Separation method for coal-based fischer-tropsch olefin

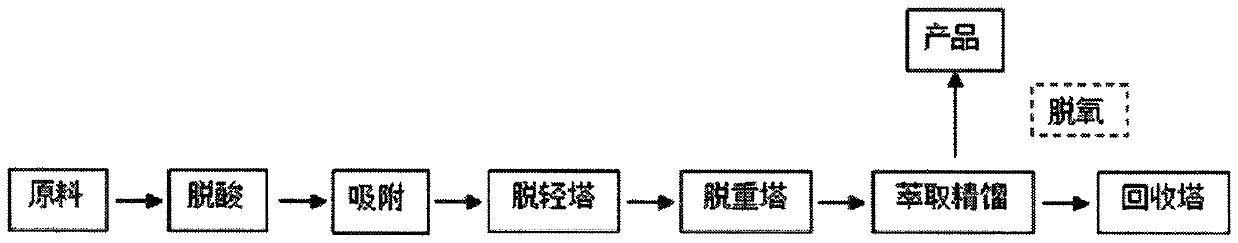

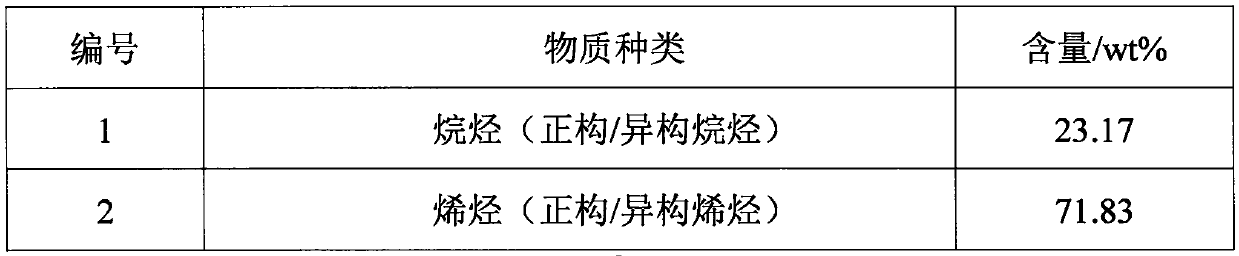

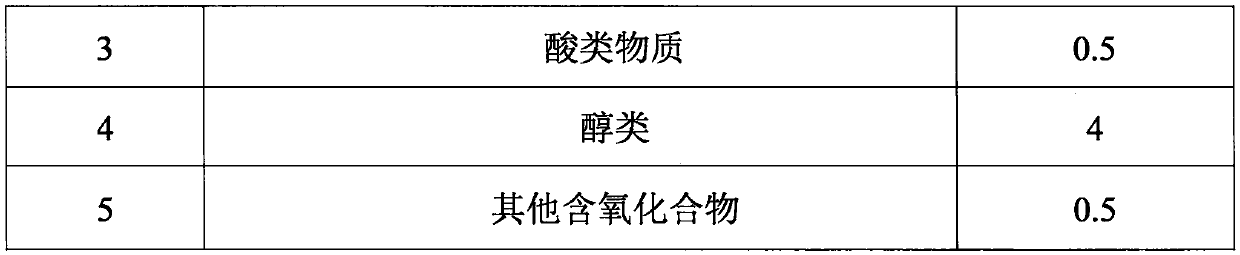

A technology for coal-based fees and olefins, which is used in the purification/separation of hydrocarbons, adsorption purification/separation, chemical instruments and methods, etc. It can solve the problems of complex raw material composition, poor product diversity, and poor production continuity, and achieve a simple process flow. , Product diversity is strong, and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The carbon number of the target olefin is 8, the extraction agent is dimethyl phthalate, and the operating parameters of the light removal tower are: the temperature of the tower bottom is 58°C, the operating pressure is 21.3kpa, the number of trays is 65, the feed position is 45, and the reflux ratio It is 4:1; the operating parameters of the weight-removing tower are: tower kettle temperature 80°C, operating pressure 21.3kpa, number of trays 55, feed position 35, reflux ratio is 5:1; extractive distillation column operating parameters are: tower kettle The temperature is 85°C, the operating pressure is 21.3kpa, the number of trays is 40, the feed position is 18, and the reflux ratio is 5.5:1; the mass ratio of extraction agent to raw material is 5:1; The pressure is 21.3kpa, the number of trays is 45, the feed position is 23, and the reflux ratio is 4.5:1. The purity of the olefin product is above 99.7wt%, the content of oxygen-containing compounds is less than 10ppm, ...

Embodiment 2-11

[0053] The basic treatment method is the same as in Example 1, but the specific operating parameters are different, as shown in Table 4-Table 8.

Embodiment 12

[0055] The product that embodiment 2-11 extraction rectification obtains is passed into the adsorption tower that molecular sieve is housed, carries out deoxidation treatment, carries out further adsorption separation to oxygenate (adsorbent is 5A molecular sieve, and the mass ratio of adsorbent and oil is 1 : 1), operating temperature is 40 DEG C, pressure 0.5Mpa obtains product purity all higher than 99.7wt%, oxygen-containing compound content is lower than 1ppm.

[0056] Table 4 Example 2-3 target olefin carbon number and process parameters

[0057]

[0058] Table 5 Example 4-5 target olefin carbon number and process parameters

[0059]

[0060]

[0061] Table 6 Example 6-7 target olefin carbon number and process parameters

[0062]

[0063]

[0064] Table 7 Example 8-9 target olefin carbon number and process parameters

[0065]

[0066]

[0067] Table 8 Example 10-11 target olefin carbon number and process parameters

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com