Preparing method of waste newspaper base charcoal

A technology of waste newspapers and biochar, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of wide sources, rich surface functional groups, and high ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

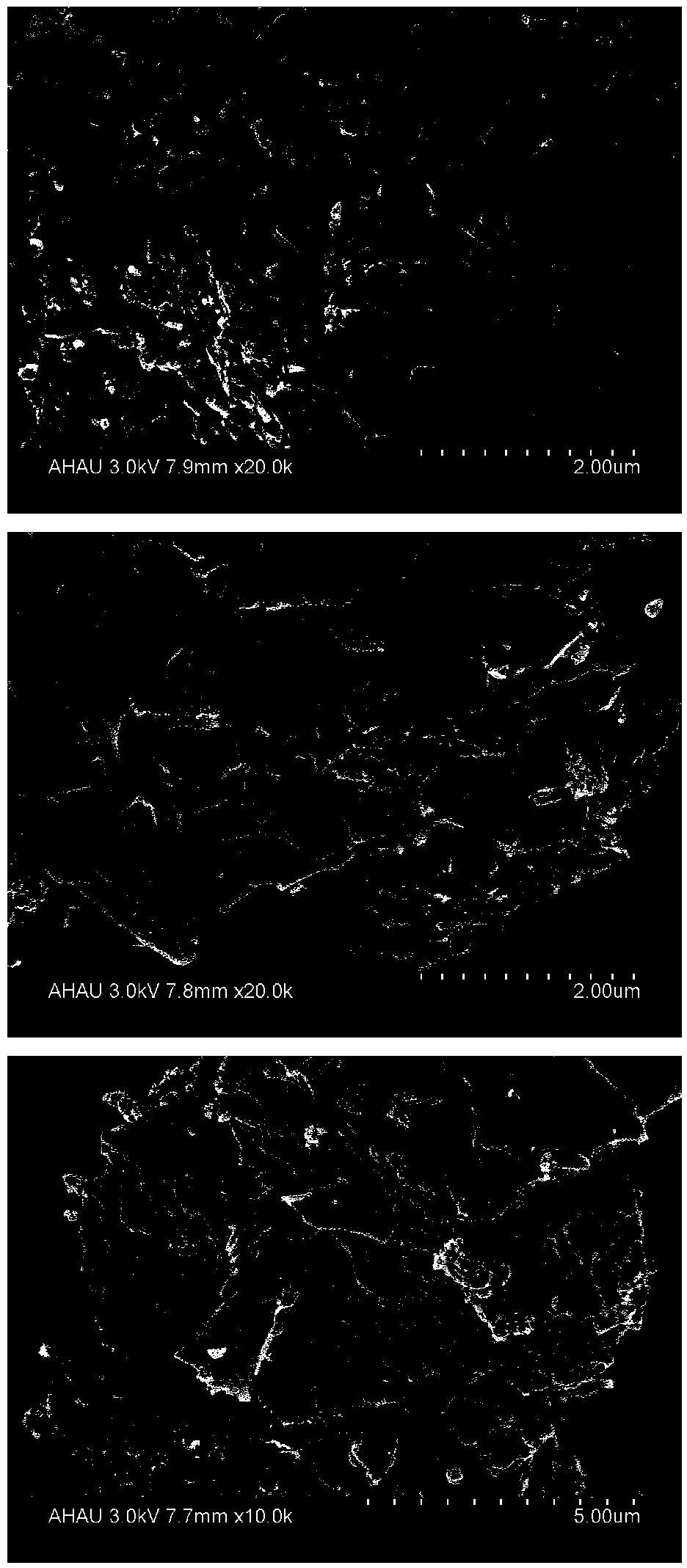

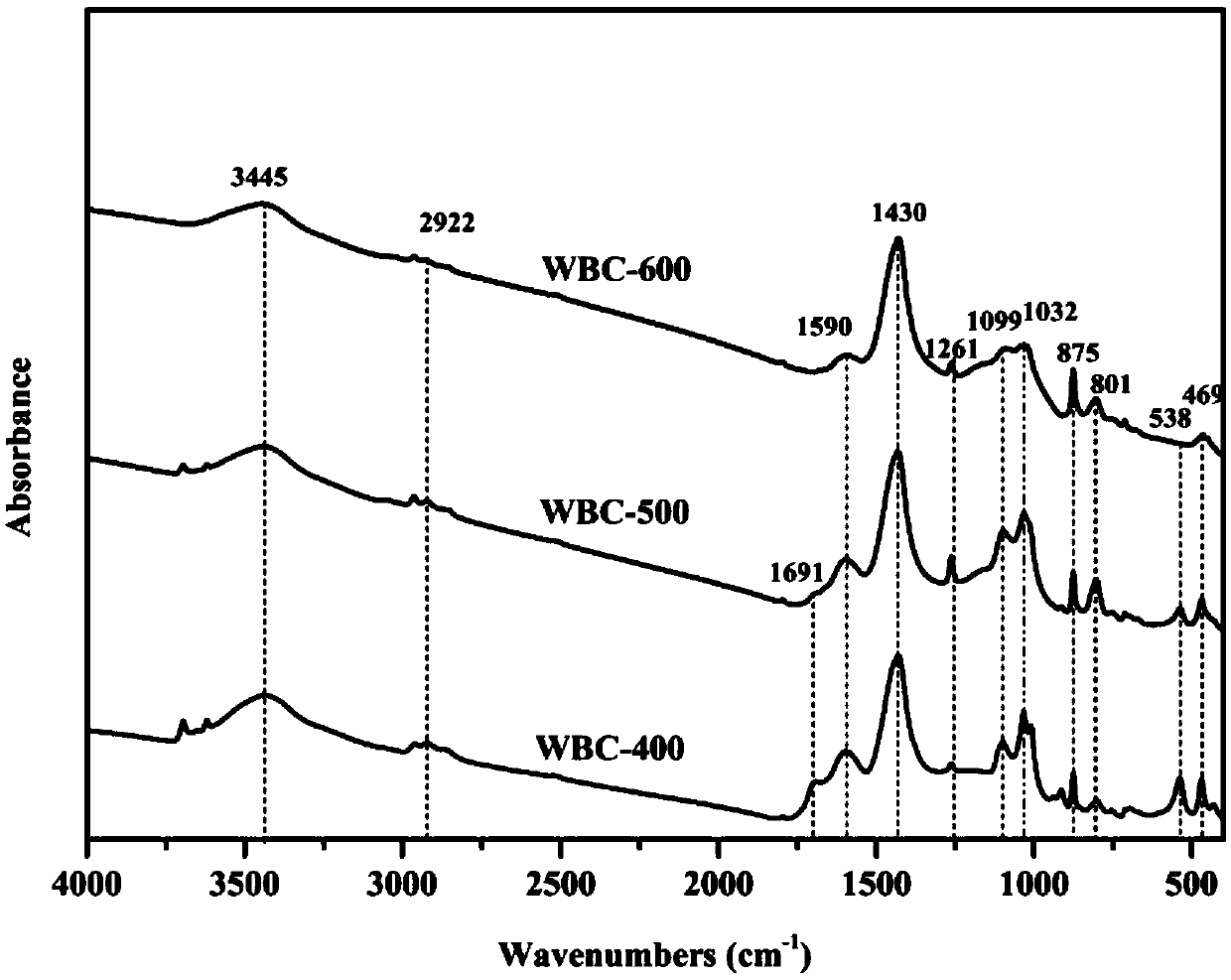

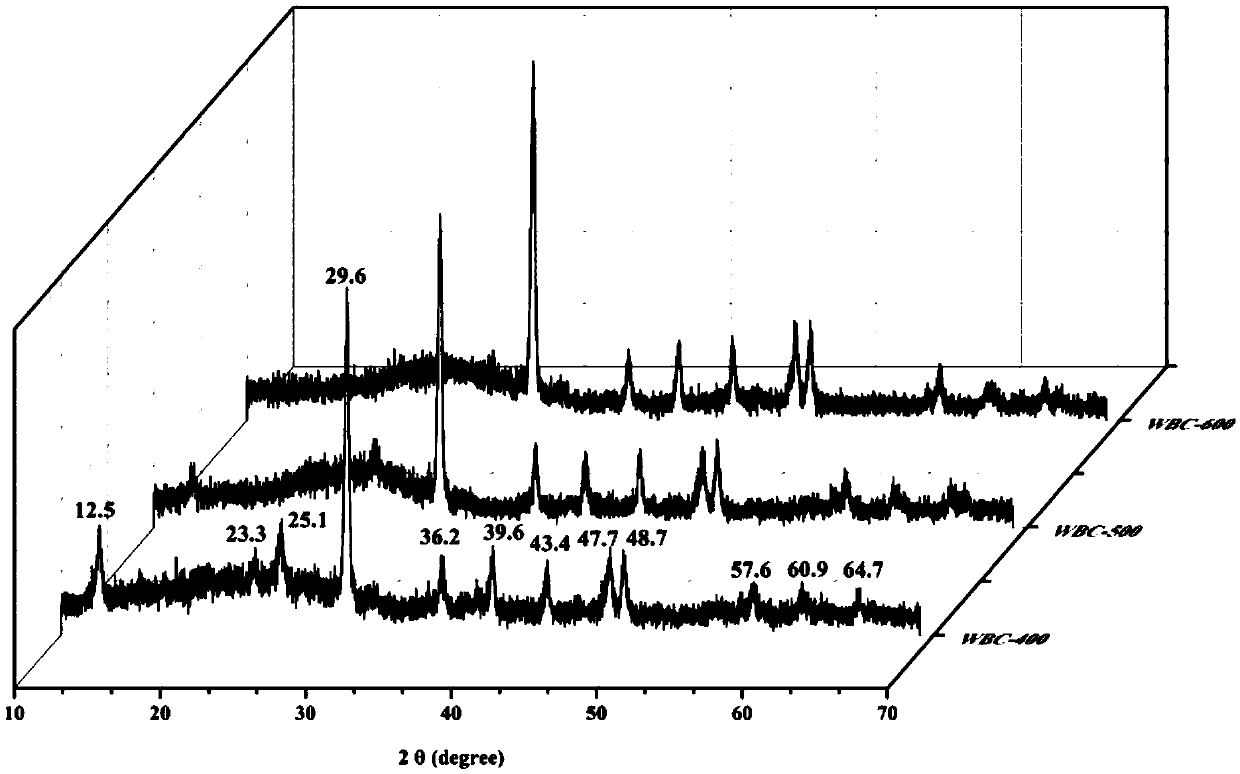

[0033] Preparation of waste newspaper-based biochar

[0034] (1) Grinding waste newspaper balls without any chemical treatment into powder, drying for subsequent use;

[0035] (2) Put the waste newspaper that has been ground into powder in a tube furnace, raise the temperature to 400° C. at a rate of 3° C. / min, and keep it warm for 3 hours to obtain the waste newspaper-based biochar;

[0036] (3) Grind the prepared waste newspaper-based biochar through a 200-mesh sieve, dry it for later use, and record it as WBC-400.

Embodiment 2

[0038] Preparation of waste newspaper-based biochar

[0039] (1) Grinding waste newspaper balls without any chemical treatment into powder, drying for subsequent use;

[0040] (2) Put the waste newspaper that has been ground into powder in a tube furnace, raise the temperature to 500° C. at a rate of 3° C. / min, and keep it warm for 2 hours to obtain the waste newspaper-based biochar;

[0041] (3) Grind the prepared waste newspaper-based biochar through a 200-mesh sieve, dry it for later use, and record it as WBC-500.

Embodiment 3

[0043] Preparation of waste newspaper-based biochar

[0044] (1) Grinding waste newspaper balls without any chemical treatment into powder, drying for subsequent use;

[0045] (2) Put the waste newspaper that has been ground into powder in a tube furnace, raise the temperature to 600° C. at a rate of 3° C. / min, and keep it warm for 1 hour to obtain the waste newspaper-based biochar;

[0046] (3) Grind the prepared waste newspaper-based biochar through a 200-mesh sieve, dry it for later use, and record it as WBC-600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com