Ionic liquid lubricant for titanium alloy and preparation method and applications thereof

A technology for ionic liquids and lubricants, applied in the direction of sulfonate preparation, lubricating compositions, chemical instruments and methods, etc., can solve problems such as unsatisfactory and unsatisfactory lubricating performance, achieve excellent anti-wear and anti-friction performance, and improve friction The effect of academic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

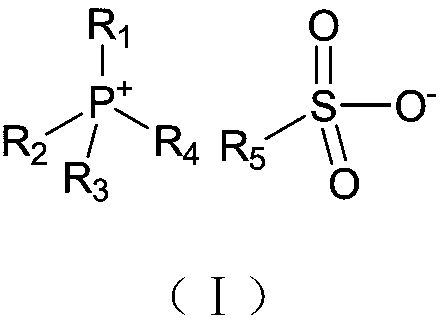

[0026] Embodiment 1: Ionic liquid lubricant C 6 f 13 SO 3 P 4444 preparation of

[0027] Potassium perfluorohexylsulfonate and tetra-n-butylphosphine bromide with a molar ratio of 1:1 were dissolved in acetone and reacted at room temperature for 24 hours. After the reaction was completed, the solid precipitate was removed by filtration and extracted with ethyl acetate. The organic phase is washed 3 times with equal volumes of water, and the solvent is evaporated to obtain the final product (A). 6 f 13 SO 3 P 4444 express.

[0028] The final product (A)C was characterized using NMR spectroscopy 6 f 13 SO 3 P 4444 : 1 HNMR (400MHz, CDCl3) δ (ppm): 0.90 (t, J = 7.1Hz, 1H), 1.58–1.35 (m, 16H), 2.26–2.03 (m, 8H), 13 C NMR (100MHz, CDCl3) δ (ppm): 23.88, 23.73, 23.59, 23.54, 18.75, 18.28.

