Composite positive electrode material, preparation method thereof and lithium air battery

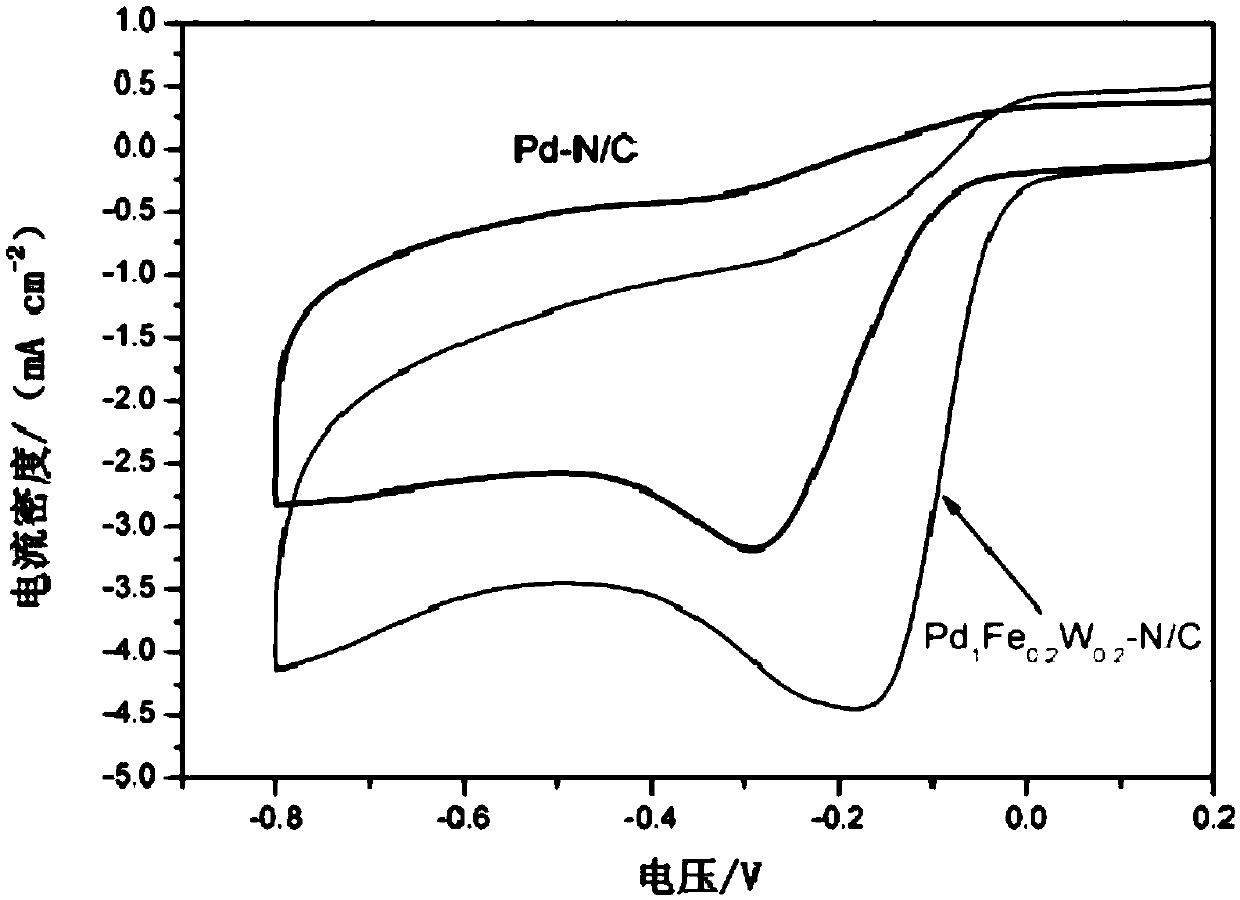

A technology of composite cathode material and carbonized material, applied in the field of lithium-air battery, can solve the problems of poor catalytic activity and poor cycle stability, and achieve the effect of improving catalytic effect, strong stability and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

