Absorbable bone wax with hemostasis function, and preparation method thereof

A bone wax and functional technology, applied in the field of biomedical materials, can solve the problems of foreign body reaction, poor biocompatibility of bone wax, and hinder the aggregation of blood components, etc., and achieve the effect of good biocompatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Weigh each raw material component according to the weight ratio: 33.3% of cross-linked hyaluronic acid, 33.3% of calcium phosphate, and 33.4% of deionized water;

[0027] 2. Put the cross-linked hyaluronic acid and calcium phosphate in a reaction vessel, mix them well by magnetic stirring, then add deionized water and stir to obtain the bone wax;

[0028] 3. The obtained bone wax is sealed and packaged, and sterilized by ultraviolet light.

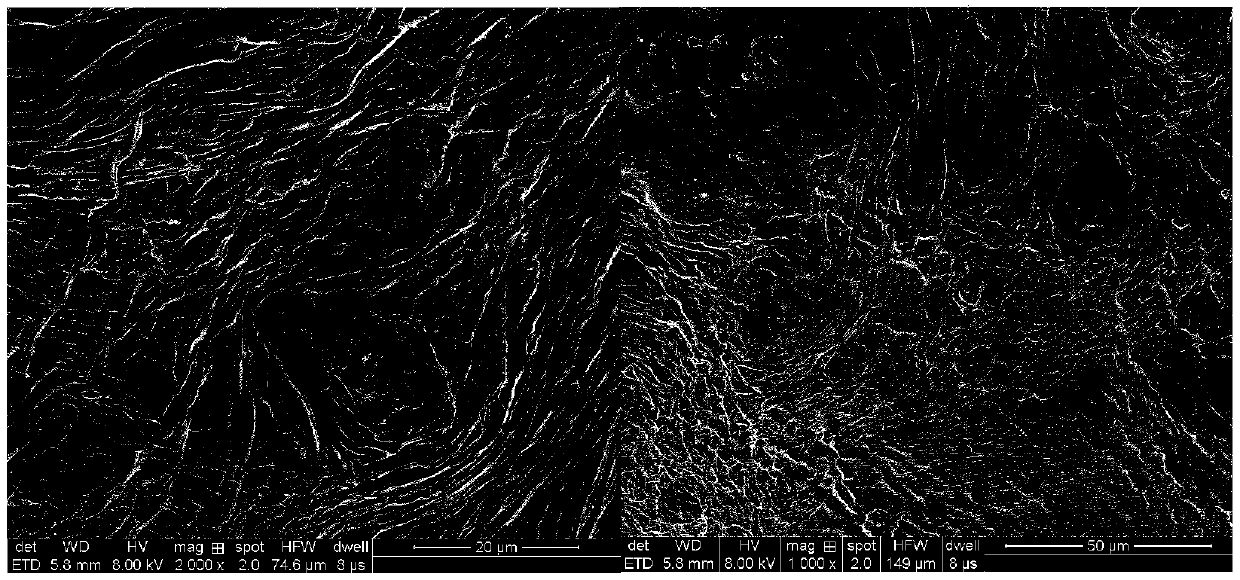

[0029] The results of electron microscopy scanning of the prepared materials are as follows: figure 1 Shown are the characterizations scanned at 20um and 50um respectively.

Embodiment 2

[0031] 1. Weigh each raw material component according to the weight ratio: 33.3% of cross-linked hyaluronic acid, 30% of calcium phosphate, 3.3% of soluble starch, and 33.4% of deionized water;

[0032] 2. Put the cross-linked hyaluronic acid and calcium phosphate in the reaction container, and mix them thoroughly by magnetic stirring;

[0033] 3. Add deionized water to the soluble starch, stir and heat to 60-70°C to make it pregelatinized, then add it to the reaction vessel in step 2 and mix well with other raw materials to obtain the bone wax;

[0034] 4. The obtained bone wax is sealed and packaged, and sterilized by ultraviolet light.

