Natural silk micro-nano-fiber preparation method

A technology of micro-nano fiber and natural silk, which is applied in the direction of spinning solution preparation, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of limited application prospects, difficulty in mechanical crushing, and limited diameter adjustment of silk fibroin nanofibers. Reduce mechanical force and time, reduce excessive decomposition and waste, and can adjust a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

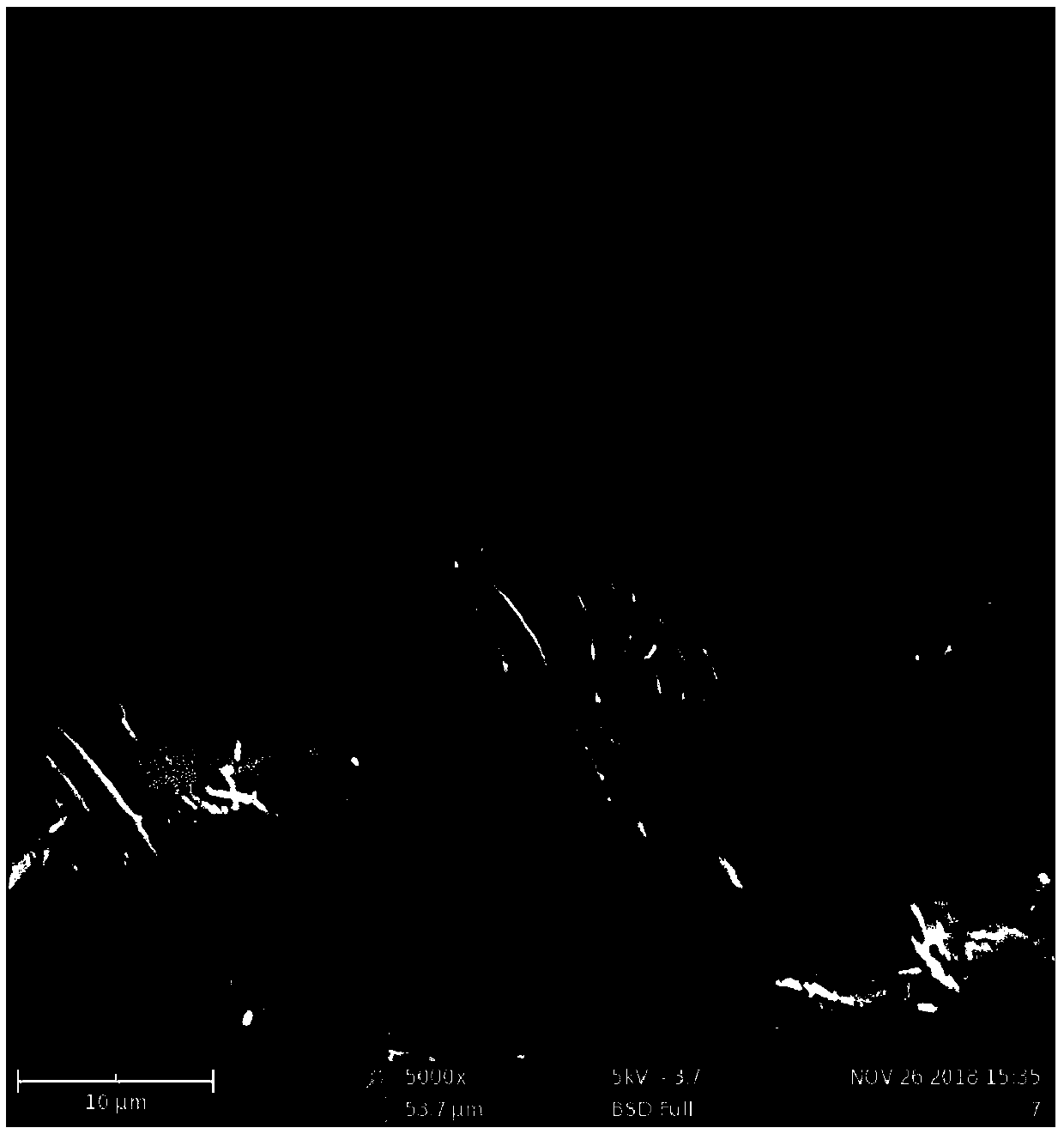

[0029] A kind of preparation method of natural silk micro-nano fiber of the present embodiment, described method comprises the steps:

[0030] (1) Immerse silkworm raw silk into 0.6% NaCO 3 In the solution, boil at 98-100°C for 30 minutes, repeat 3 times, pretreat the silk, remove sericin and weaken the force between silk fibrils, and then fully wash and dry the degummed silk Obtain pure silk fiber;

[0031] (2) Shred the pure silk fiber obtained in step (1) to a length of 0.1-10 cm, and then add it to a ternary mixed solution composed of calcium nitrate / ethanol / deionized water to obtain a dispersed silk fiber-containing liquid, wherein: the mass volume concentration of calcium nitrate in the ternary mixed solution is 2g / ml, and the volume ratio of the deionized water to ethanol is 2:1;

[0032] (3) subjecting the dispersion liquid containing silk fibers obtained in step (2) to mechanical stirring at 45° C. for 2 hours to obtain silk micro-nano fiber slurry;

[0033] (4) Th...

