Alkali metal surface in-situ treatment method and application thereof in secondary battery

An in-situ processing, metal technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of difficult application and high production cost, achieve continuous cracking and repair, solve safety problems, and improve ion channels. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

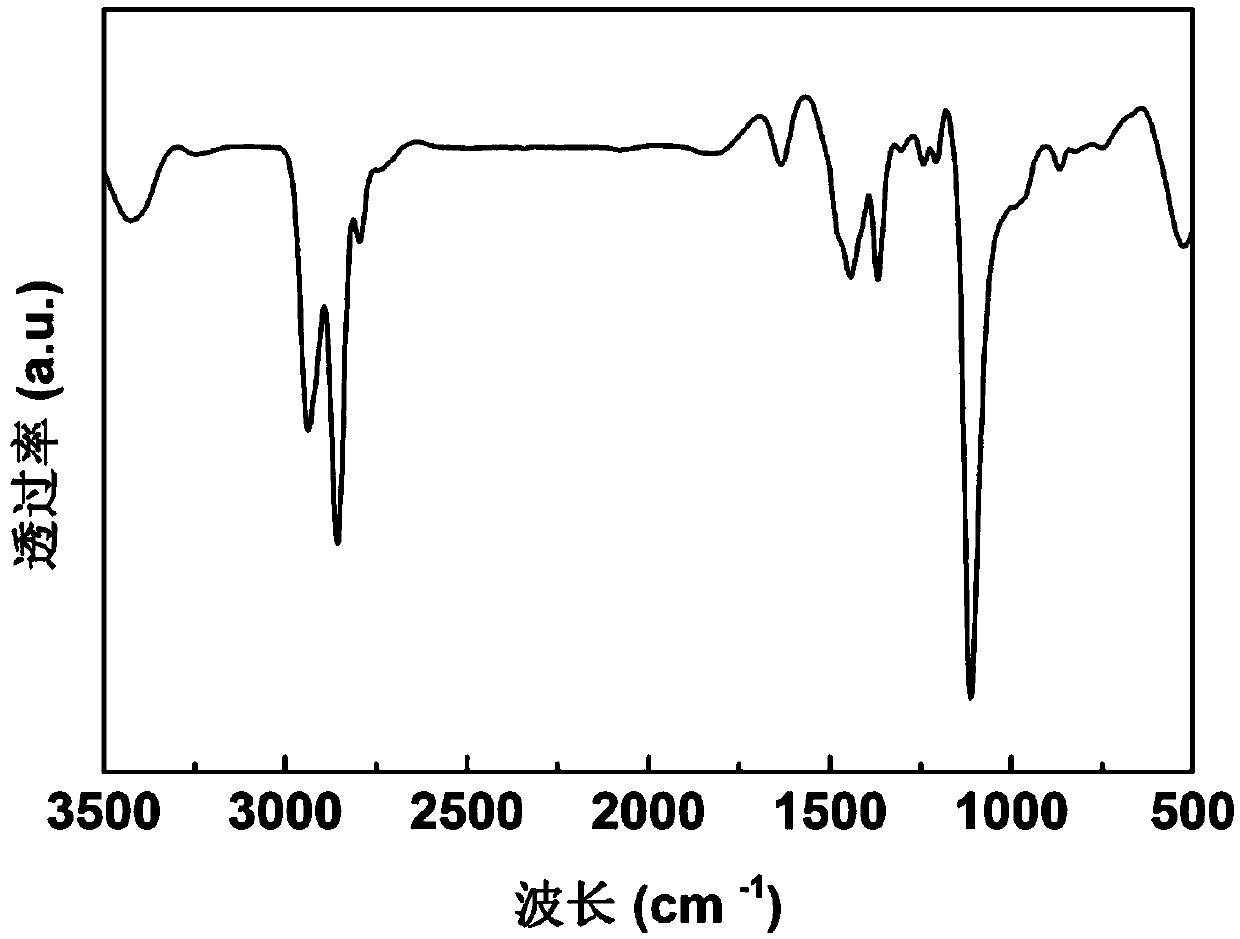

[0052] In a high-purity argon atmosphere, immerse the polished lithium sheet in dimethyl sulfoxide solution containing 0.05M tin tetrachloride for 5 minutes and react at a temperature of 20°C. Put the lithium sheet in pure 1,4-diox The hexacyclic solution was washed and allowed to evaporate. The composite film with polyepoxy polymer / alloy phase of the present invention can be obtained. Such as figure 1 Shown is the scanning electron microscope image of the processed lithium sheet. It can be seen from the image that the thickness of the composite film formed is about 10 μm.

