High quality sintered ores for COREX smelting reduction process for ironmaking and preparation method thereof

A sintering, high-quality technology, applied in the field of iron and steel metallurgy, to achieve the effect of increasing vertical sintering speed and utilization factor, improving air permeability, and overcoming poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

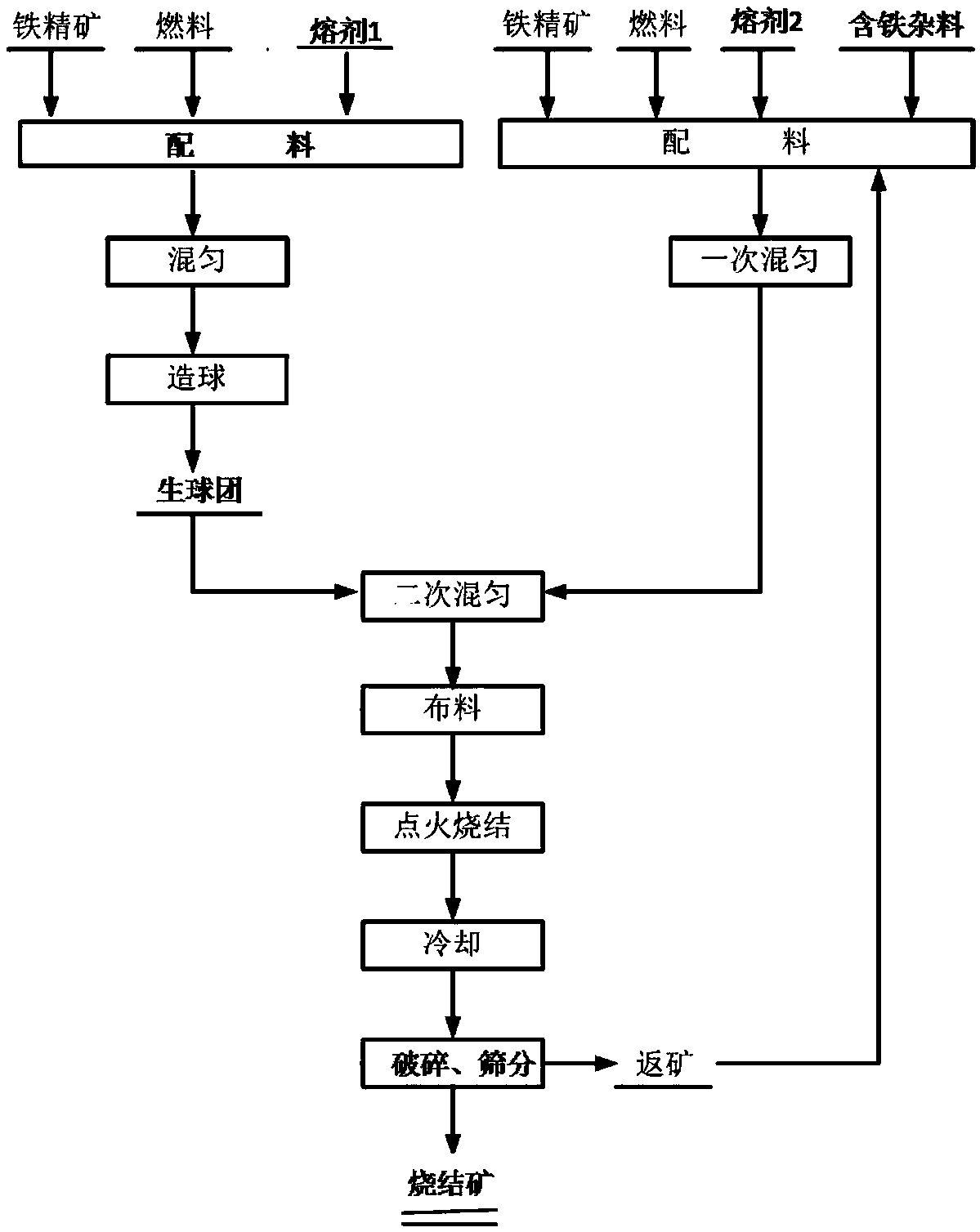

Method used

Image

Examples

Embodiment 1

[0040] According to the requirement of 50% mass percentage of sintered ore in the subsequent smelting, the designed sinter basicity is 1.8 and the MgO content is 1.6%. Divide 30% of the iron concentrate in the total amount of iron concentrate, add finely ground quicklime, 4% dolomite and 1.4% solid fuel (coke powder), which account for 2.5% of the concentrated iron ore obtained by the diversion, for batching and mixing. Homogenize to obtain a mixture 1, wherein the iron concentrate particle size is -0.074mm>40%, and the iron element content is greater than 62.5%. Mixture 1 is made into raw balls of 8mm-20mm directly in a disc ball machine, and the raw ball alkalinity (CaO and SiO) 2 The mass percentage ratio) is 1.0, the MgO content is 1.8%, and the solid fuel mass ratio is 1.4%.

[0041] 70% of the iron concentrate and iron-containing impurities (including iron-containing dust and iron-containing pellets in steel mills) in the total iron concentrate are combined with returne...

Embodiment 2

[0046] According to the requirement of 50% mass percentage of sintered ore in the subsequent smelting, the designed sinter basicity is 1.8 and the MgO content is 1.6%. Divide 50% of the iron concentrate in the total amount of iron concentrate, add finely ground quicklime, 3.5% dolomite and 1.2% solid fuel (anthracite powder) accounting for 3% of the concentrated iron ore obtained by the diversion to it for batching and mixing. Homogenize to obtain a mixture 1, wherein the iron concentrate particle size is -0.074mm>40%, and the iron element content is greater than 62.5%. The mixture is directly 8mm-20 formed by a disc pelletizing machine, the green ball basicity is 1.2, the MgO content is 1.7%, and the solid fuel mass ratio is 1.2%.

[0047] 50% of the iron concentrate and iron-containing miscellaneous materials (including iron-containing dust and iron-containing pellets in steel mills) in the total iron concentrate are combined with returned ore, quicklime, limestone, dolomite...

Embodiment 3

[0053] According to the requirement of 50% mass percentage of sintered ore in the subsequent smelting, the designed sinter basicity is 1.8 and the MgO content is 1.6%. Divide 60% of the iron concentrate in the total amount of iron concentrate, add finely ground quicklime, 2.5% magnesite and 1.4% solid fuel (coke powder), which account for 2% of the concentrate obtained by the diversion, for batching and mixing. Homogenize to obtain a mixture 1, wherein the iron concentrate particle size is -0.074mm>40%, and the iron element content is greater than 62.5%. The mixture is directly formed into 8mm-20mm green pellets in a disc pelletizing machine, the alkalinity of the pellets is 0.8, the MgO content is 1.0%, and the solid fuel mass ratio is 1.4%.

[0054] 40% of the iron concentrate and iron-containing miscellaneous materials (including iron-containing dust in steel mills, iron-containing pellets and iron-containing nugget sifting) in the total iron concentrate are mixed with retu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com