Preparation method of high tensile modulus polymer nano composite fiber based on electrospinning technology

A nanocomposite fiber and electrospinning technology, which is applied in the field of preparation of high tensile modulus polymer nanocomposite fibers, can solve the problems of high filling volume of polymer nanocomposite fibers and high requirements for nanoparticle processing, and achieve interaction Force enhancement, low equipment requirements, high Young's modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

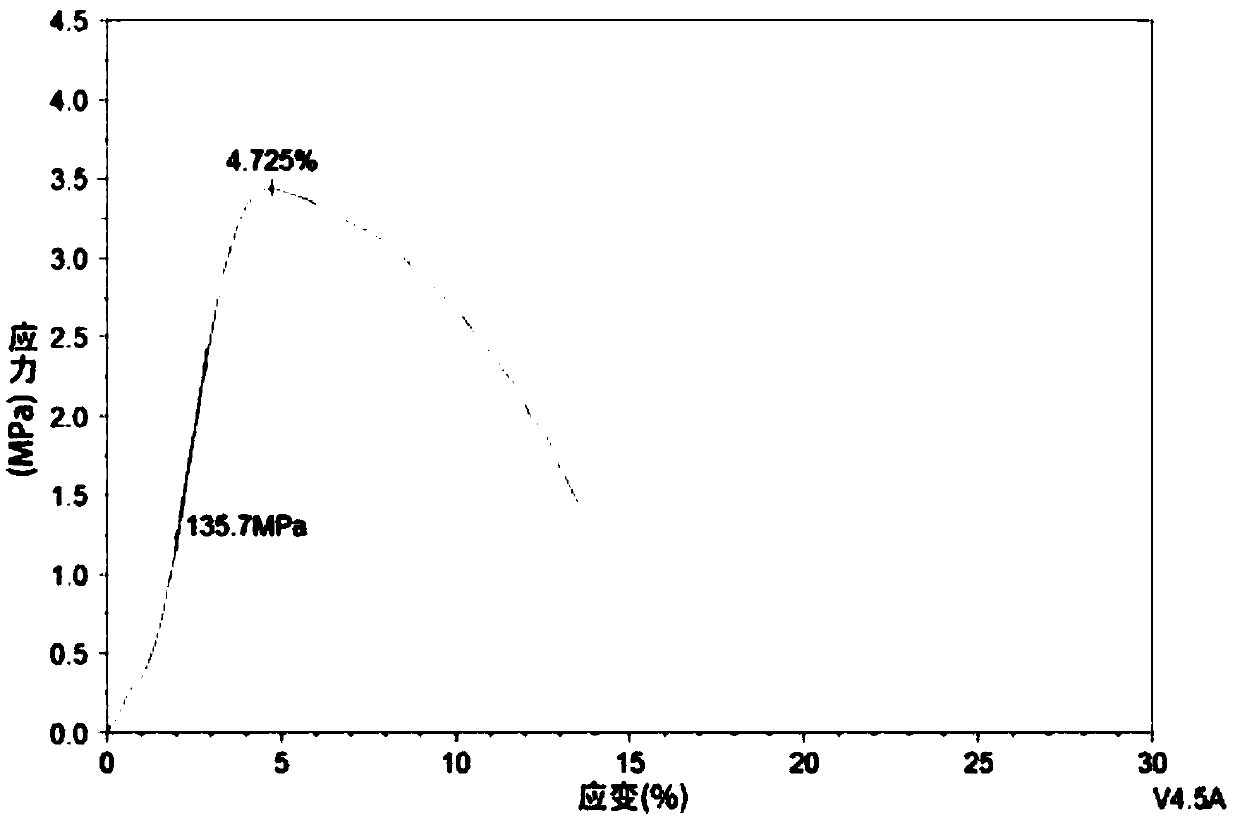

Embodiment 1

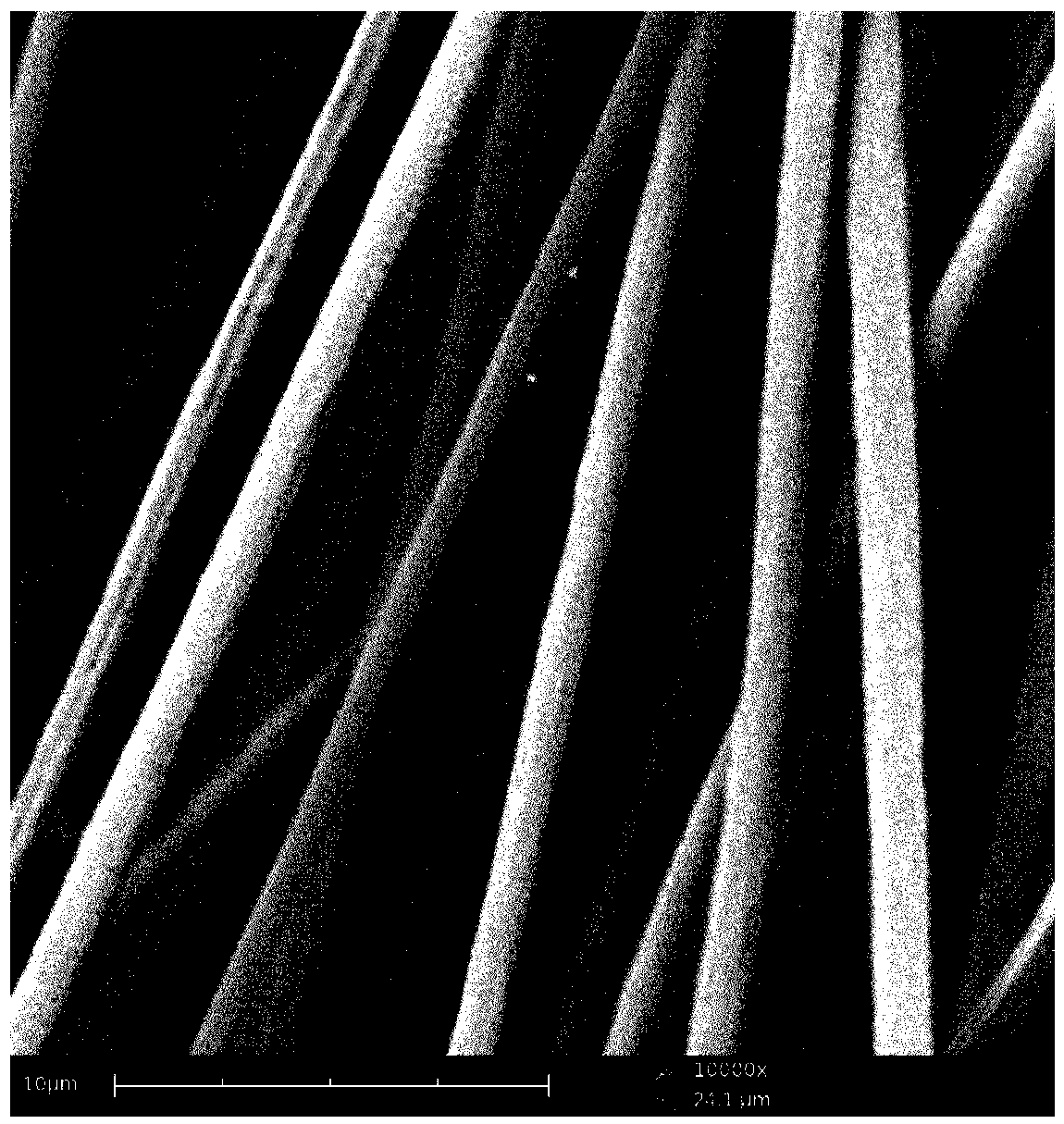

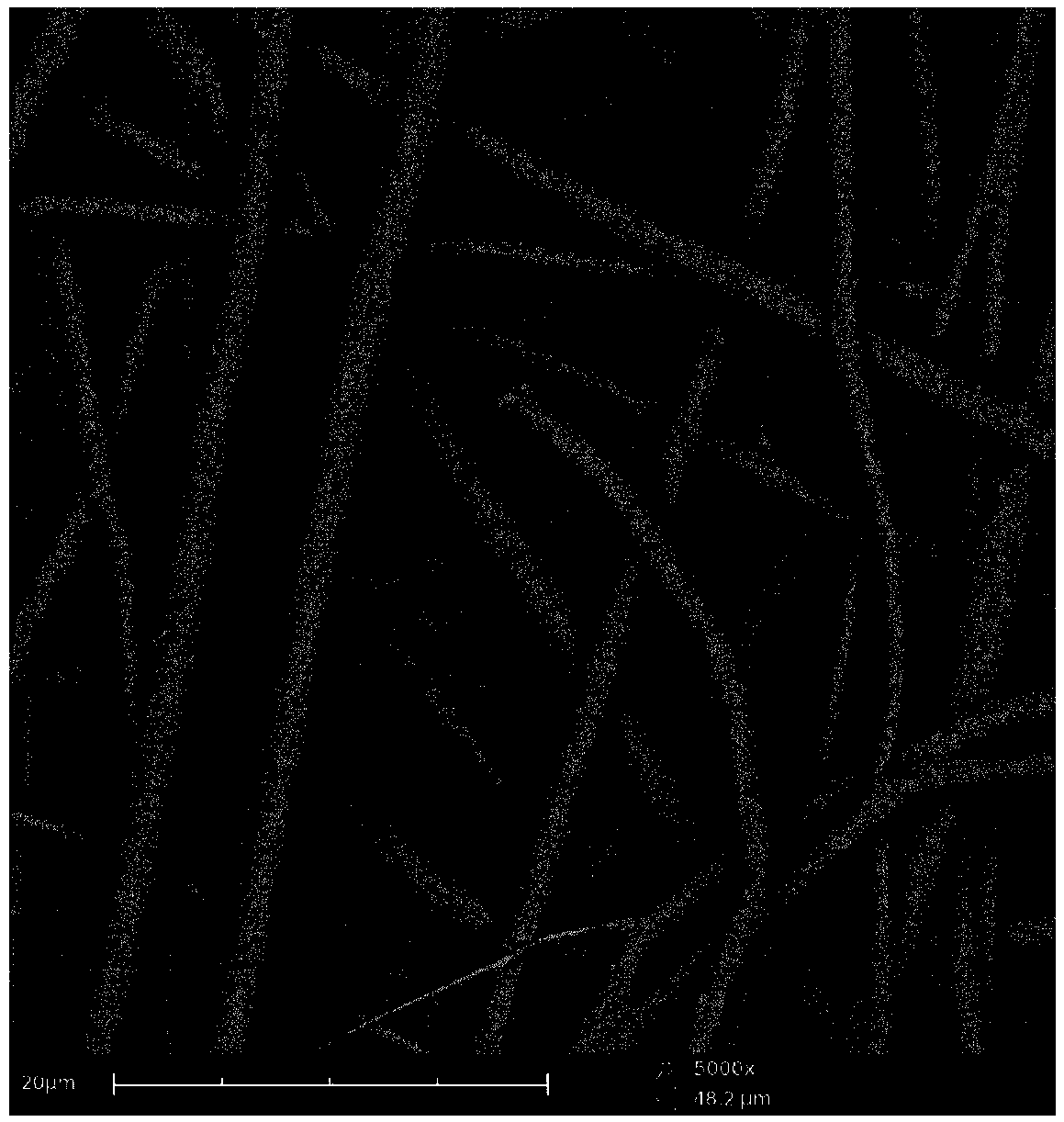

[0024] In a nitrogen atmosphere, place the zinc foil in a quartz tube (120 cm long and 10 cm in diameter) at 700 °C and slowly feed oxygen and saturated water vapor at a rate of 50 standard milliliters per minute to participate in the reaction (oxygen and saturated water vapor) The water vapor volume ratio is 1:1, that is, the feed rate of oxygen and saturated water vapor is 25 standard ml / min), the oxygen flow rate and reaction time are strictly controlled to obtain a narrow size distribution range, the average arm diameter is within about 25nm, and the average arm diameter Tetragonal pyramidal zinc oxide nanoparticles with a length of about 70nm.

