Heat preservation and insulation board, preparation method thereof and application of board

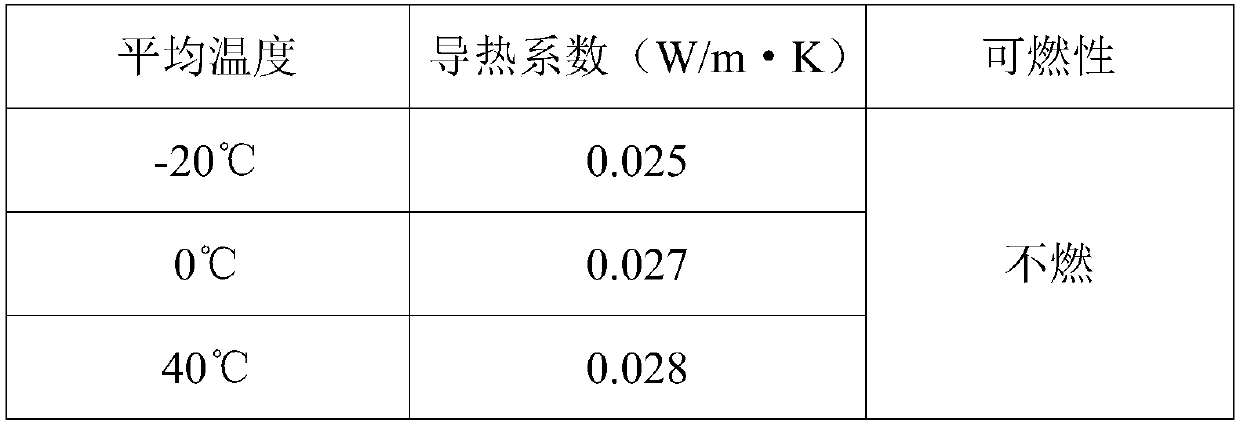

A technology for thermal insulation boards and raw materials, which is applied in thermal insulation, chemical instruments and methods, climate change adaptation, etc. problem, to achieve the effect of uniform thermal insulation, good thermal insulation, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