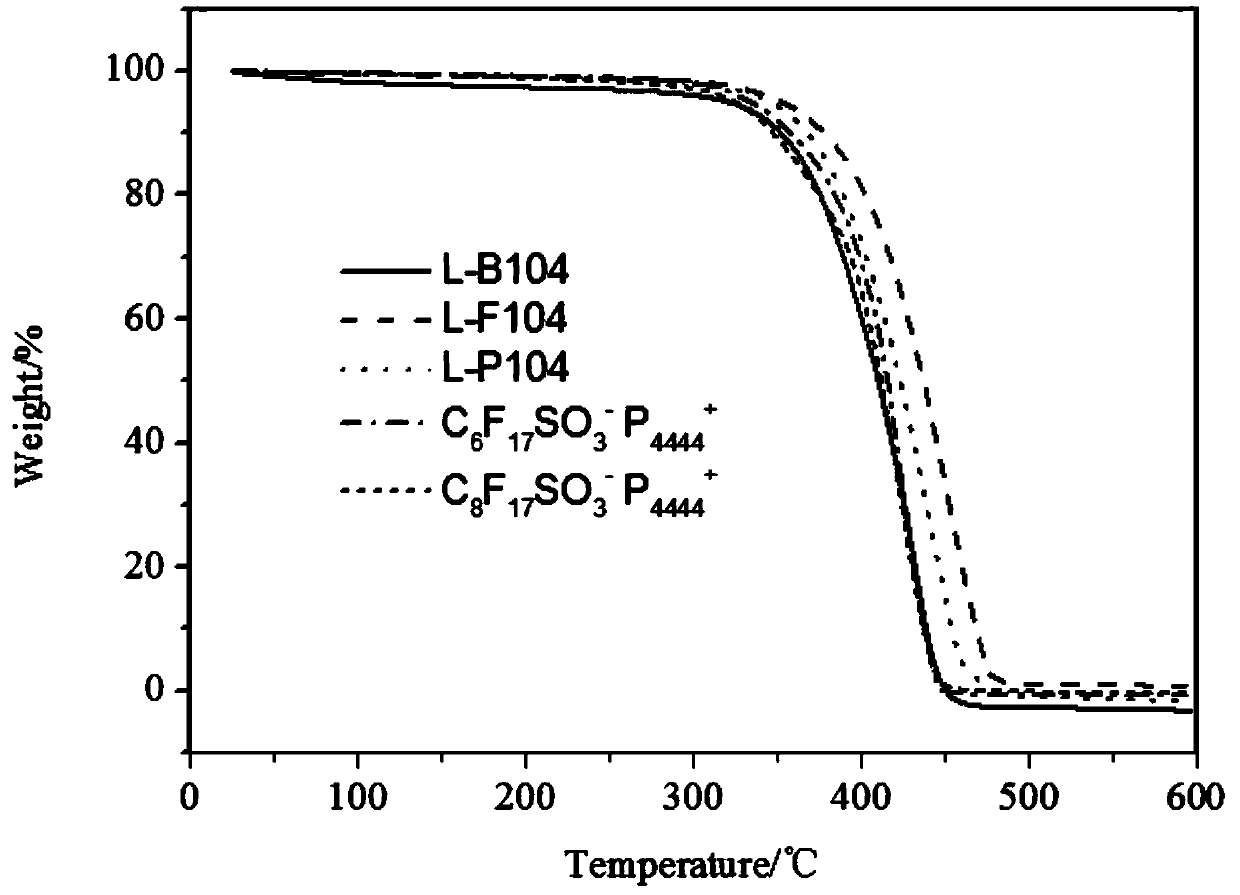

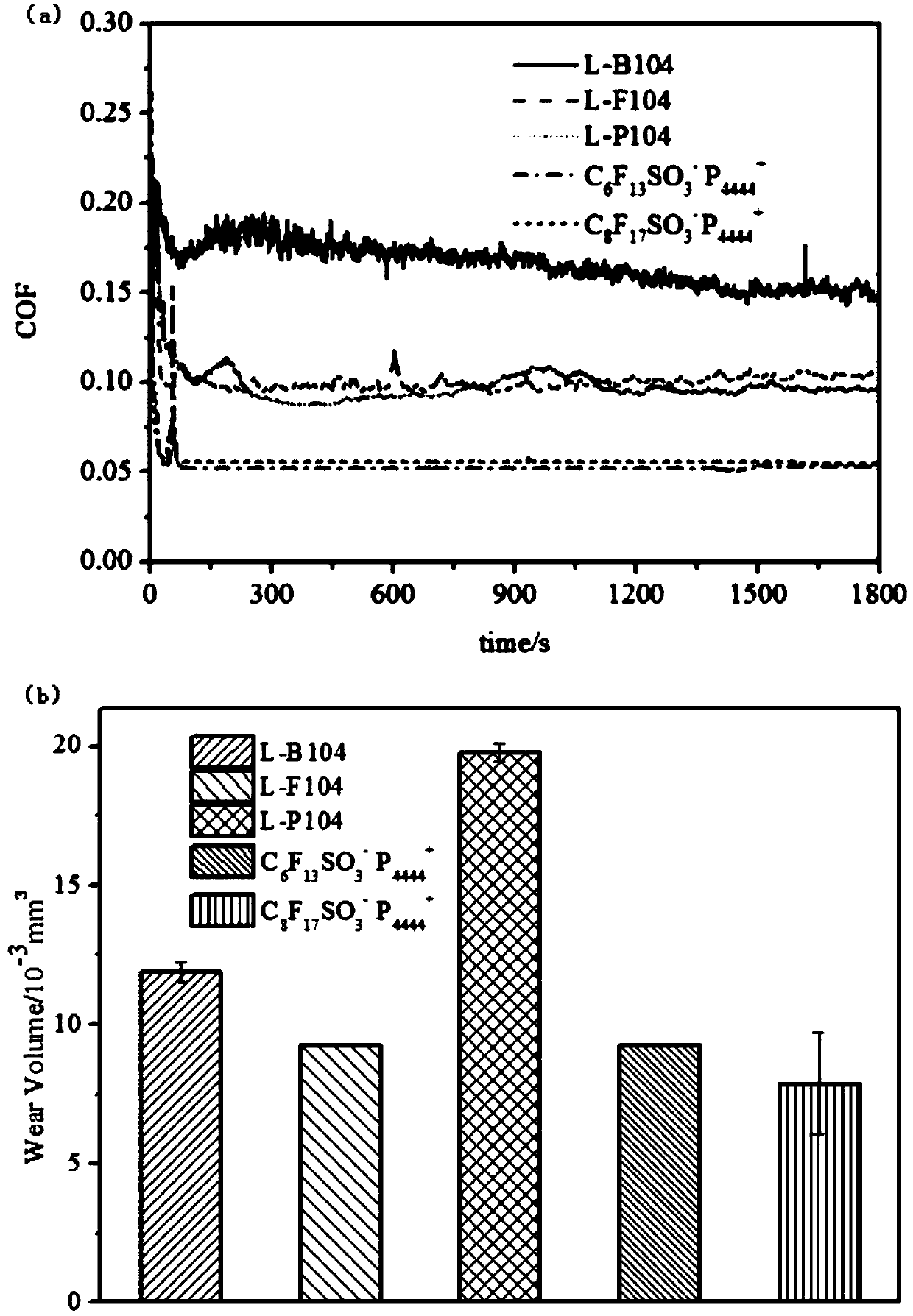

[0029]The friction and wear properties of the ionic liquid lubricant (A) were evaluated, and compared with the traditional ionic liquids L-F104, L-P104, and L-B104. The average fri...

Embodiment 2

[0030] Embodiment 2: Ionic liquid lubricant C 8 f 17 SO 3 P 4444 preparation of

[0031] Dissolve potassium perfluorooctane sulfonate and tetra-n-butylphosphine bromide in acetone with a molar ratio of 1:1, and react at room temperature for 24 hours. After the reaction, remove the solid precipitate by filtration and extract with ethyl acetate , the organic phase was washed 3 times with equal volumes of water, and the solvent was evaporated to obtain the final product (B), which was obtained by the simplified formula C 8 f 17 SO 3 P 4444 express.

[0032] The final product (B)C was characterized using NMR spectroscopy 8 f 17 SO 3 P 4444 : 1 H NMR (400MHz, CDCl3) δ (ppm): 0.91 (t, J = 7.1Hz, 12H), 1.46 (dt, J = 7.4, 3.8Hz, 16H), 2.25–2.06 (m, 8H), 13 C NMR (100MHz, CDCl 3 )δ (ppm): 23.89, 23.74, 23.61, 23.56, 18.78, 18.31, 13.20.