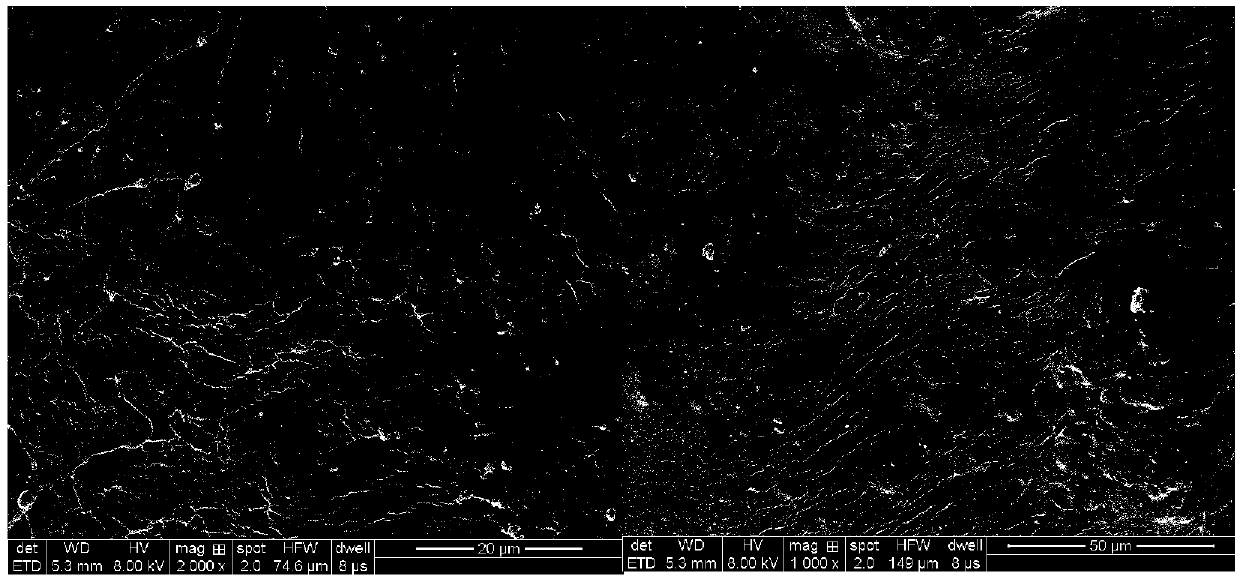

[0035] The results of electron microscopy scanning of the prepared materials are as follows: figure 2 Shown are the characterizations scanned at 20um and 50um respectively.

Embodiment 3

[0037] 1. Weigh each raw material component according to the weight ratio: 33.3% of cross-linked hyaluronic acid, 26.7% of calcium phosphate, 6.7% of soluble starch, and 33.3% of deionized water;

[0038] 2. Put the cross-linked hyaluronic acid and calcium phosphate in the reaction vessel, mix them thoroughly by magnetic stirring, and then add deionized water;

[0039] 3. Add deionized water to the soluble starch, stir and heat to 60-70°C to make it pregelatinized, then add it to the reaction vessel in step 2 and mix well with other raw materials to obtain the bone wax;

[0040] 4. The obtained bone wax is sealed and packaged, and sterilized by ultraviolet light.

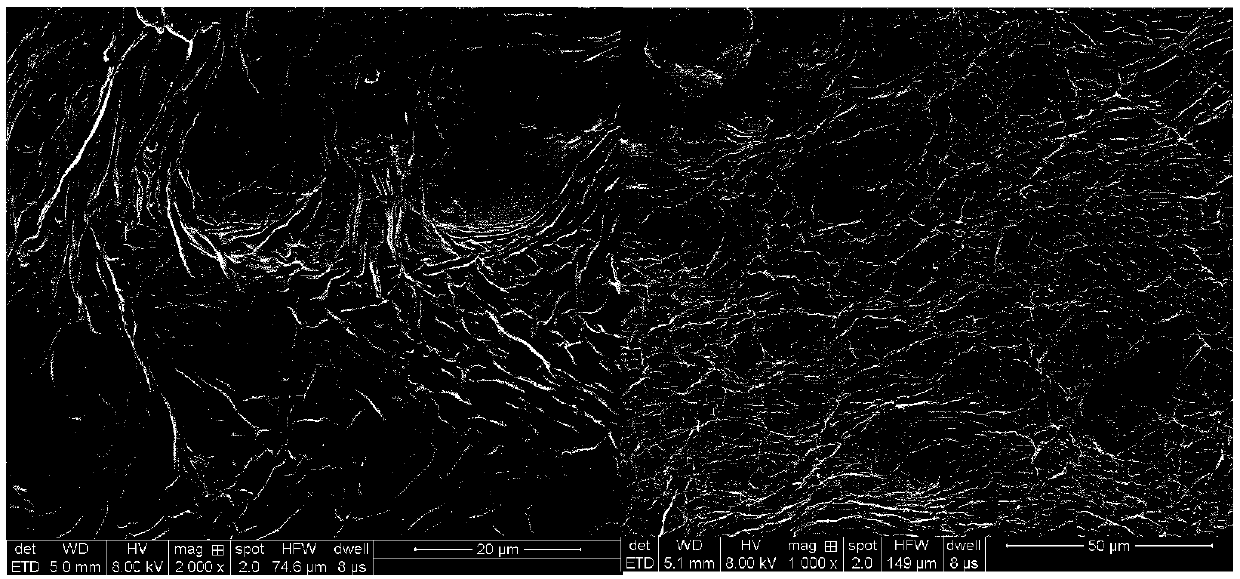

[0041] The results of electron microscopy scanning of the prepared materials are as follows: image 3 Shown are the characterizations scanned at 20um and 50um respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com