Method for detecting monomethylene diurea and dimethylene triurea in urea formaldehyde fertilizer

A technology of monomethylene diurea and dimethylene triurea is applied in the field of detection of different component contents in urea-formaldehyde fertilizers, which can solve the problems of increased detection cost, poor repeatability, long time period, etc. The effect of reducing nitrogen loss, simple operation and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Obtaining pure products of monomethylene diurea and dimethylene triurea:

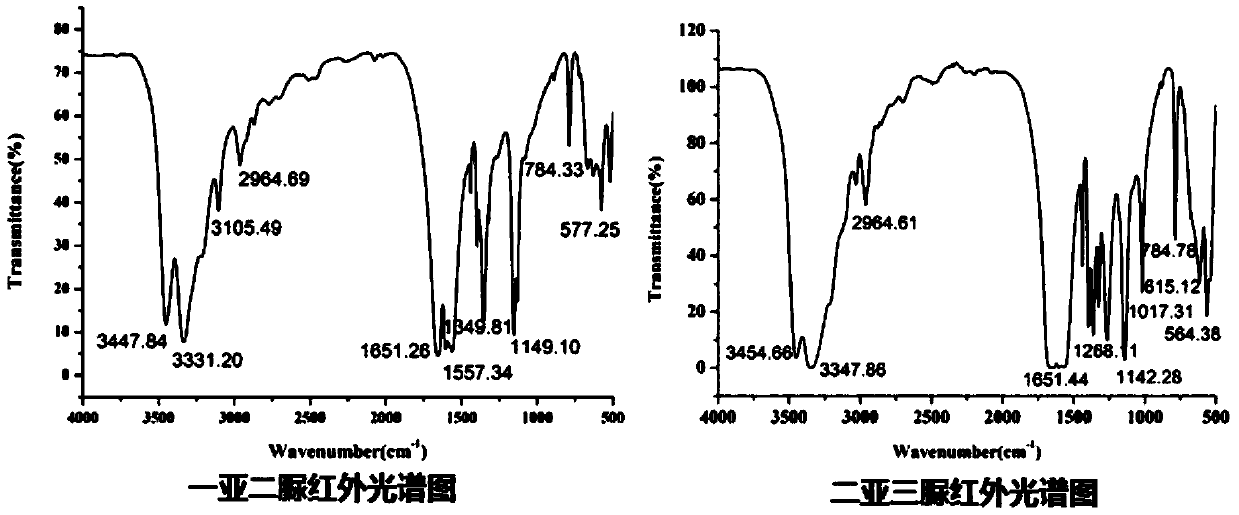

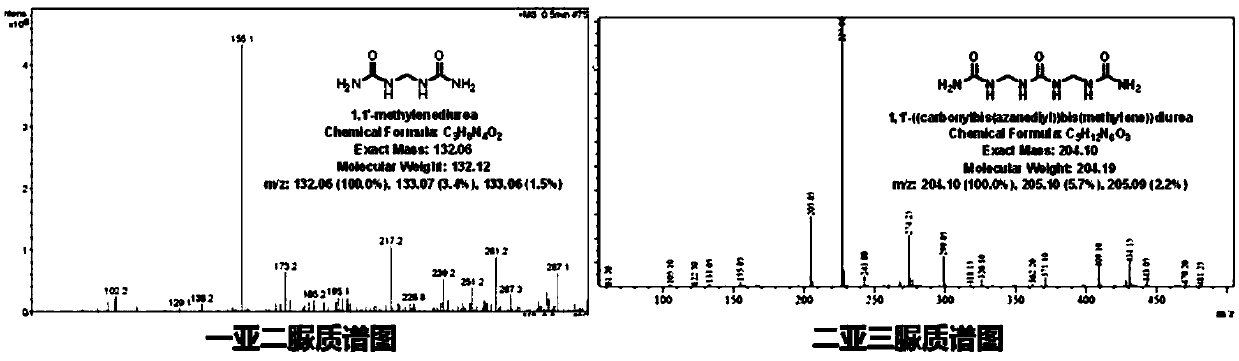

[0024] Mix urea and paraformaldehyde as raw materials according to a mass ratio of 10:1, use 50mL of water as a solvent, reflux at 70°C for 10 minutes, rotary evaporate, and dry to obtain a mixture of diurea and ditriurea, and then use it several times 50ml of water was recrystallized and separated to obtain monomethylene diurea, and the remaining solution was rotary evaporated to obtain the target product of ditriurea, which was characterized by infrared spectroscopy and mass spectrometry (see attached figure 1 And attached figure 2 ), it can be seen from the infrared spectrum that 1650cm -1 The peak is the characteristic peak of the carbonyl structure of di-diurea and di-triurea, 3447-3331cm -1 and 1557cm -1 for NH 2 and NH characteristic peaks, m / z=155 is a methylene diurea (M + Na), m / z=205 is ditrisourea (M + H), so it can be concluded that the synthesized substances are indeed pure s...