[0025] Dissolve 2.0g of coupling agent (γ-aminopropyltriethoxysilane) in 50mL of water-ethanol mixed solution (the volume ratio of water and ethanol is 1:1), ultrasonically disperse at room temperature for 1h, and then add 0.8g of the above The synthesized tetragonal pyramid-shaped zinc oxide nanoparticles were heated and stirred ...

Embodiment 2

[0029] In a nitrogen atmosphere, place the zinc foil in a quartz tube (120 cm long and 10 cm in diameter) at 700 °C and slowly feed oxygen and saturated water vapor at a rate of 50 standard milliliters per minute to participate in the reaction (oxygen and saturated water vapor) The water vapor volume ratio is 1:1, that is, the feed rate of oxygen and saturated water vapor is 25 standard ml / min), the oxygen flow rate and reaction time are strictly controlled to obtain a narrow size distribution range, the average arm diameter is within about 25nm, and the average arm diameter Tetragonal pyramidal zinc oxide nanoparticles with a length of about 70nm.

[0030] Dissolve 2.0 g of coupling agent (pyrophosphate titanate) in 50 mL of water-ethanol solution (volume ratio of water and ethanol is 1:1), ultrasonically disperse at room temperature for 1 hour, and then add 0.8 g of the tetragonal pyramid synthesized above. Zinc oxide nanoparticles were heated and stirred at 60° C. for 2 hou...

Embodiment 3

[0034] In a nitrogen atmosphere, place the zinc foil in a quartz tube (120 cm long and 10 cm in diameter) at 700 °C and slowly feed oxygen and saturated water vapor at a rate of 50 standard milliliters per minute to participate in the reaction (oxygen and saturated water vapor) The water vapor volume ratio is 1:1, that is, the feed rate of oxygen and saturated water vapor is 25 standard ml / min), the oxygen flow rate and reaction time are strictly controlled to obtain a narrow size distribution range, the average arm diameter is within about 25nm, and the average arm diameter Tetragonal pyramidal zinc oxide nanoparticles with a length of about 70nm.

[0035] Dissolve 2.0 g of coupling agent (γ-aminopropyltriethoxysilane) in 50 mL of water-ethanol solution, ultrasonically disperse at room temperature for 1 h, add 0.8 g of synthesized tetragonal pyramid-shaped zinc oxide nanoparticles, and store at 60 °C After heating and stirring at low temperature for 2 hours, it was filtered, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com