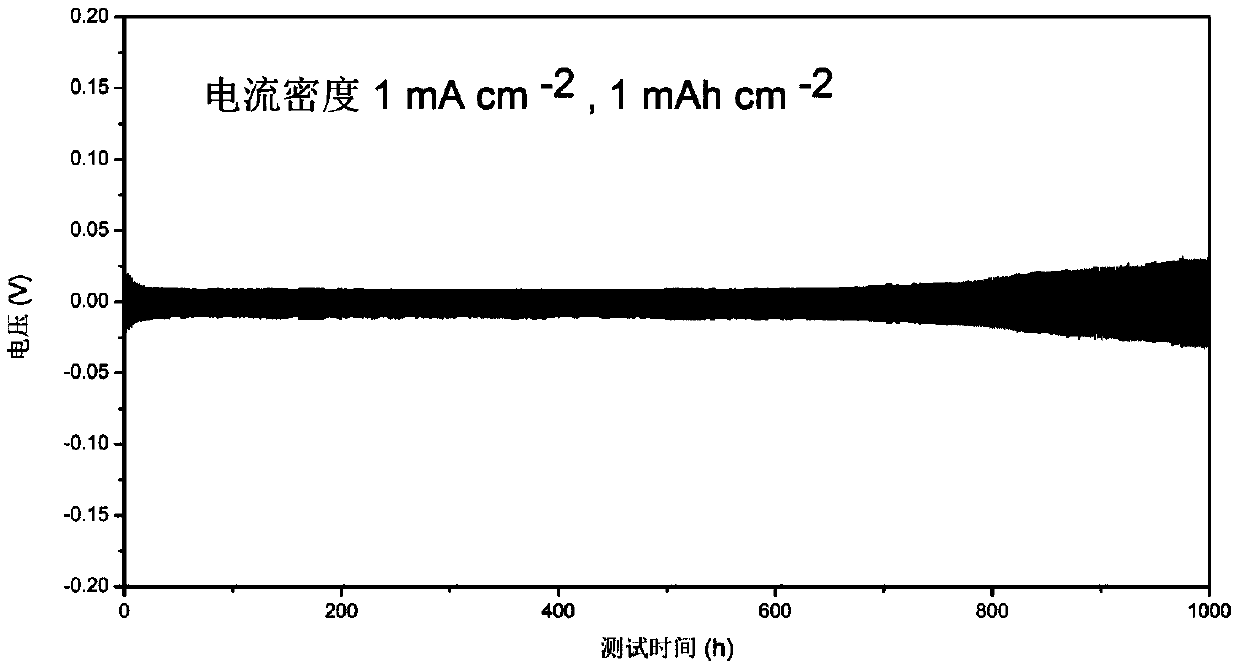

[0053] The above-mentioned lithium sheet with a protective film and the separator were assembled into a lithium-lithium symmetrical button cell in an argon-protected glove box, and the concentration of 1M bistrifluoromethanesulfonylimide lithium and 1% mass concentration of lithium nitrate were added. , 3-dioxolane and ethylene glycol dimethyl ether (volume ratio of 1:1) electrolyte.

[0054] Assemble t...

Embodiment 2

[0056] Other conditions are the same as in Example 1, except that the concentration of the treatment solution is 0.1M.

[0057] The button battery was assembled and tested in the same manner as in Example 1.

Embodiment 3

[0059] Other conditions are the same as in Example 1, except that the treatment liquid solute is tin dichloride.

[0060] The button battery was assembled and tested in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com