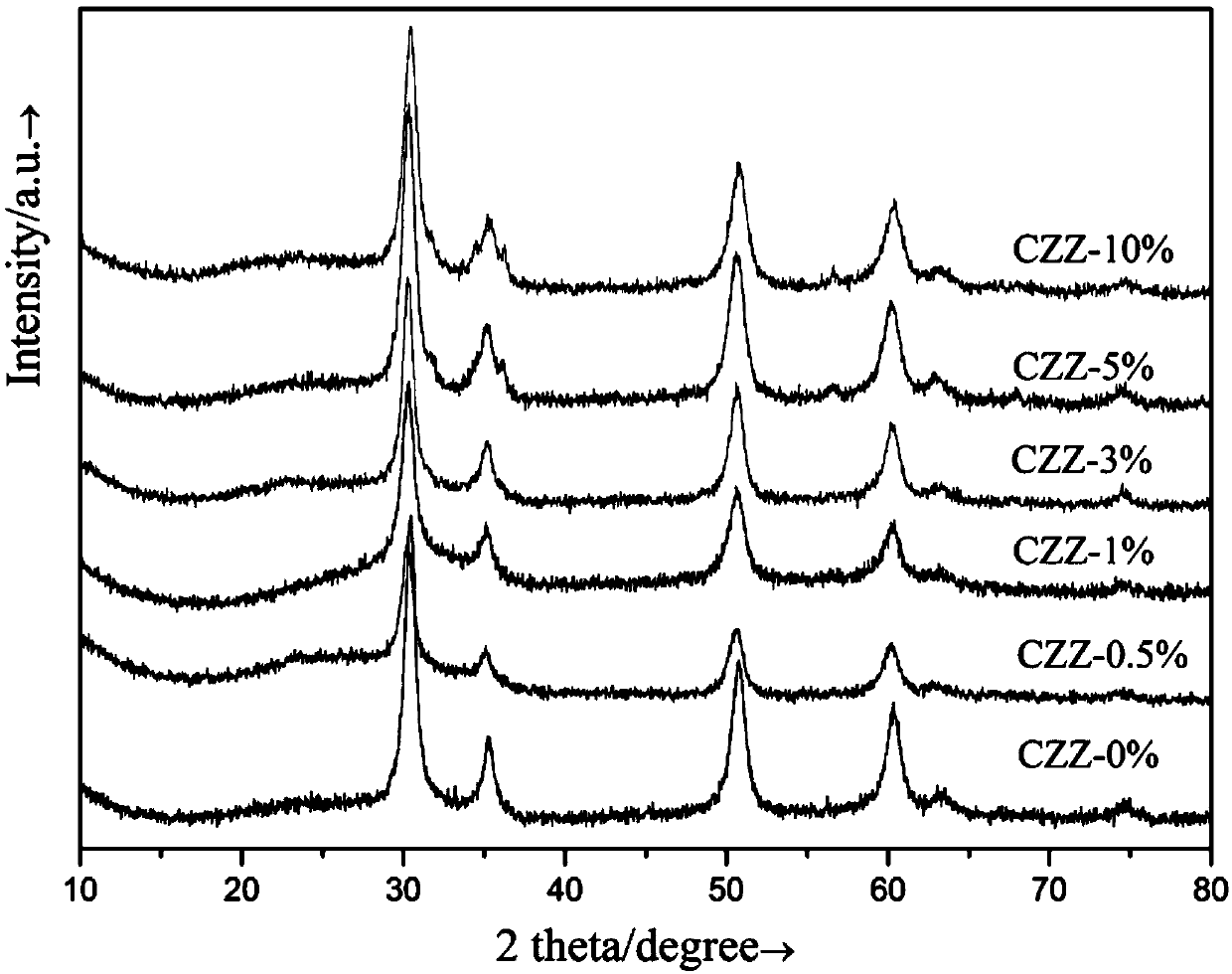

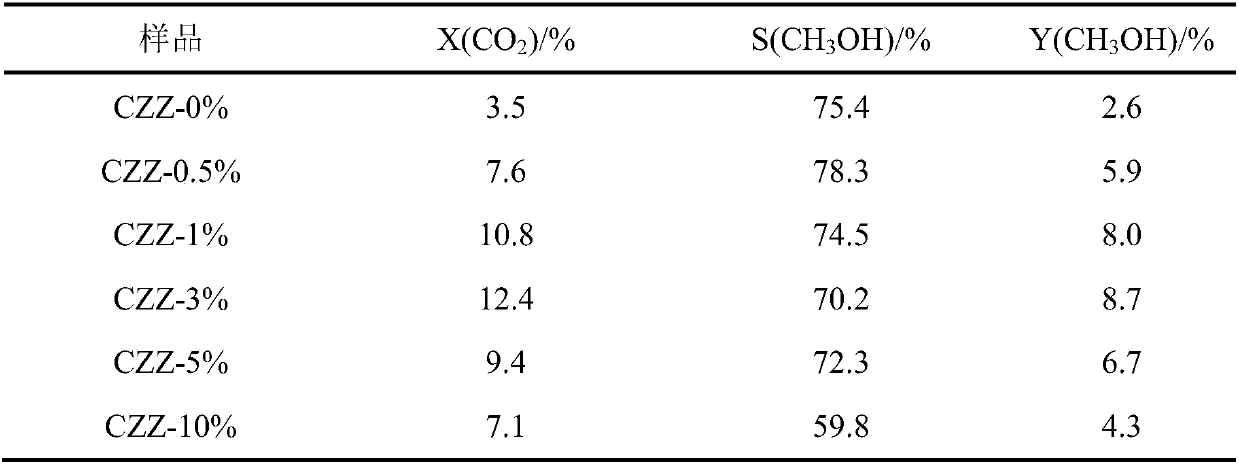

[0023] Copper-doped ZnO-ZrO of the present invention 2 The solid solution catalyst is prepared by the following method:

[0024] (1) Adding Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O was dissolved in deionized water to prepare a mixed solution of metal nitrate, and make it completely dissolved and mixed; wherein, the raw material Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 In O, the molar percentage of Cu is 0%~10%, but does not include 0; The molar ratio of Zn and Zr is Zn:Zr=1:4;

[0025] (2) Under the reaction temperature of 50~90 DEG C, the metal nitrate mixed solution that step (1) obtains and the Na that concentration is 0.5~1mol / L 2 CO 3 The solution is added dropwise into the reaction vessel by means of co-current addition, and magnetic stirring is used to promote the formation of precipitates, and the pH of the titration end point is kept at 7-8; Aging at reaction temperature for 3 to 5 hours;

[0026] (3) ...

Embodiment 1

[0055] (1) Weigh Zn(NO 3 ) 2 ·6H 2 O 1.49g and Zr(NO 3 ) 4 ·5H 2 O 8.59g, weigh Cu(NO 3 ) 2 ·3H 2 O 0.03g was dissolved in deionized water to prepare Na with a concentration of 0.5mol / L 2 CO 3 solution;

[0056] (2) At a reaction temperature of 70°C, slowly drop the above solution in parallel in a three-necked flask, and at the same time perform magnetic stirring to control the pH value of the solution at the end point of the titration to be about 7.5. After the titration is