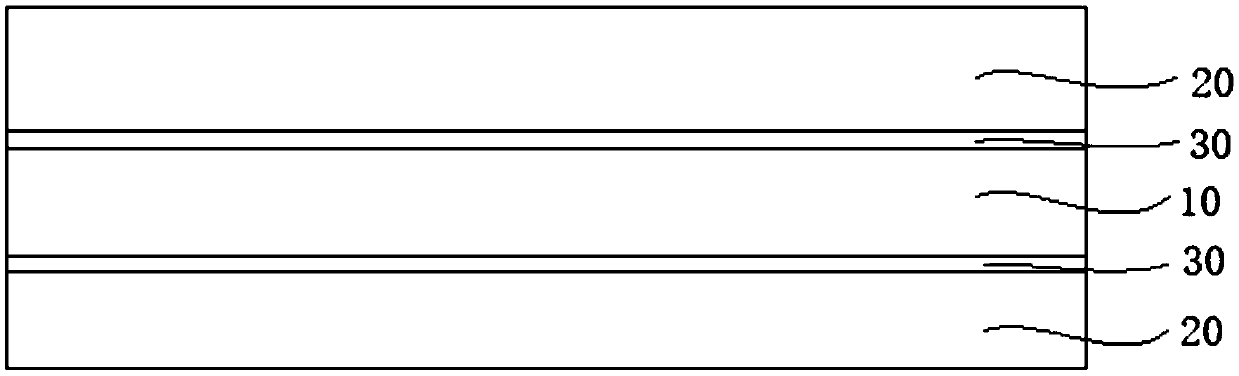

Image

Examples

preparation example Construction

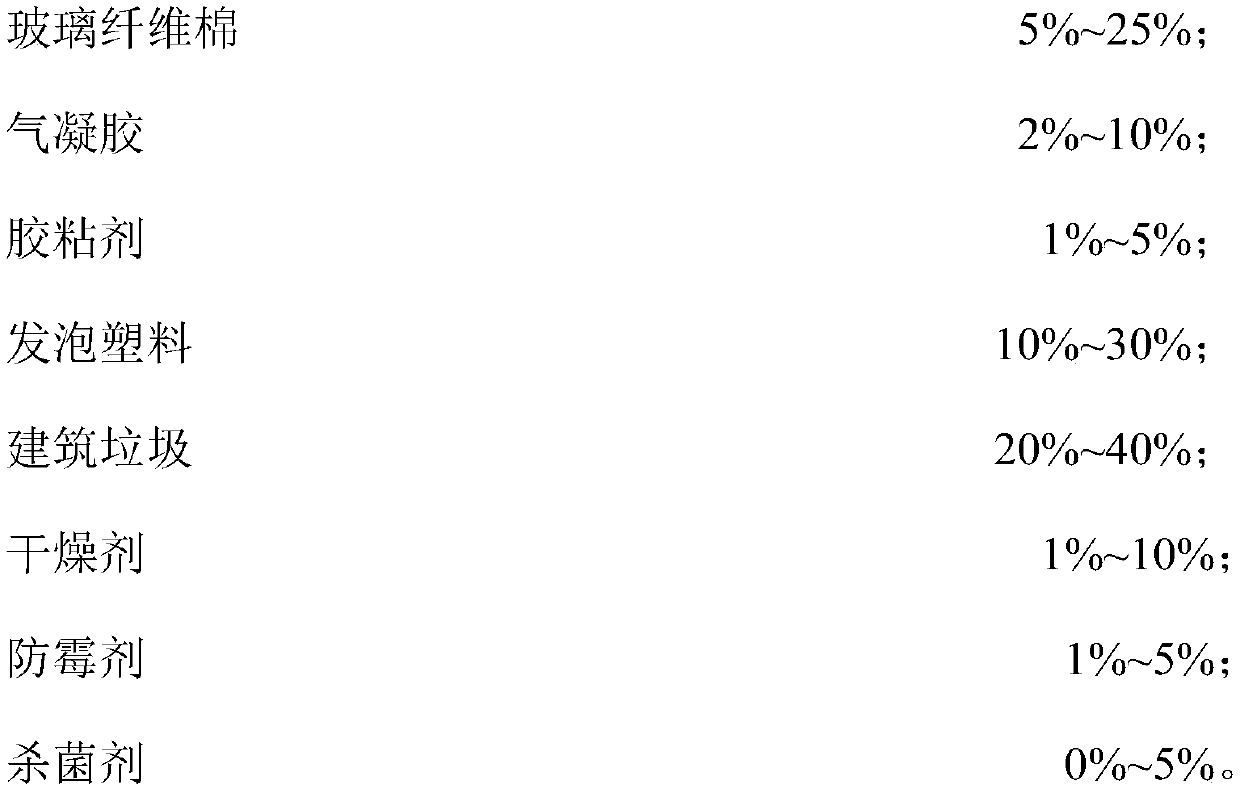

[0041] A method for preparing a thermal insulation board in an embodiment includes the following steps S110-S160:

[0042] S110 , laying surface layer raw materials to form a first surface layer.

[0043] Among them, the surface layer raw materials include glass fiber cotton and airgel.

[0044] It can be understood that glass fiber wool is an inorganic non-metallic material with excellent performance. It has a wide variety and has good insulation, heat resistance, corrosion resistance and mechanical strength. Airgel is a form of solid matter with extremely low density. Since more than 80% of airgel is air, it has a very good heat insulation effect. One inch thick airgel is equivalent to 20 to 30 pieces of ordinary glass. Thermal insulation function. Therefore, using glass fiber wool and aerogel as surface layer raw materials can take advantage of the loose structure of glass fiber wool to adsorb airgel in the pores of glass fiber wool, greatly improving the toughness and st...

Embodiment 1

[0068] (1) Pretreatment of construction waste: take out the steel bars in the construction waste, sort and crush the construction waste after drying, sieve with a 0.4mm sieve hole, and take the under-sieve as the production raw material for subsequent use;

[0069] (2) Pretreatment of glass fiber cotton: dry glass fiber cotton, remove harmful substances and impurities, and set aside;

[0070] (3) Preparation of surface layer raw materials: mix the pretreated glass fiber cotton and airgel evenly for standby; mix the desiccant, bactericide and mildewproof agent evenly for standby;

[0071] (4) Preparation of raw materials for the middle layer: mix the foamed plastic particles and the pretreated construction waste in a ratio of 1:2, and set aside;

[0072] (5) Lay the mixture of glass fiber cotton and airgel obtained in step (3) evenly in the die, and the thickness is determined according to the thickness of the wall or roof hollow layer of the prefabricated building with thin-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com