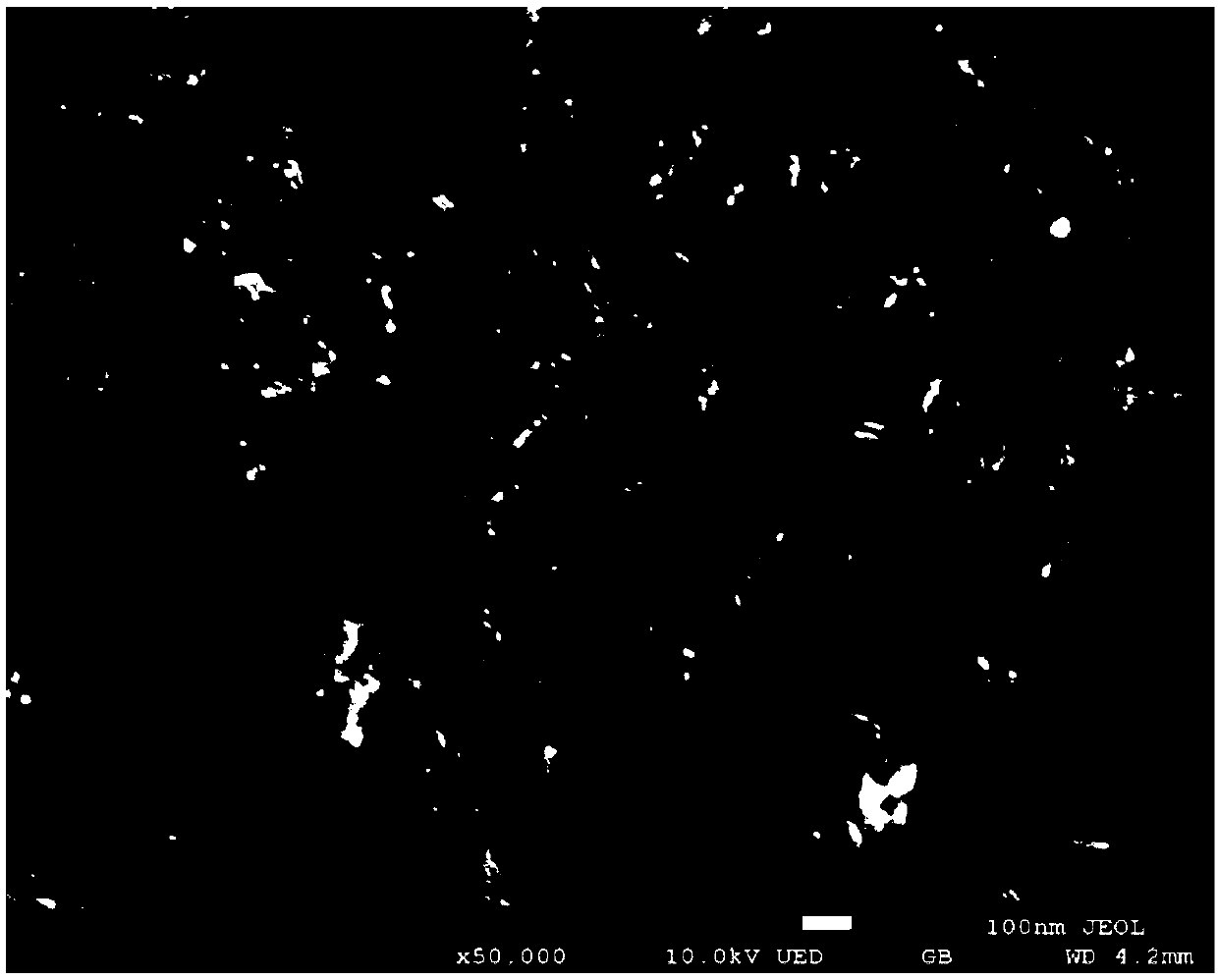

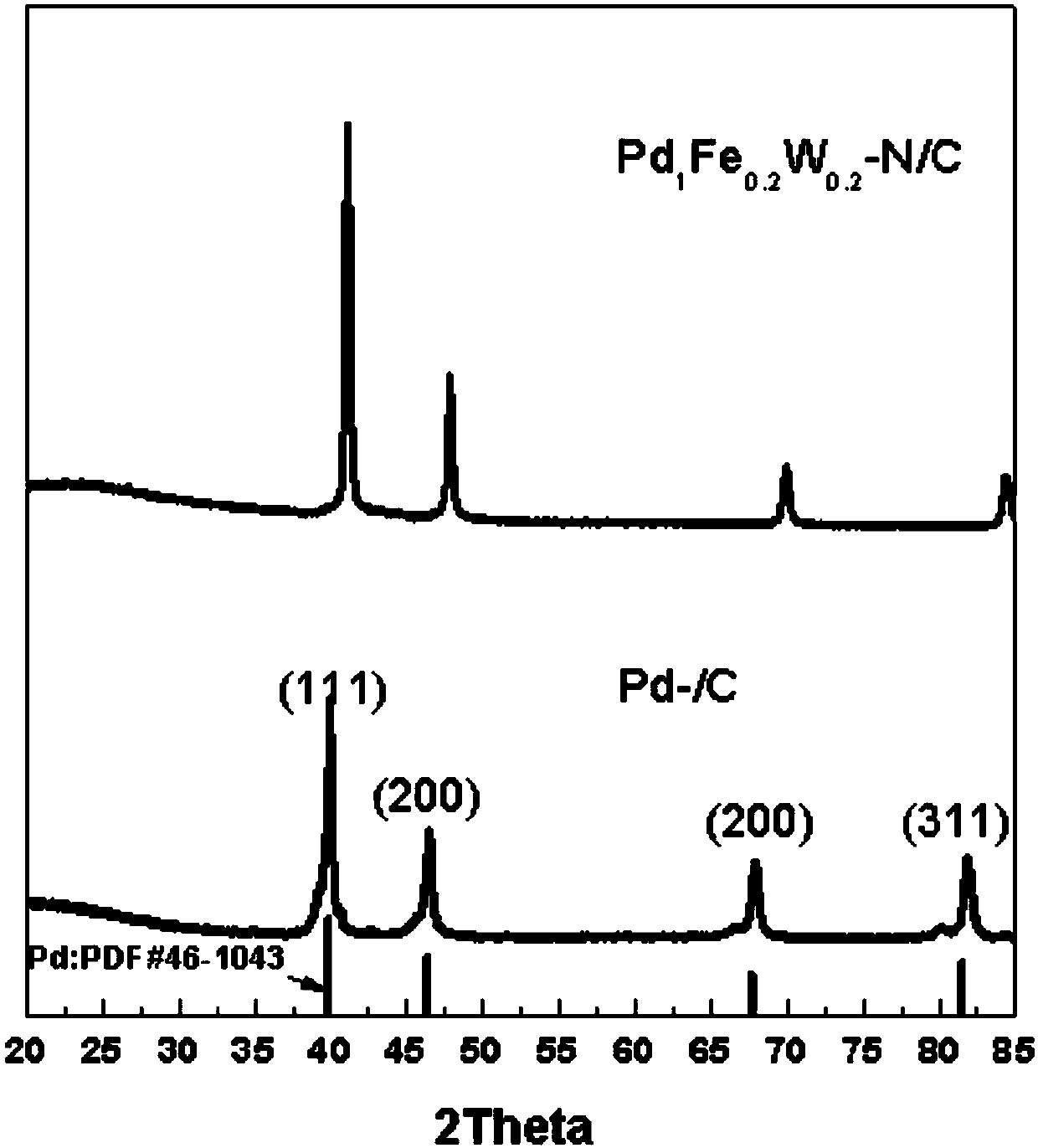

[0038] The embodiment of the present invention provides a method for preparing a composite positive electrode material, the composite positive electrode material is nitrogen-doped porous carbon supported Pd x Fe y W z Nano alloy, and the preparation method of the composite cathode material comprises the following steps:

[0039] S01. Provide an aqueous solution of lignin salt and an anhydrous alcohol solution of polyacrylonitrile, and mix the aqueous solution of lignin salt and the anhydrous alcohol solution of polyacrylonitrile to form a first mixed solution;

[0040] S02. Provide nano-silica powder, disperse the nano-silica powder in the first mixed solution to obtain a second mixed solution, and perform a programmed heat treatment on the second mixed solution to prepare a carbonized material Adding an etching solution to the carbonized material, etching and removing the silicon dioxide in the carbonized material, and preparing nitrogen-doped porous carbon; wherein, the pr...

Embodiment 1

[0089] A method for preparing a composite cathode material, comprising the following steps:

[0090] (1) Using tetraethyl orthosilicate as the silicon source and hexadecyltrimethylammonium bromide as the template, the traditional sol-gel and homogeneous precipitation method was used to prepare a compound with a particle size concentrated in the alkaline aqueous solution. 150-200nm SiO 2 ball.