Embodiment 2

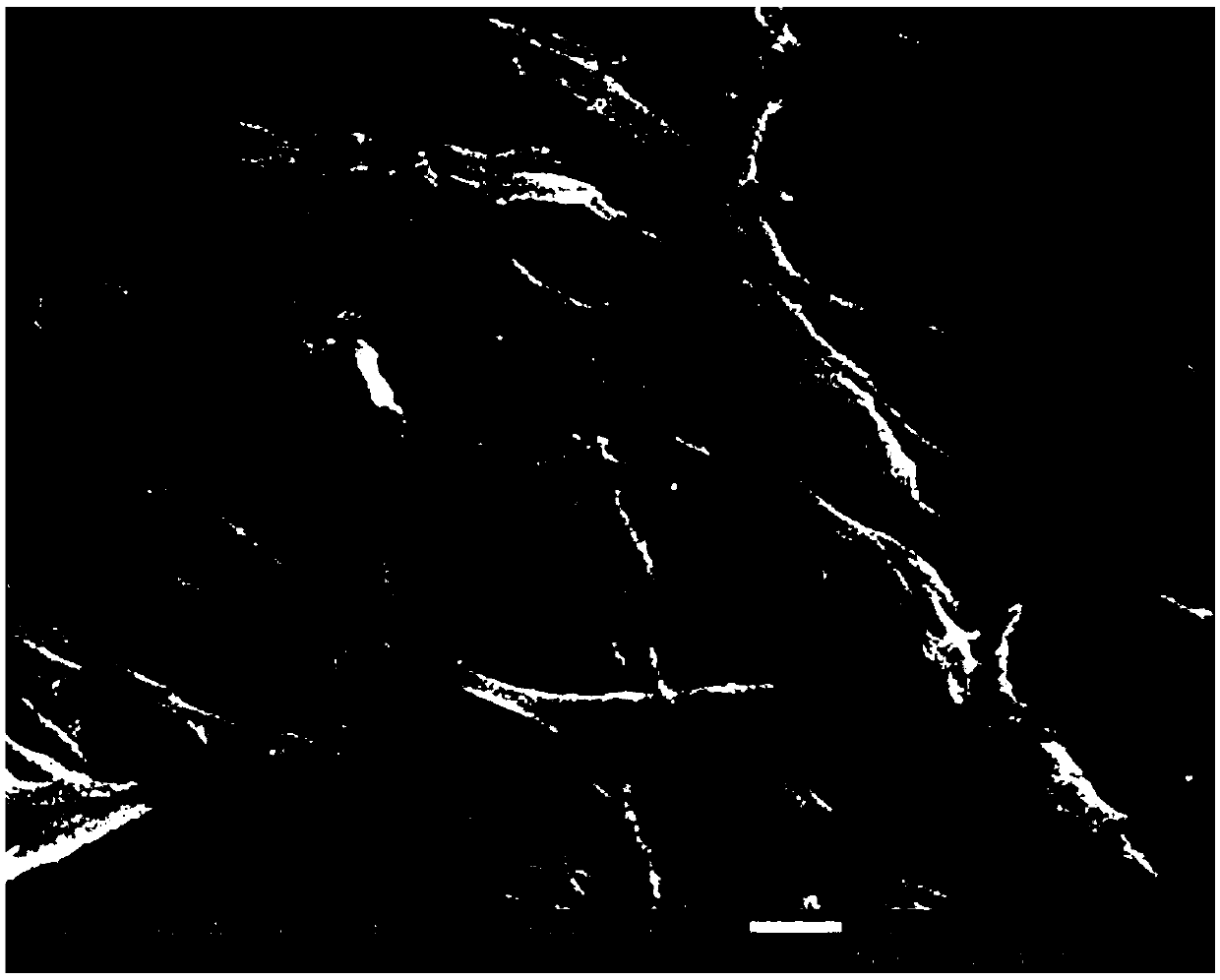

[0036] A kind of preparation method of natural silk micro-nano fiber of the present embodiment, described method comprises the steps:

[0037] (1) Immerse silkworm raw silk into 1.0% NaCO 3 In the solution, boil at 98-100°C for 30 minutes, repeat 3 times, pretreat the silk, remove sericin and weaken the force between silk fibrils, and then fully wash and dry the degummed silk Obtain pure silk fiber;

[0038] (2) Shred the pure silk fiber obtained in step (1) to a length of 0.1 to 10 cm, and then add it to a ternary mixed solution composed of calcium nitrate / butanol / deionized water to obtain silk fiber-containing Dispersion liquid, wherein: the mass volume concentration of calcium nitrate in the ternary mixed liquid is 5 g / ml, and the volume ratio of deionized water to butanol is 3:1;

[0039] (3) Dispersing the silk fiber-containing dispersion liquid obtained in step (2) under the condition of 50° C., mechanically agitating and loosening for 4 hours to obtain silk micro-nano f...

