A kind of pre-esterification method for preparing biodiesel

A technology of biodiesel and pre-esterification, applied in chemical instruments and methods, biofuels, fatty acid esterification, etc., can solve the problems of unsuitability for industrial production, low conversion rate, complicated process, etc., to increase the probability of exposure and Mass transfer efficiency, increase reaction efficiency and conversion rate, and reduce the effect of acid value of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

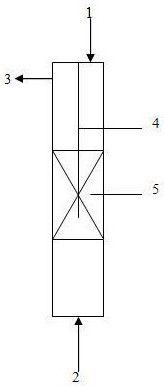

Image

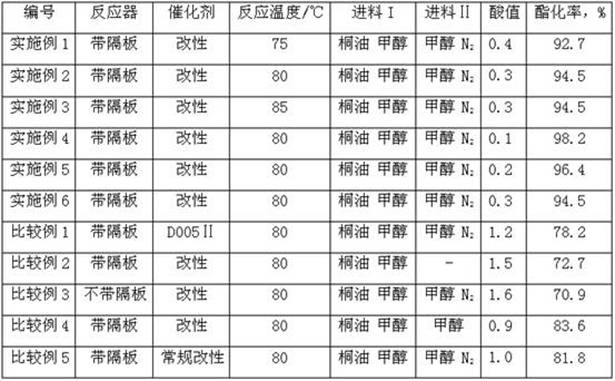

Examples

Embodiment 1

[0033] (1) Preparation of modified ion exchange resin catalyst: a: Wash 150 grams of styrene-based strongly acidic cation exchange resin with deionized water for 5 times, each time for 10 minutes, and dry it in a vacuum oven at 90°C for 4 hours; b : Put the dried strongly acidic cation exchange resin into a 2mm thick steel mesh bag, spread it flat in an ultrasonic vibrator with a vibration frequency of 58kHz, and use an atomizing nozzle with a 35% mass percentage of phosphotungstic acid aqueous solution and nitrogen Spray impregnation for 2 hours, spray distance 1cm, spray pressure 0.05MPa; c: After washing, dry in a vacuum oven at 90°C for 6 hours, and bake the dried ion exchange resin at 210°C for 8 hours; d: Then Treat the resin with 20% aqueous solution of phosphotungstic acid according to the method of b. After washing, dry it in a vacuum oven at 80°C for 6 hours, and roast the dried ion exchange resin at 200°C for 8 hours to obtain the loaded type heteropolyacid catalyst...

Embodiment 2

[0036] (1) Preparation of modified ion exchange resin catalyst: a: Wash 150 grams of styrene-based strongly acidic cation exchange resin with deionized water for 5 times, each time for 10 minutes, and dry it in a vacuum oven at 90°C for 6 hours; b : Put the dried strong acidic cation exchange resin into a 3mm thick steel mesh bag, lay it flat in an ultrasonic vibrator, the vibration frequency is 59kHz, and use an atomizing nozzle to spray phosphotungstic acid aqueous solution with a mass percentage of 35% and nitrogen Spray impregnation for 2 hours, spray distance 2cm, spray pressure 0.07MPa; c: After washing, dry in a vacuum oven at 90°C for 6 hours, and bake the dried ion exchange resin at 220°C for 8 hours; d: Then Treat the resin with 15% phosphotungstic acid aqueous solution according to the method b, after washing, dry it in a vacuum oven at 80°C for 6 hours, and roast the dried ion exchange resin at 200°C for 8 hours to obtain the supported type heteropolyacid catalyst....

Embodiment 3

[0039] (1) Preparation of modified ion exchange resin catalyst: a: Wash 150 grams of styrene-based strongly acidic cation exchange resin with deionized water for 5 times, each time for 10 minutes, and dry it in a vacuum oven at 90°C for 6 hours; b : Put the dried strongly acidic cation exchange resin into a 3mm thick steel mesh bag, lay it flat in an ultrasonic vibrator with a vibration frequency of 60kHz, and use an atomizing nozzle with a 45% mass percentage of phosphotungstic acid aqueous solution and nitrogen Spray impregnation for 2 hours, spray distance 2cm, spray pressure 0.06MPa; c: After washing, dry in a vacuum oven at 90°C for 6 hours, and bake the dried ion exchange resin at 220°C for 8 hours; d: Then Treat the resin with 20% aqueous solution of phosphotungstic acid according to the method of b. After washing, dry it in a vacuum oven at 80°C for 6 hours, and roast the dried ion exchange resin at 200°C for 8 hours to obtain the loaded type heteropolyacid catalyst. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com