Chrysanthemum-like light calcium carbonate filler preparation method

A light calcium carbonate and chrysanthemum technology is applied in fiber raw material processing, textiles and papermaking, papermaking and other directions, which can solve the problems of long limestone calcination time, complicated process and high production cost, and achieves reduction of papermaking cost, simple process and improved retention. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

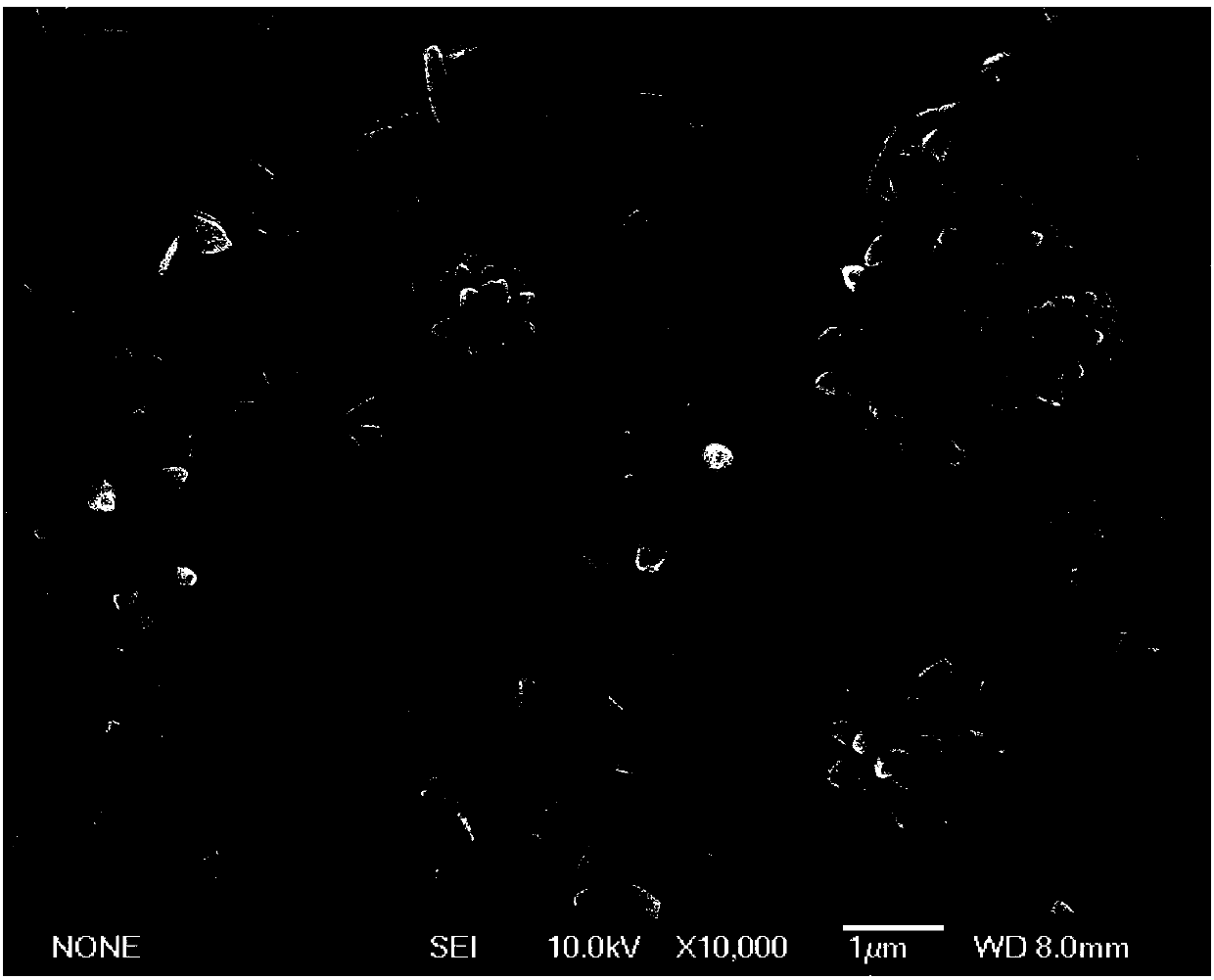

Embodiment 1

[0033] The automatic mechanical vertical steel kiln is adopted, the limestone with a size of 30-60mm is selected, the coal-stone ratio is 80kg / T limestone, the calcination temperature is controlled between 1000°C, and the calcination time is 25h. Lime is digested in hot water at 80°C, and the mass ratio of lime to water is 1:6. Add water to the digested coarse pulp to adjust the concentration to 15%, first pass through a 100-mesh sieve, and then pass through a hydrocyclone to remove impurities to obtain a fine pulp. After the seminal pulp was aged for 24 hours, the temperature was lowered to 45°C. Pour the fine slurry into a carbonization tower, add 1‰ citric acid (dry relative to PCC) (concentration: 30%) as a crystal form control agent, and stir evenly. Ventilate for carbonization, the kiln gas concentration is 30%, and continuously detect the conductivity online during the carbonization process. When the conductivity reaches the minimum and then increases by 0.5mS / cm, stop...