completed, continue stirring for 1 hour and then stop stirring. Stand still at the reaction temperature for 3 hours, centrifugally filter the solution at a rotating speed of 10000r / min, add deionized water to wash 3 times, and obtain a solid precipitate;

[0057] (3) drying in a vacuum oven at 105° C. for 12 hours to obtain a copper-doped zinc-zirconium solid solution catalyst precursor.

[0058] (4) The catalyst precursor obtained after drying was calcined in a tube furnace at 500°C for 3 hours...

Embodiment 2

[0060] (1) Weigh Zn(NO 3 ) 2 ·6H 2 O 1.49g and Zr(NO 3 ) 4 ·5H 2 O 8.59g, weigh Cu(NO 3 ) 2 ·3H 2 O 0.06g was dissolved in deionized water to prepare Na with a concentration of 0.5mol / L 2 CO 3 solution;

[0061] (2) At a reaction temperature of 70°C, slowly drop the above solution in parallel in a three-necked flask, and at the same time perform magnetic stirring to control the pH value of the solution at the end point of the titration to be about 7.5. After the titration is completed, continue stirring for 1 hour and then stop stirring. Stand still at the reaction temperature for 3 hours, centrifugally filter the solution at a rotating speed of 10000r / min, add deionized water to wash 3 times, and obtain a solid precipitate;

[0062] (3) drying in a vacuum oven at 105° C. for 12 hours to obtain a copper-doped zinc-zirconium solid solution catalyst precursor.

[0063] (4) The catalyst precursor obtained after drying was calcined in a tube furnace at 500°C for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com