High-quality cleaning method for sugar juice

A high-quality, sugar juice technology, applied in the purification of sugar juice, the use of physical methods to purify, sucrose production, etc., can solve the low; Chinese patent (application number and other problems, achieve less conversion of sucrose, short residence time, remove high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

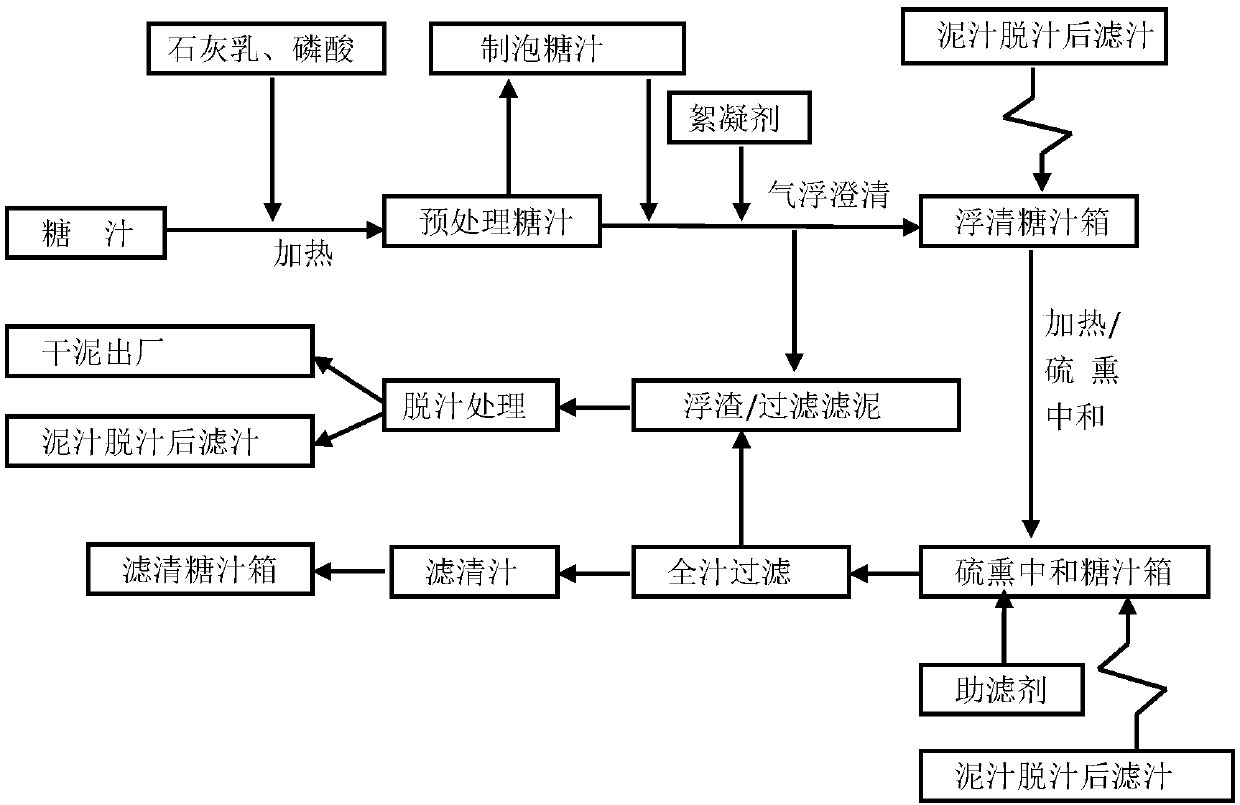

Method used

Image

Examples

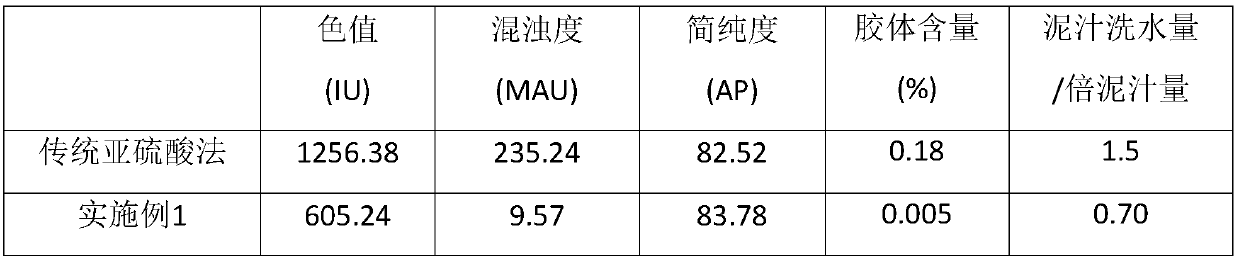

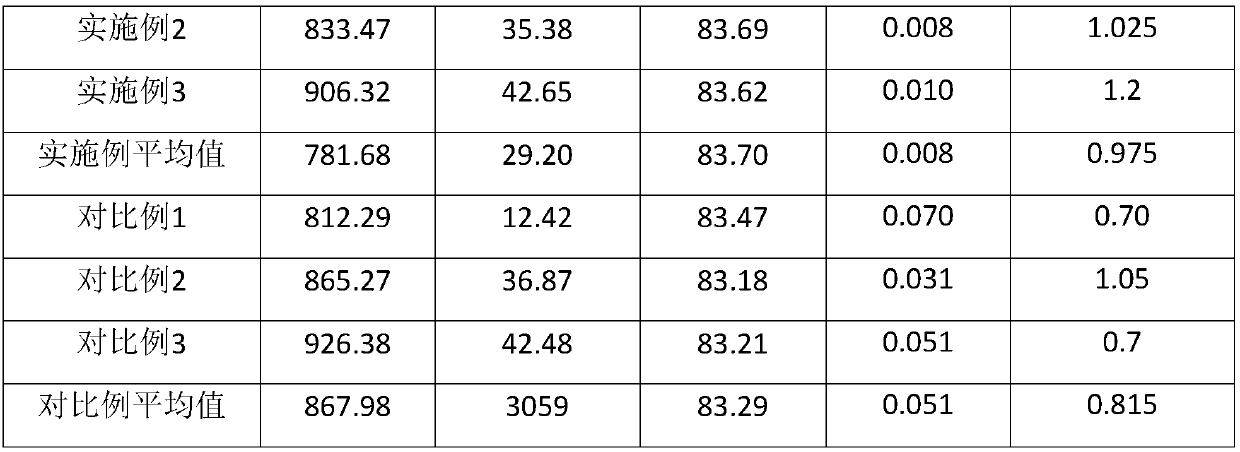

Embodiment 1

[0031] A high-quality cleaning method for sugar juice, the specific steps are as follows:

[0032] (1) Sugar juice pretreatment: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice to 350ppm, control the pH value of the sugar juice at 11.0, and adjust the pH value by adding ash in stages, that is, add ash to the pH first Control the value at 8.5, react for 2 minutes, then add ash again to control the pH value at 11.0, and control the primary heating temperature at 35°C;

[0033] (2) Low-temperature air flotation clarification of sugar juice: divide the pretreated sugar juice into two parts, one-fourth of the sugar juice is prepared for foaming, and after foaming, the sugar juice is mixed with other sugar juice and added with polyacrylamide flocculant 2ppm, enter the coagulation reactor for full reaction, the fully reacted sugar juice is sent to the floater for air flotation and clarification treatment, the floating cl...

Embodiment 2

[0037] A high-quality cleaning method for sugar juice, the specific steps are as follows:

[0038] (1) Sugar juice pretreatment: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice to 400ppm, control the pH value of the sugar juice at 10.8, adjust the pH value by adding ash in stages, that is, add ash to the pH first Control the pH value at 7.5, react for 2 minutes, then control the pH value at 9.0 after adding ash again, and control the primary heating temperature at 40°C;

[0039] (2) Low-temperature air flotation clarification of sugar juice: divide the pretreated sugar juice into two parts, wherein a quarter of the sugar juice is prepared for foaming, and after the foaming, the sugar juice is mixed with another sugar juice and added with 3 ppm of bioflocculant, Enter the coagulation reactor to fully react, and the fully reacted sugar juice is sent to the floater for air flotation and clarification treatment, the f...

Embodiment 3

[0043] A high-quality cleaning method for sugar juice, the specific steps are as follows:

[0044] (1) Sugar juice pretreatment: add lime milk and phosphoric acid to the sugar juice, adjust the total phosphoric acid value in the sugar juice to 300ppm, control the pH value of the sugar juice at 10.5, and adjust the pH value by adding ash in stages, that is, add ash to the pH first Control the pH value at 8.8, react for 2 minutes, then control the pH value at 10.5 after adding ash again, and control the primary heating temperature at 45°C;

[0045] (2) Low-temperature air flotation clarification of sugar juice: divide the pretreated sugar juice into two parts, one-fourth of the sugar juice is prepared for foaming, and after foaming, the sugar juice is mixed with another sugar juice and then added with modified chitosan The flocculant is 5ppm, and enters the coagulation reactor to fully react, and the fully reacted sugar juice is sent to the floater for air flotation and clarific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com