Energy absorbing method based on dynamic cross-linking polymer

A dynamic cross-linking, polymer technology, applied in the field of energy absorption, can solve the problems of impact energy dissipation, human injury, limited shock absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0174] In the preparation process of dynamic polymer foam materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0175] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0176] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under press...

Embodiment 1

[0222] Add 200ml of toluene solvent into a dry and clean reaction bottle, and then add 8g of styrene and 1.26g of 1,3,5-triacryloylhexahydro-1,3,5-triazine after passing argon to remove water and oxygen for 1 hour (a), 1.2wt% benzoyl peroxide was heated to 80°C under the protection of argon for 5h to form a cross-linked network, and then the product was placed in a suitable mold and dried in a vacuum oven at 80°C for 24h to finally obtain a hard A translucent polymer solid with a smooth surface, a certain degree of gloss and surface hardness. In this embodiment, the obtained polymer solid can be used as an anti-shock protection material, such as the housing of home appliances, telephone housings, instruments and meters, etc., to protect and buffer the articles. When cracks appear on the surface, it can The samples were impregnated with hydrochloric acid aqueous solution and heated at 130°C to realize the self-healing of cracks.

[0223]

Embodiment 2

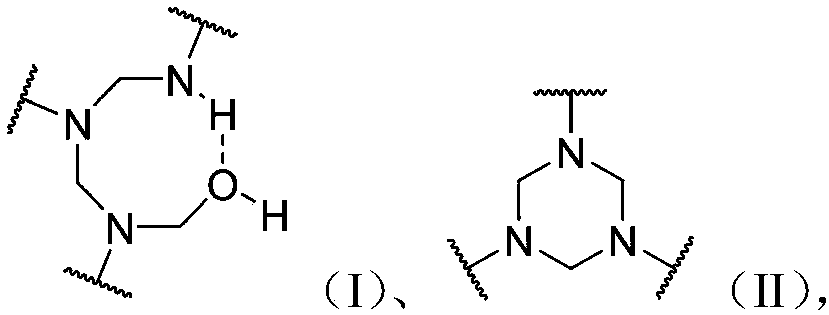

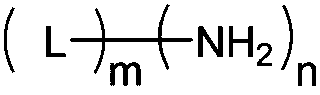

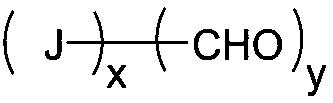

[0225] Using AIBN as the initiator and triethylamine as the catalyst, it is prepared by thiol-ene click reaction with equimolar amounts of 1,4-butenediol and N-[(2-mercaptoethyl)carbamoyl]propionamide Hydroxyl double-terminated compound; DCC and DMAP are used as condensation reagents to obtain olefin double-terminated compound through esterification with acrylic acid; then AIBN is used as initiator and triethylamine as catalyst, and 2-amino Amino compound (a) was prepared from ethanethiol by thiol-ene click addition reaction.

[0226] Add 20g of aldehyde-terminated polyethylene glycol 2,000, 3g of amino compound (a), 1.62g of trimesaldehyde, and 0.2mg of antioxidant BHT into a dry and clean three-necked flask, heat to 50°C for stirring reaction, and react for 2 hours , cooled to room temperature, a light yellow transparent viscous sample can be obtained, which has good resilience and can be used as a protective coating to coat the surface of the substrate to protect the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stretching rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com