A kind of cement ceiling board with adjustable humidity and preparation method thereof

A ceiling board, adjustable technology, applied in the direction of ceiling, building components, buildings, etc., can solve the problems of low breaking load, difficult to process and install, easy to break, etc., to improve surface roughness, easy to process and install, avoid easy broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

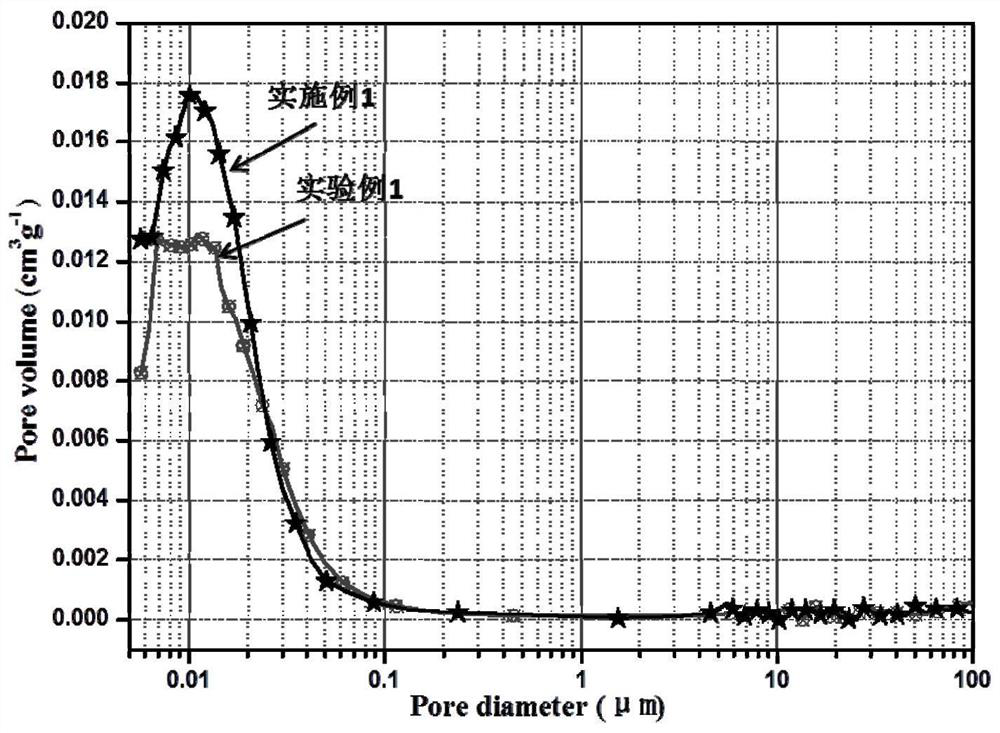

Embodiment 1

[0054] A method for preparing a humidity-adjustable cement ceiling board, comprising the following raw materials: material A, solution B, a humidity regulator and polypropylene fiber mesh cloth; wherein: the material A includes the following raw materials in parts by weight: 42.5 silicic acid 50 parts of salt cement, 35 parts of fly ash, 12 parts of papermaking sludge ash, 8 parts of ultrafine slag powder, and 1.0 part of polyvinylpyrrolidone. The solution B includes the following raw materials in parts by weight: 98.85 parts of water, 1.5 parts of KH570 type silane coupling agent, cuprous oxide modified graphene oxide (GO-Cu 2 O) 0.1 part, wherein; the GO-Cu 2 The loading amount of cuprous oxide in O is 5% (mol fraction), promptly adds 5mol cuprous oxide in every 100mol graphene oxide. The humidity regulator includes the following raw materials in parts by weight: 60 parts of zeolite, 15 parts of diatomite, 6 parts of sodium bentonite, and 0.5 part of water-absorbing resin. ...

Embodiment 2

[0065]A method for preparing a humidity-adjustable cement ceiling board, comprising the following raw materials: material A, solution B, a humidity regulator and polypropylene fiber mesh cloth; wherein: the material A includes the following raw materials in parts by weight: 42.5R silicon Salt cement 60 parts, fly ash 20 parts, papermaking sludge ash 15 parts, ultrafine slag powder 2 parts, polyvinylpyrrolidone 1.1 parts. The solution B includes the following raw materials in parts by weight: 98.0 parts of water, 2 parts of KH570 type silane coupling agent, cuprous oxide modified graphene oxide (GO-Cu 2 O) 0.15 parts, wherein; the GO-Cu 2 The loading amount of cuprous oxide in O is 4% (mol fraction), promptly adds 4mol cuprous oxide in every 100mol graphene oxide. The humidity regulator includes the following raw materials in parts by weight: 50 parts of zeolite, 20 parts of diatomite, 3 parts of sodium bentonite, and 0.6 part of water-absorbing resin.

[0066] The fly ash is...

Embodiment 3

[0075] A method for preparing a humidity-adjustable cement ceiling board, comprising the following raw materials: material A, solution B, a humidity regulator and polypropylene fiber mesh cloth; wherein: the material A includes the following raw materials in parts by weight: 42.5 silicic acid 40 parts of salt cement, 40 parts of fly ash, 5 parts of papermaking sludge ash, 10 parts of ultrafine slag powder, and 0.3 parts of polyvinylpyrrolidone. The solution B includes the following raw materials in parts by weight: 97.95 parts of water, 1 part of KH570 type silane coupling agent, cuprous oxide modified graphene oxide (GO-Cu 2 O) 0.05 part, wherein; the GO-Cu 2 The loading amount of cuprous oxide in O is 3% (mol fraction), promptly adds 3mol cuprous oxide in every 100mol graphene oxide. The humidity regulator includes the following raw materials in parts by weight: 75 parts of zeolite, 10 parts of diatomite, 9 parts of sodium bentonite, and 0.2 part of water-absorbing resin. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com