[0033] The friction and wear properties of the ionic liquid lubricant (B) were evaluated, and compared with the traditional ionic liqu...

Embodiment 3

[0034] Embodiment 3: Ionic liquid lubricant C 8 f 17 SO 3 P 8888 preparation of

[0035] Dissolve potassium perfluorooctane sulfonate and tetra-n-octylphosphine bromide in acetone at a molar ratio of 1:1, and react at room temperature for 24 hours. After the reaction, remove the solid precipitate by filtration and extract with ethyl acetate , the organic phase was washed 3 times with equal volumes of water, and the solvent was evaporated to obtain the final product (C). 8 f 17 SO 3 P 8888 express.

[0036] The final product (C)C was characterized using NMR spectroscopy 8 f 17 SO 3 P 8888 : 1 H NMR (400MHz, CDCl 3 )δ (ppm): 0.85 (dd, J = 7.5, 12H), 1.24 (s, 32H), 1.59–1.37 (m, 16H), 2.36–2.12 (m, 8H), 13 C NMR (100MHz, CDCl 3 )δ (ppm): 31.76, 30.87, 30.73, 29.03, 28.96, 22.65, 21.91, 21.86, 19.34, 18.87, 14.06.

[0037] Evaluate the friction and wear performance of the ionic liquid lubricant (C), and compare it with traditional ionic liquids L-F104, L-P104, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com