Method for increasing humic acid content of organic solid waste compost by using sustainable catalytic material

A technology of organic solid waste and catalytic materials, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts. It can solve the problems of cumbersome, low humic acid content, and complicated composting operations, and achieve nitrogen reduction. Loss, increase content, and promote the effect of compost maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]In the present invention, the modified bio-carbon is preferably prepared from the following steps: under nitrogen protection, with ammonia gas is modified atmosphere, the bio-carbon is treated at 680 to 70 min at 680 to 70 min, and nitrogen modification is obtained. bio-charcoal. The ammonia gas has a gas flow of 340 to 360 mL / min, more preferably 350 mL / min. The temperature of the treatment is preferably 700 ° C. The particle diameter of the biocar is preferably from 2 to 0.5 mm, more preferably from 1 to 0.5 mm. The temperature of the treatment is preferably 60 min.

[0038]In the present invention, the manganese dioxide and the biocarbon joint modified material are preferably prepared by the following steps: mixing bio, potassium permanganate, and deionized water, adding tetrahydrate acetate to the mixture. After the solution, after manganese dioxide precipitate, heated to 75 to 85 ° C for 25 to 35 ° C, and the carbon dioxide of manganese dioxide was collected, washed, and...

Embodiment 1

[0044]1. Experimental materials: rice straw comes from the residue of rice harvesting after the previous year; chicken manure is from the fresh chicken farm; straw degradation fungicides purchase straw compulsory agents produced from the Heilongjiang Mysteria Food Kang Technology Development Co.

[0045]2. A method of improving the content of organic solid waste stacking using sustainable functional materials, composed of the following steps:

[0046](1) Before the start of the compost, the straw is obtained to 2 to 3 cm long. Subsequently to adjust the carbon nitrogen ratio of 25% by chicken manure, the moisture content of the distilled water regulate material is about 65%, and the high-efficiency hydrolysis of the wood cellulose in the material. The amount of inoculation is 2% of the weight of the material.

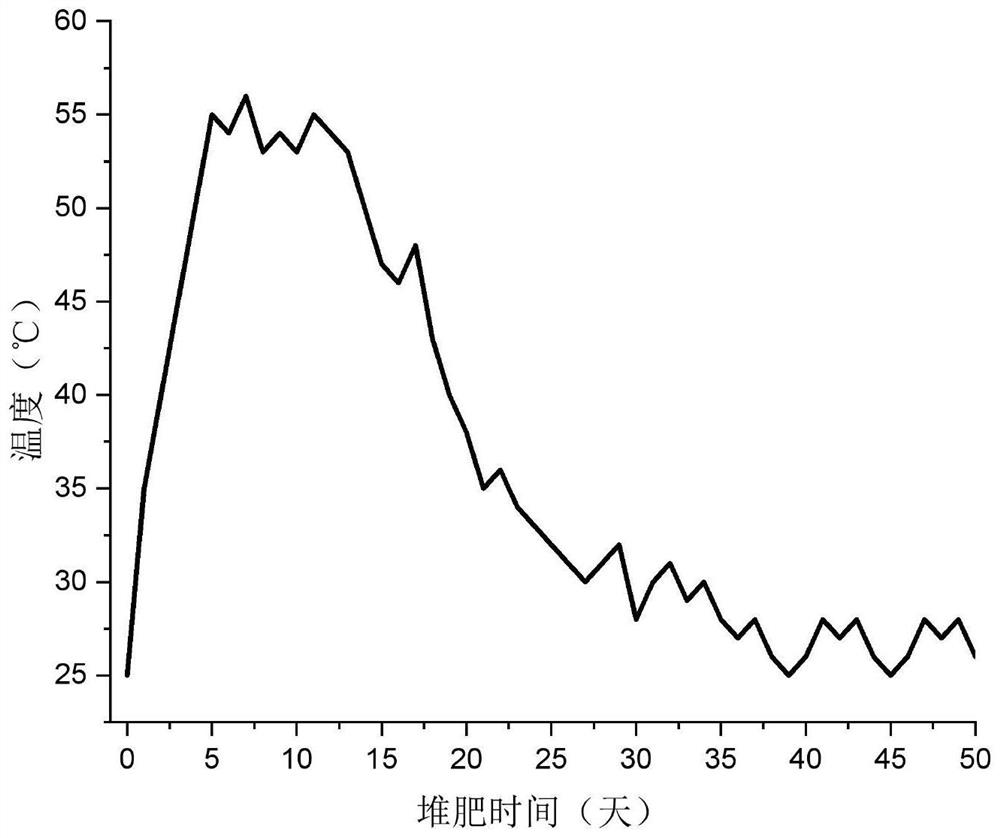

[0047](2) The high temperature period has just been completed, and the 5 ‰ of the manganese dioxide catalyzed material that has a weight loss is added, and the compost is continuing.

[...

Embodiment 2

[0052]Experimental materials:

[0053]Chicken manure is derived from the chicken farm, and the compost is carried out after drying.

[0054]2. A method of improving the content of organic solid waste stacking using sustainable functional materials, which consists of the following steps:

[0055](1) Before the start of the compost, the chicken manure was obtained to about 2 cm to 2 cm, followed by regulating the carbon nitrogen ratio of about 30, and the distilled water regulated material moisture was about 65%.

[0056](2) The 2 ‰ of the stache is added to the end of the stacked bracket catalytic material when the high temperature period is just ended.

[0057](3) After the completion of the compost, the material is removed, remove the residual residue attached to the surface, the catalytic material can be used in other material compost, achieving sustainable use.

[0058]After the above experiment, a 60-day compost experiment was carried out in a control group, and the humic acid content of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com