Magnetic suspension intelligent flexible reducer system of robot and control method thereof

An intelligent control and reducer technology, applied in the field of intelligent robots, can solve the problems of insufficient innovation of precision reducers, late robot reducers, and low degree of intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

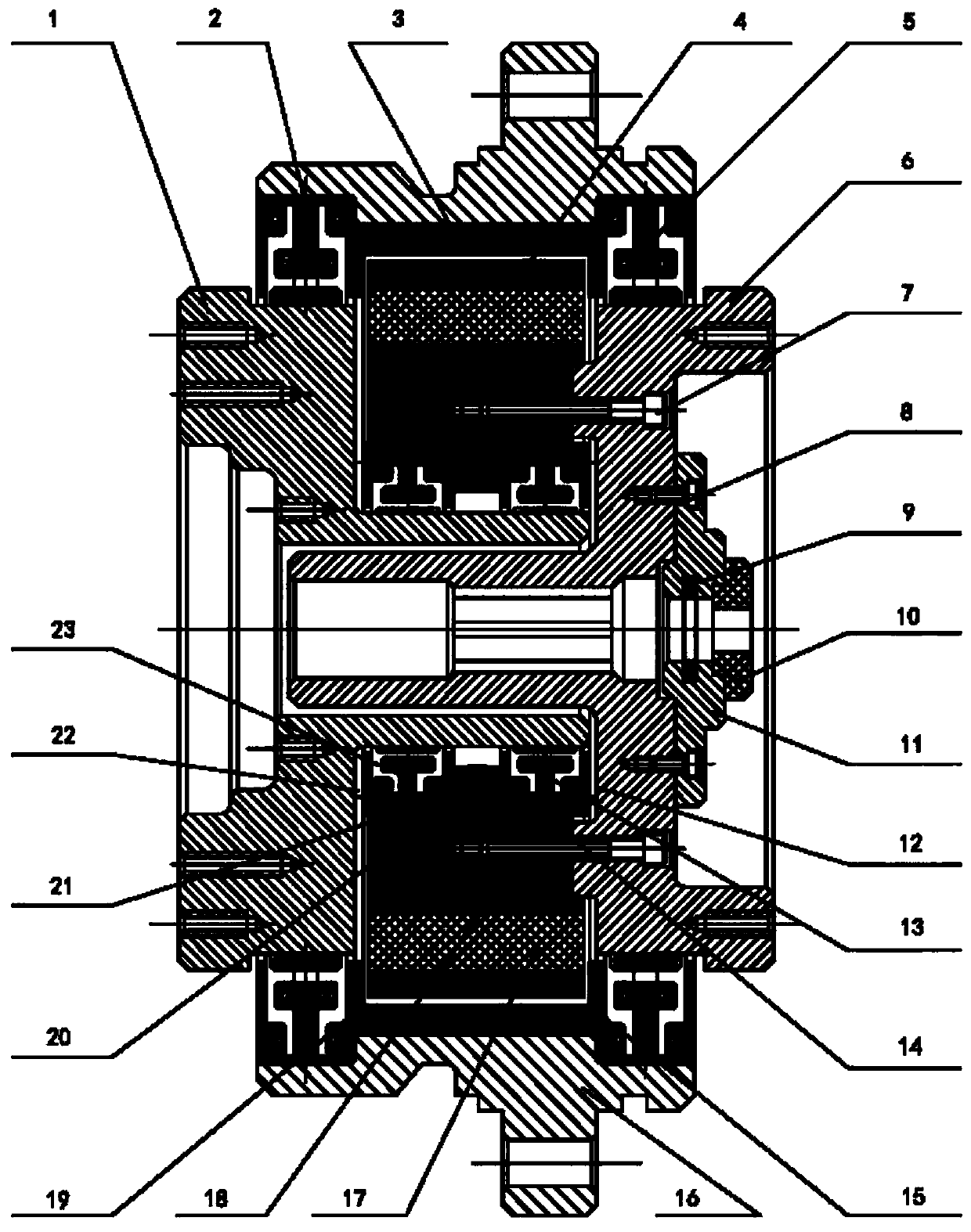

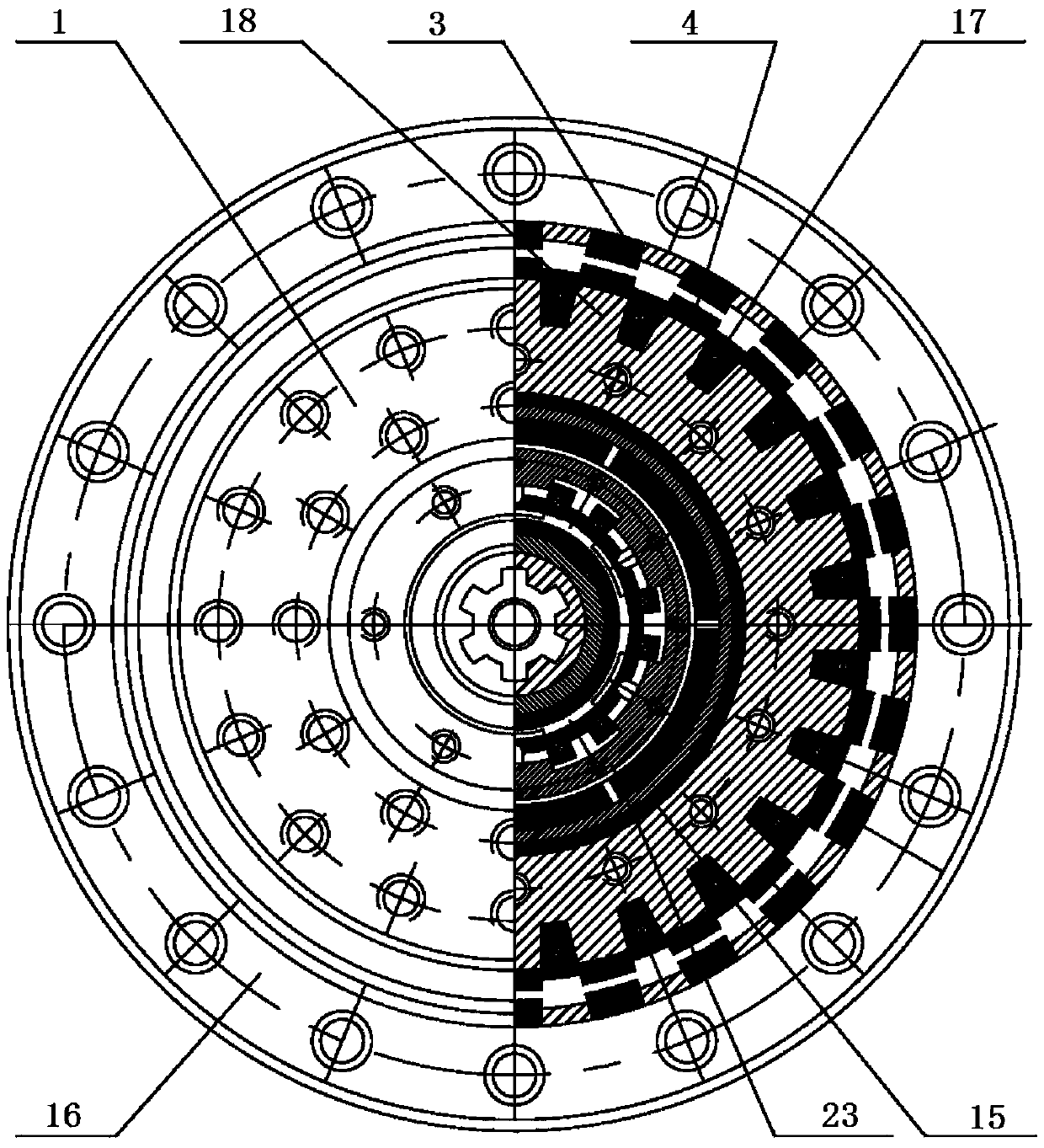

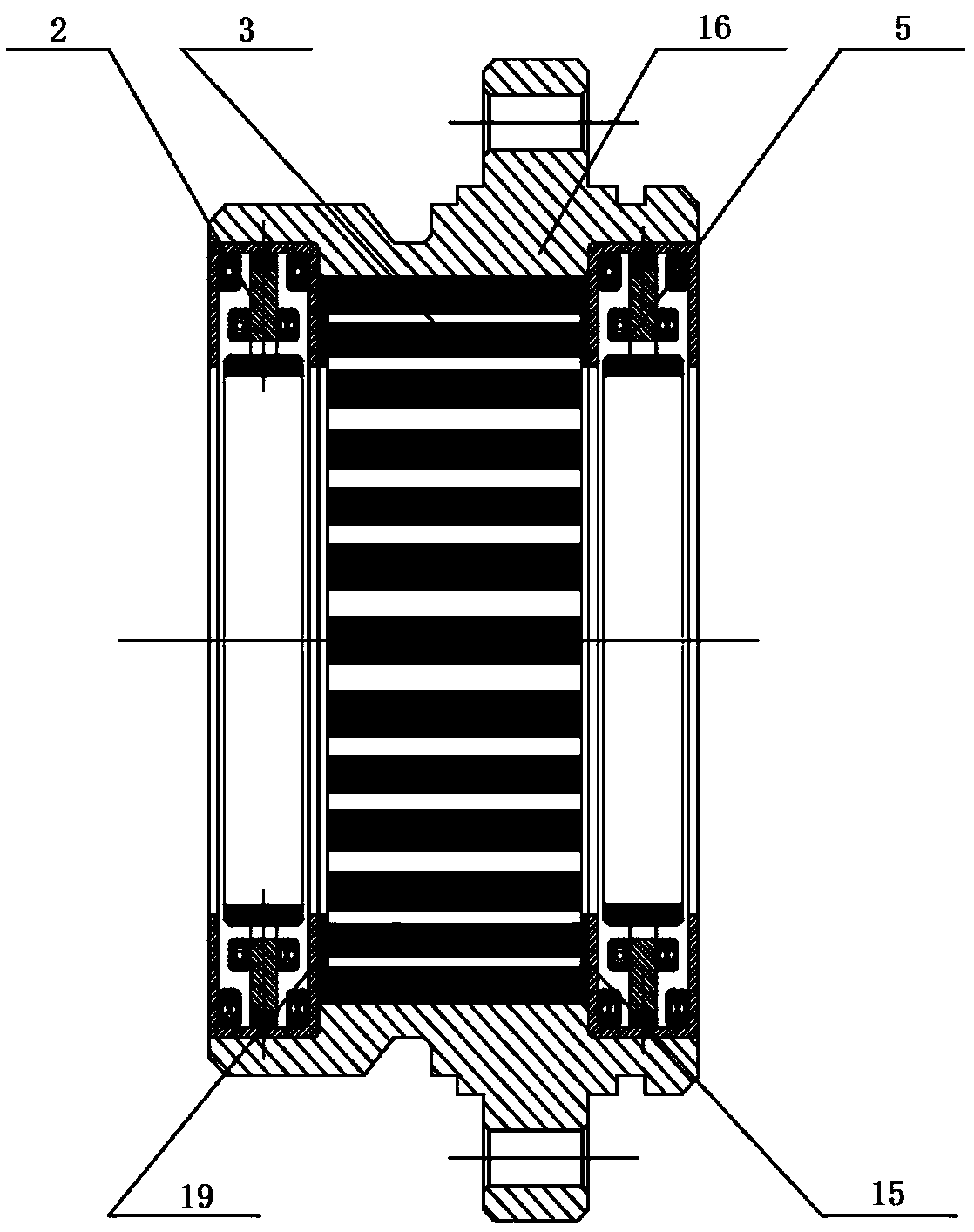

[0215] see Figure 1-Figure 20 , the robot maglev intelligent flexible reducer system of the present invention includes an intelligent flexible reducer system and an intelligent control electrical system; the intelligent flexible reducer system includes a precision mechanical reducer and a maglev transmission system; the intelligent control electrical system includes a man-machine dialogue system, remote wireless communication system, data acquisition feedback system, control system and mechanism execution system; the intelligent flexible reducer system includes inner rotor assembly, outer rotor assembly, inner rotor fixed shaft, inner rotor input shaft and electromagnetic levitation Bearing; the inner rotor assembly includes an inner rotor yoke, an inner rotor electromagnetic coil, and an inner rotor permanent magnet, and the inner rotor permanent magnet and the inner rotor electromagnetic coil are evenly spaced and embedded on the circumference of the inner rotor yoke, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com