Embodiment 2

[0029] Urea-formaldehyde fertilizer sample processing and testing methods are as follows:

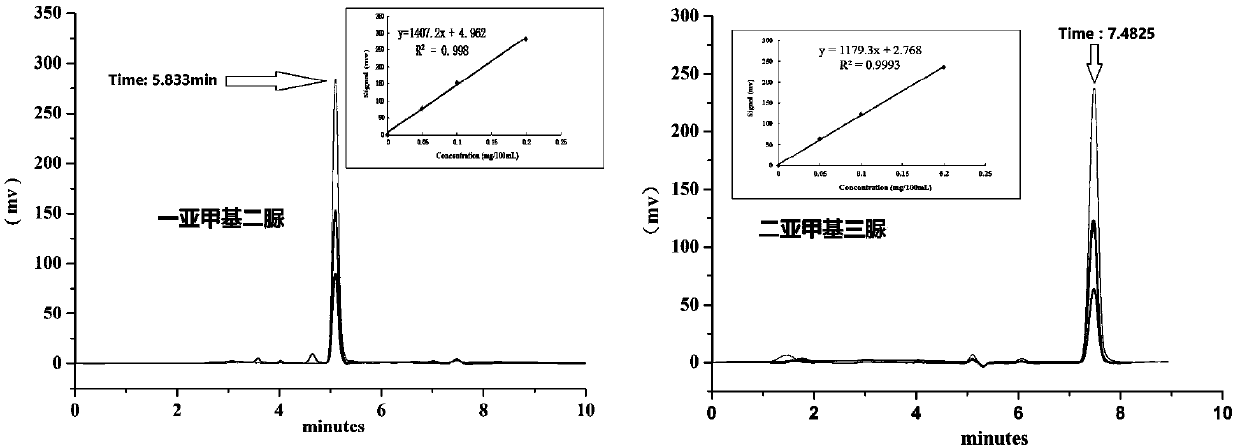

[0030] Accurately weigh 0.5000g of sample 1, put it in a 100mL volumetric flask, prepare a standard solution with a mixture of methanol and water at a volume ratio of 9:1, and set the volume to the mark. Take 5 mL of the above-mentioned sample solution and place it in a centrifuge tube, and use a centrifuge to adjust the rotation speed to 4000 rpm for 15 min. Pass through a 0.45um filter membrane to form a solution to be tested after filter membrane pretreatment for liquid chromatography testing. Test conditions: organic mobile phase 90%, inorganic mobile phase 10%, organic mobile phase is methanol, inorganic phase is water, flow rate is set to 1.0mL / min, injection volume is set to 10uL, chromatographic column is selected as C18 chromatographic column, Column temperature 25°C, detection wavelength of UV detector: λ ex = 240nm. Chromatogram after detection (see attached Figure 4 ) c...

Embodiment 3

[0034] Column temperature is set as 40 ℃, and other conditions are the same as embodiment 2, and the result peak time slightly changes, and other is constant, the relative standard deviation of gained parallel sample<8%, the relative standard deviation<5% of repeatability test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com