Method for clean and stable storage of cyanohydrin products

A technology of cyanohydrin and products, which is applied in the field of clean and stable storage of cyanohydrin products, can solve the problems of undifferentiated storage time and waste of resources, and achieve the effects of reducing the impact of impurities, saving resources, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

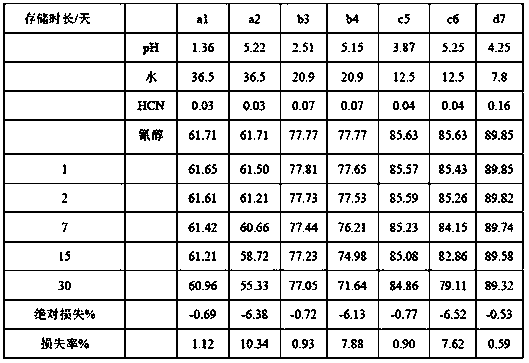

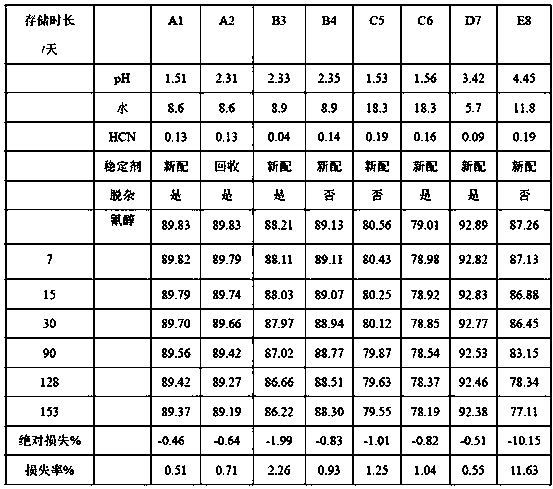

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 catalyst

[0045] Take 3.5Kg H-type carboxylic acid-based domestically produced D113 macroporous ion exchange resin (if it is Na-type resin, it needs to be soaked in dilute acid solution to convert to hydrogen-type), rinse with a small amount of water to remove possible soluble impurities, add 2 Double the volume of industrial desalted water and swell for 30~60min. After swelling, remove floating mechanical impurities or broken resin, pour out excess water until the resin is just wet, and adjust to pH=4 with 2~10% sodium hydroxide or potassium hydroxide solution ~7 and keep it for 10~40min, then transfer the prepared catalyst directly into the packed tower or keep it moist and sealed for later use.

Embodiment 2

[0046] Embodiment 2 raw material pretreatment

[0047] The crude hydrogen cyanide gas from the hydrogen cyanide synthesis workshop is processed by two-stage absorption and deamination with 10~98% sulfuric acid, and the composition of crude hydrogen cyanide gas is as follows: hydrogen cyanide gas 9.4%±2%, hydrogen gas 1.6%± 1%, nitrogen 79.4%±2%, oxygen 1.7%±1%, carbon monoxide 5.8%±2%, carbon dioxide 1.5%±1%, methane 0.6%±0.5%, water vapor 3.7%±2%;

[0048] The 3-methylthiopropanal raw material from the 3-methylthiopropanal (MMP) synthesis unit is mixed with 5-8% water by mass in a static mixer to obtain a water-dispersed emulsion;

Embodiment 3

[0049] Example 3 Synthesis of 2-hydroxyl-4-methylthiobutyronitrile for the first time

[0050] Turn on the heat exchanger of the packed tower, and control the temperature inside the tower at 25-80° C. The tower is loaded with the carboxylic acid-based polymer resin buffer salt catalyst prepared in Example 1.

[0051] The crude hydrogen cyanide gas from the deammonization Angle method of embodiment 2 enters from the bottom of the packed tower, and the gas velocity is 2 ~ 15L / min; The top enters, the flow rate is 1~10L / min, the two react countercurrently in the packed tower, and the crude cyanohydrin containing 1~8% MMP is obtained at the bottom of the reaction tower, and the crude cyanohydrin is pumped to the top of the tower by the circulating pump at the bottom of the packed tower At the circulation port, the whole tower is circulated to continue the reaction until MMP is completely converted into cyanohydrin (MMP residue is less than 0.5%).

[0052] After the initial feed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com