Low-cost and high-precision preparation method of carbon-based and metal-based electrode arrays

An electrode array, metal-based technology, applied in the direction of metal processing equipment, non-metal elements, chemical instruments and methods, etc., can solve the problems of complex preparation process of template filter membrane, difficulty in applying conductive materials, complicated filter devices, etc., and achieve structural composition Easy to adjust, wide range of substrates, good uniformity and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

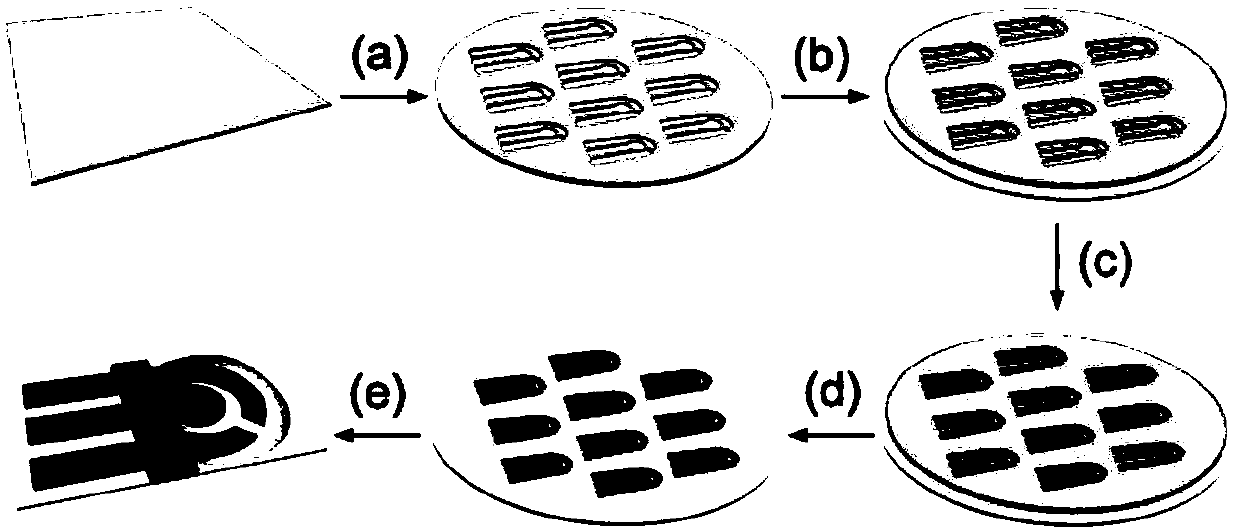

Method used

Image

Examples

preparation example Construction

[0039] Preparation of conductive material dispersion:

[0040] Dispersion 1

[0041] Add 60mg of single-walled carbon nanotubes (SWNTs) to 500mL of 5mM sodium dodecyl sulfate water (SDS) solution, ultrasonically disperse in a 50W ultrasonic instrument for 2 hours, and leave the black solution at room temperature for 2 days, collect The upper layer black solution, obtains the single-walled carbon nanotube stock solution dispersed in the SDS aqueous solution.

[0042] Dispersion 2

[0043] Add 2.5g of graphite powder to 500mL of N-methylpyrrolidone (NMP) solvent, ultrasonically disperse it in a 50W ultrasonic instrument for 6 hours, and leave the resulting black solution at room temperature for 2 days, collect the upper layer of the black solution, and obtain a solution dispersed in NMP Graphene stock solutions in .

[0044] Dispersion 3

[0045] Add 25mg of acetylene black to 5mL of N-methylpyrrolidone (NMP) solvent, ultrasonically disperse in a 50W ultrasonic instrument fo...