Embodiment 2

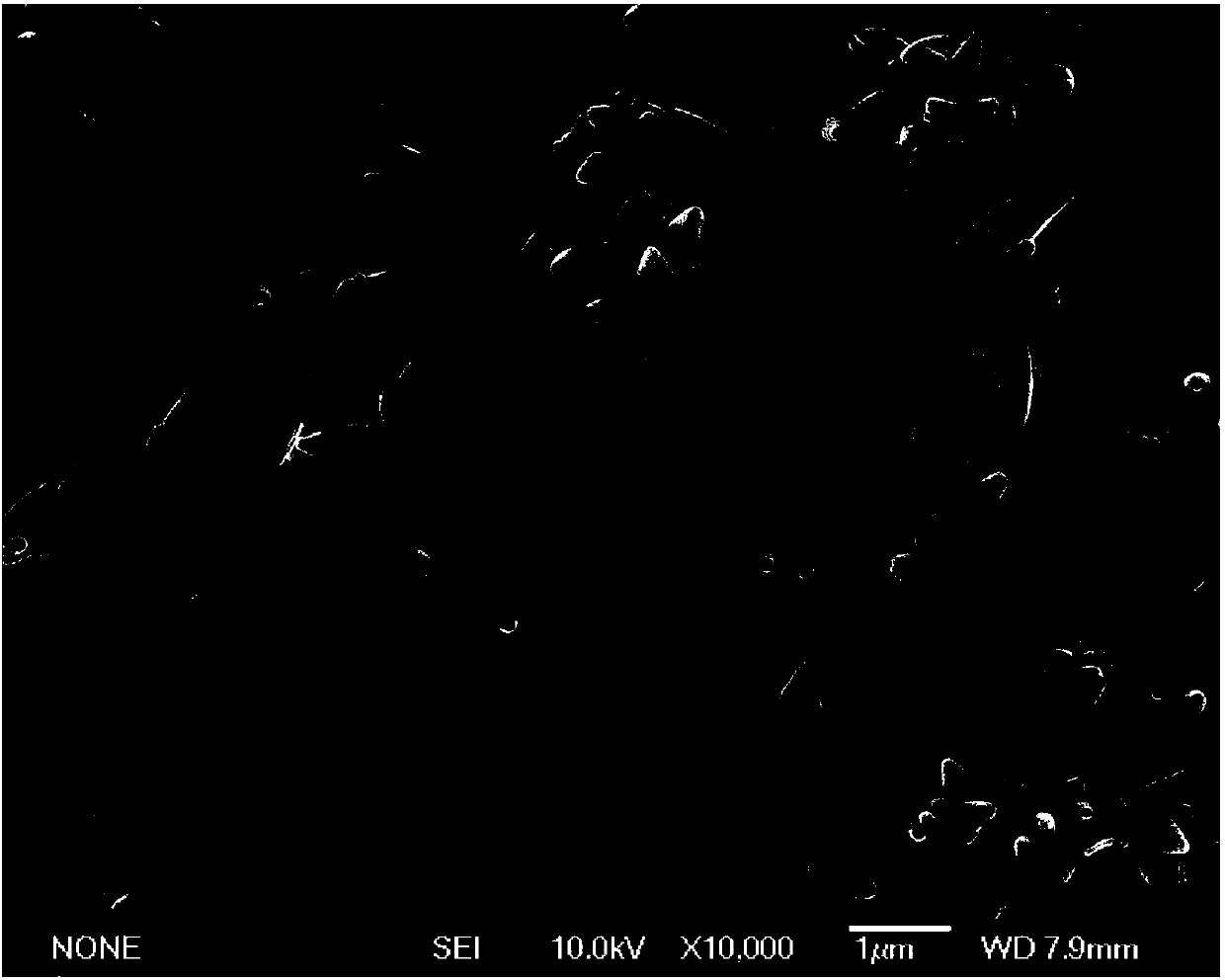

[0035] The automatic mechanical vertical steel kiln is adopted, the limestone with a size of 30-60mm is selected, the coal-stone ratio is 80kg / T limestone, the calcination temperature is controlled at 1000°C, and the calcination time is 25h. Lime is digested in hot water at 80°C, and the mass ratio of lime to water is 1:6. Add water to the digested coarse pulp to adjust the concentration to 15%, first pass through a 100-mesh sieve, and then pass through a hydrocyclone to remove impurities to obtain a fine pulp. After the seminal pulp was aged for 24 hours, the temperature was lowered to 40°C. Pour the fine slurry into a carbonization tower, add 1.5‰ citric acid (dry relative to PCC) (concentration: 30%) as a crystal form control agent, and stir evenly. Ventilate for carbonization, the kiln gas concentration is 30%, and continuously detect the conductivity online during the carbonization process. When the conductivity reaches the minimum and then increases by 0.5mS / cm, stop th...