Embodiment 3

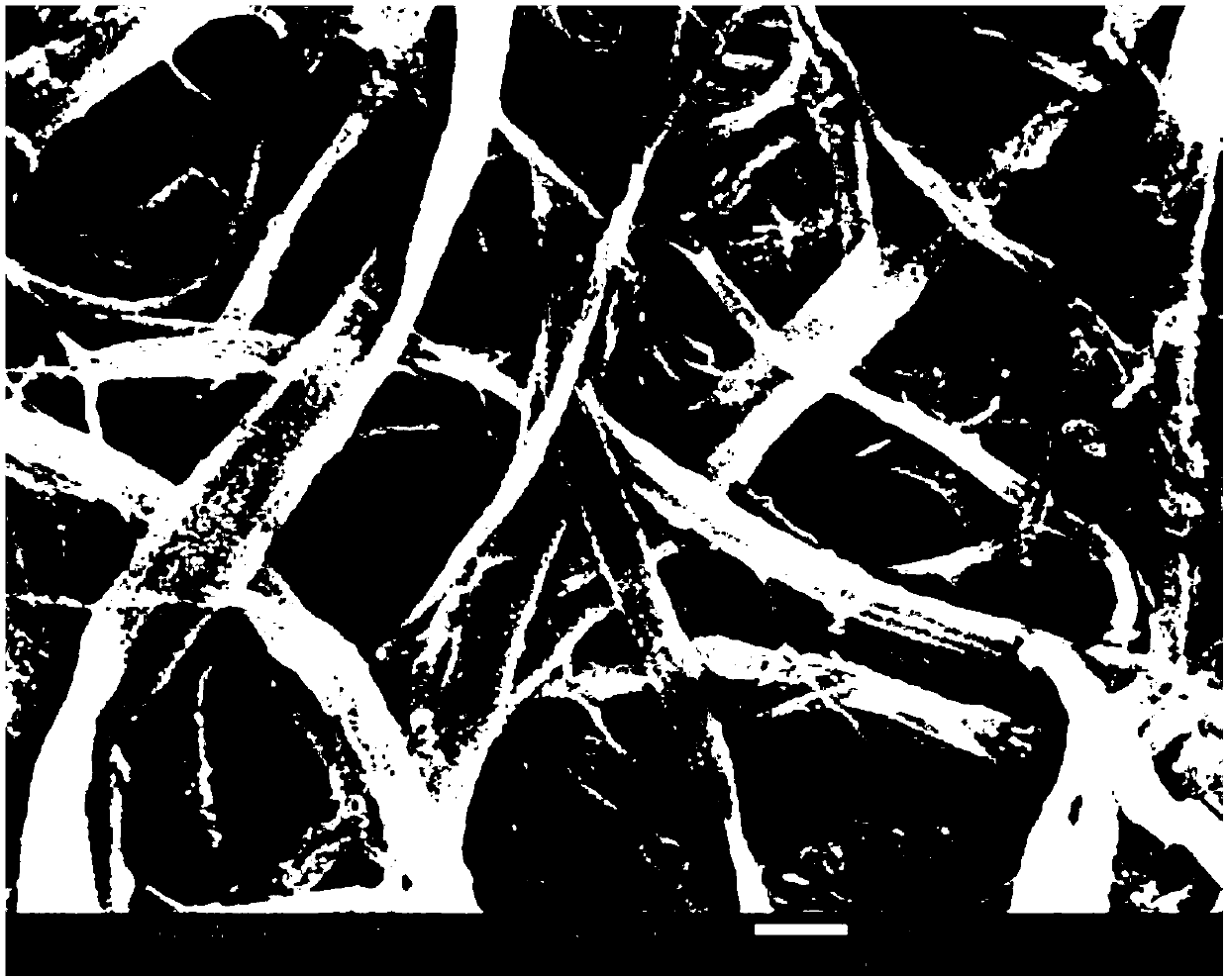

[0043] A kind of preparation method of natural silk micro-nano fiber of the present embodiment, described method comprises the steps:

[0044] (1) Immerse silkworm raw silk into NaCO with a mass fraction of 2.0% 3 In the solution, boil at 98-100°C for 30 minutes, repeat 3 times, pretreat the silk, remove sericin and weaken the force between silk fibrils, and then fully wash and dry the degummed silk Obtain pure silk fiber;

[0045] (2) Shred the pure silk fiber obtained in step (1) to a length of 0.1 to 10 cm, and then add it to a ternary mixed solution composed of calcium nitrate / propanol / deionized water to obtain silk fiber-containing Dispersion liquid, wherein: the mass volume concentration of calcium nitrate in the ternary mixed liquid is 4g / ml, and the volume ratio of deionized water to propanol is 4:1;

[0046] (3) Dissolving the silk fiber-containing dispersion liquid obtained in step (2) under the condition of 60° C. for 3 hours with mechanical stirring to obtain sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com