Embodiment 1

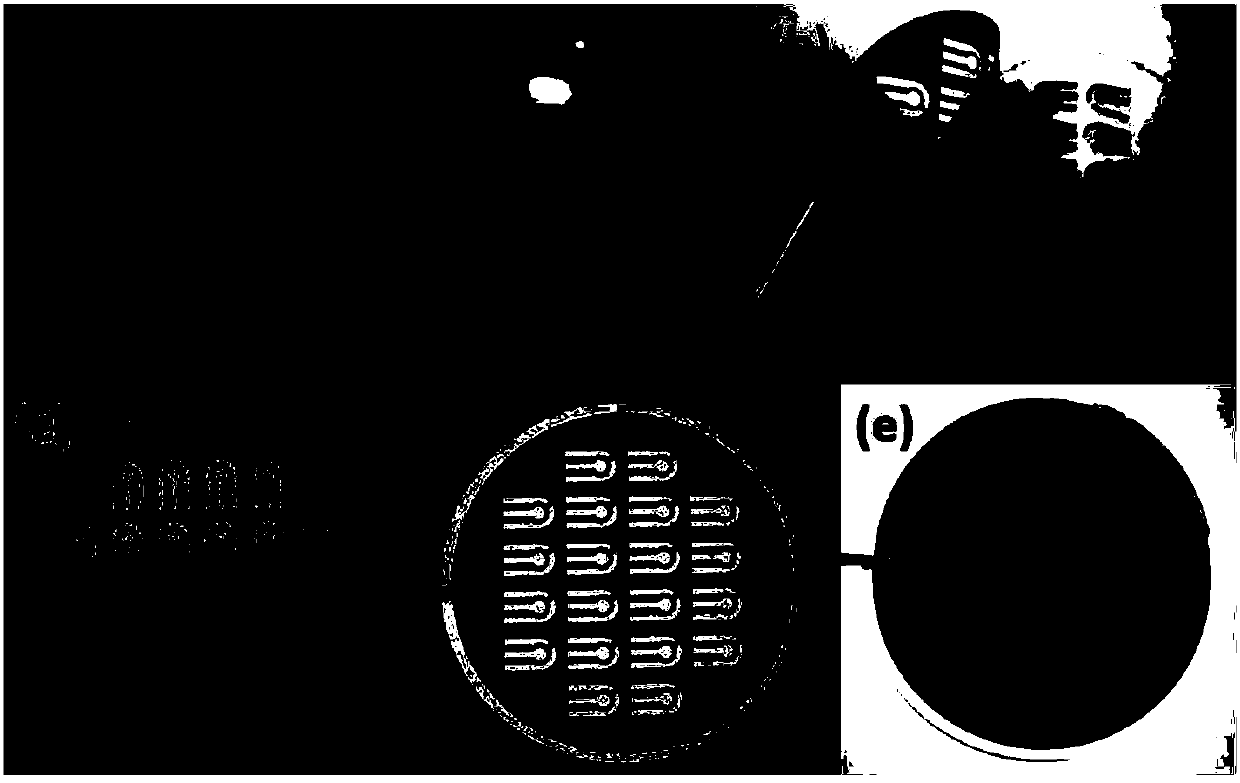

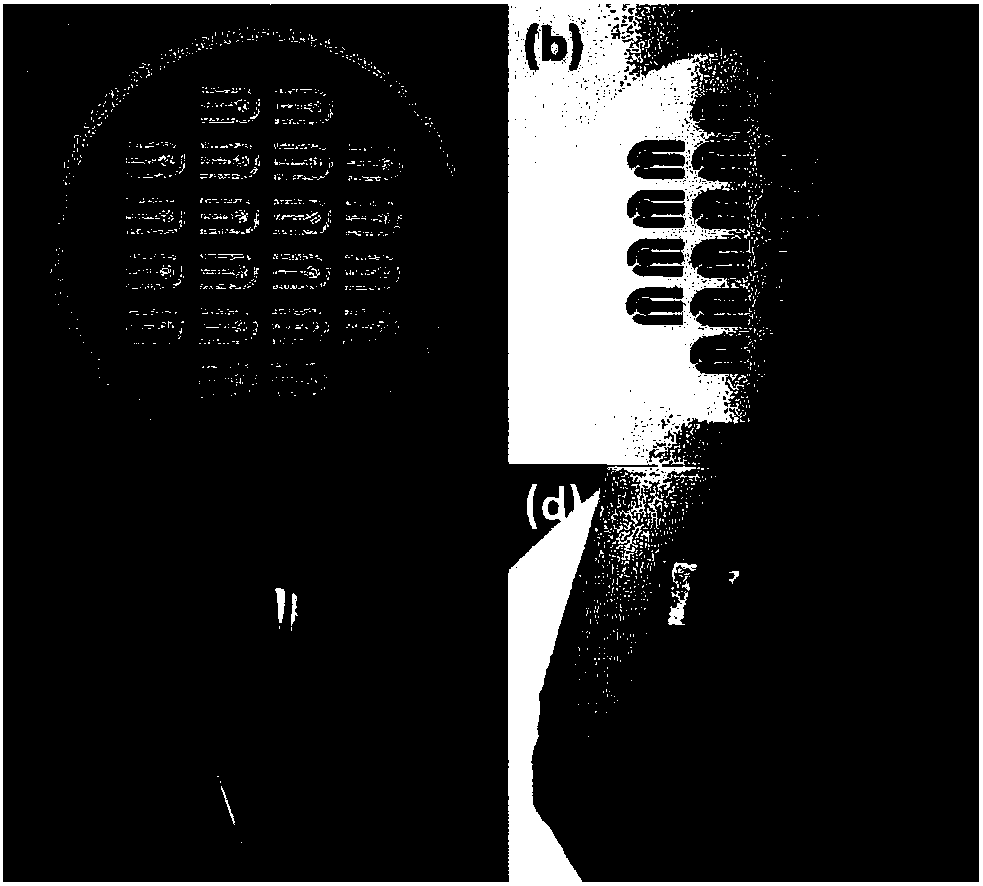

[0069] The filter template 1 was installed on the M50 cup filter of Shanghai Mosu Company, and its original 50mm diameter stainless steel backing plate was replaced by a porous titanium sheet with a diameter of 50mm and a pore diameter of 0.45 μm. Add 10mL of Dispersion 1 to 100mL of deionized water and stir evenly, ultrasonicate for 5 minutes, pour the solution directly into the filter cup of M50 cup filter, filter and dry under reduced pressure, then add 400mL of deionized water to wash several times, to remove residual SDS. The kraft paper template filter membrane with the conductive layer of single-walled carbon nanotubes deposited in the electrode array area was placed in a vacuum oven at 60°C and dried for 2 hours to obtain a single-walled carbon nanotube electrode array with a mixed cellulose filter membrane as a carrier and kraft paper partitions. Membrane resistance about 30Ω / sq (see figure 2 ).

Embodiment 2

[0071] Install the filter template 2 on the M50 cup filter of Shanghai Mosu Company, and wet it with 25% ethanol aqueous solution by volume, and replace the original 50mm stainless steel backing plate with a porous titanium sheet with a diameter of 50mm and a pore size of 0.45μm. Add 10mL of Dispersion 1 to 100mL of deionized water and stir evenly. Sonicate for 5 minutes. Pour the solution directly into an M50 filter cup equipped with a template filter membrane, filter under reduced pressure and drain, then add 400mL of deionized water to wash several times. , to remove residual SDS. Soak the PET template filter membrane with the conductive layer of single-walled carbon nanotubes deposited in the electrode array area in ethanol for 1 minute, carefully peel off the PET tape from the nitrocellulose filter membrane, and dry it in a vacuum oven at 60°C for 2 hours to obtain nitric acid The cellulose filter membrane is the single-walled carbon nanotube electrode array of the carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com