Embodiment 3

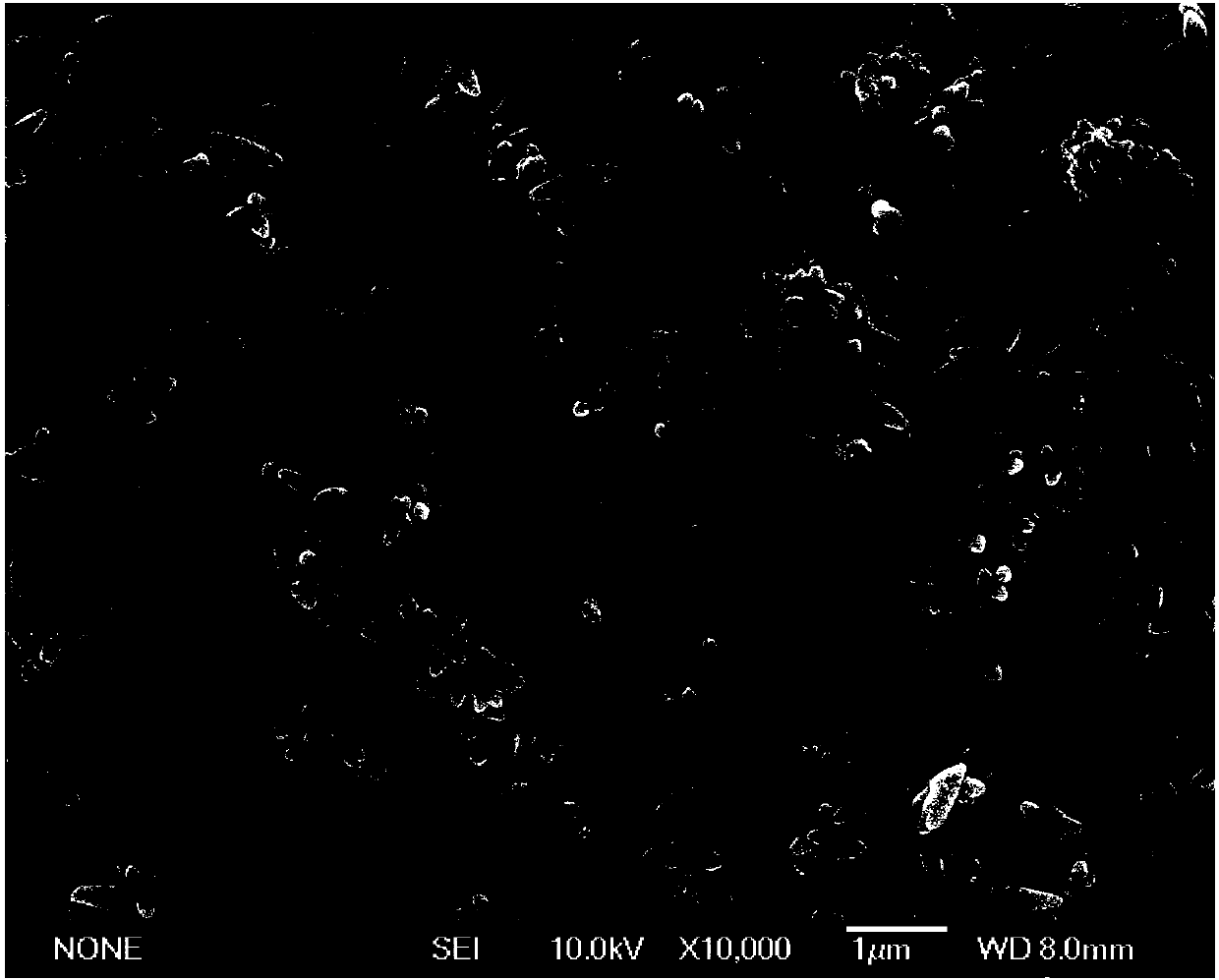

[0037] The automatic mechanical vertical steel kiln is adopted, the limestone with a size of 30-60mm is selected, the coal-stone ratio is 80kg / T limestone, the calcination temperature is controlled at 1000°C, and the calcination time is 25h. Lime is digested in hot water at 80°C, and the mass ratio of lime to water is 1:6. Add water to the digested coarse pulp to adjust the concentration to 15%, first pass through a 100-mesh sieve, and then pass through a hydrocyclone to remove impurities to obtain a fine pulp. After the seminal pulp was aged for 24 hours, the temperature was lowered to 35°C. Pour the fine slurry into a carbonization tower, add 2‰ citric acid (dry relative to PCC) (concentration: 30%) as a crystal form control agent, and stir evenly. Ventilate for carbonization, the kiln gas concentration is 30%, and continuously detect the conductivity online during the carbonization process. When the conductivity reaches the minimum and then increases by 0.5mS / cm, stop the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com