[0091] (2) Sodium lignosulfonate is dissolved in water, stirred to form a uniform solution A, the solid content of the solution is 20%; polyacrylonitrile powder is dissolved and dispersed in dehydrated alcohol, stirred to form a uniform solution B, the solid content of the solution The content is 20%. Mix solutions A and B uniformly at a volume ratio of 10:1 to form mixed solution C.

[0092] (3) Preparation of nitrogen-doped porous carbon N / C. Take an appropriate amount of SiO in step (1) 2 Put it into a 50mL corundum porcelain boat, then take an appropriate amount of solution C i...

Embodiment 2

[0095] A method for preparing a composite cathode material, comprising the following steps:

[0096] (1) Using tetraethyl orthosilicate as the silicon source and hexadecyltrimethylammonium bromide as the template, the traditional sol-gel and homogeneous precipitation method was used to prepare a compound with a particle size concentrated in the alkaline aqueous solution. 150-200nm SiO 2 ball.

[0097] (2) Sodium lignosulfonate is dissolved in water, stirred to form a uniform solution A, the solid content of the solution is 10%; polyacrylonitrile powder is dissolved and dispersed in dehydrated alcohol, stirred to form a uniform solution B, the solid content of the solution The content is 10%. Mix solutions A and B uniformly at a volume ratio of 10:2 to form mixed solution C.

[0098] (3) Preparation of nitrogen-doped porous carbon N / C. Take an appropriate amount of SiO in step (1) 2 Put it into a 50ML corundum porcelain boat, then take an appropriate amount of solution C i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com