Comprehensive utilization method of sulfamic acid production waste acid

A technology of sulfamic acid and waste acid, applied in chemical instruments and methods, aluminum sulfate, aluminum compounds, etc., can solve problems such as increasing the process of removing ammonia nitrogen, eutrophication of water body, black odor, quality not meeting the requirements, etc., to achieve Low production equipment requirements, high recovery rate, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

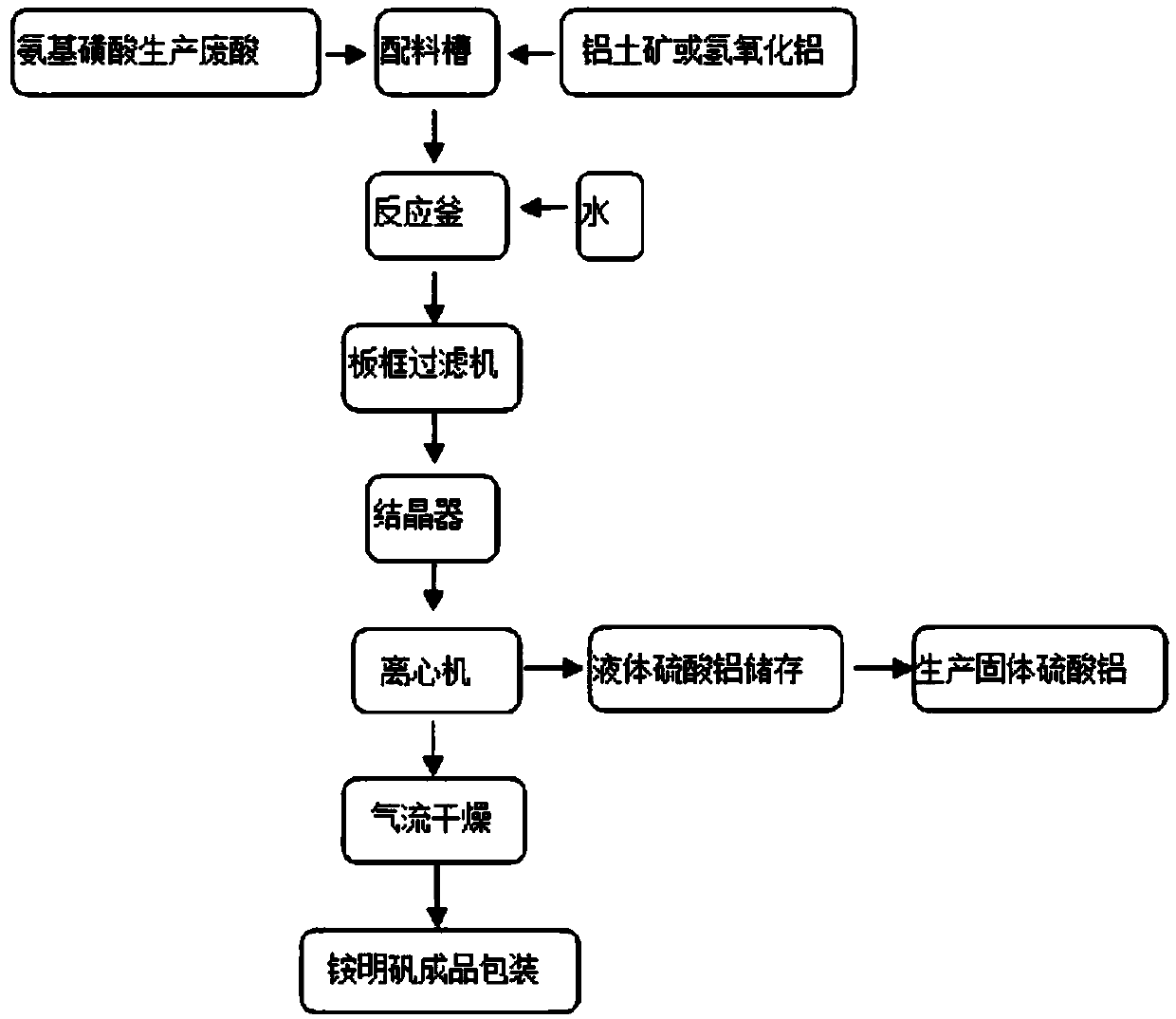

Image

Examples

Embodiment 1

[0029] A kind of sulfamic acid production waste acid comprehensive utilization method, used raw material is as follows:

[0030] 1, the massfraction of sulfuric acid is 58.3%, the massfraction of sulfamic acid is 1.5%, the massfraction of ammonium bisulfate is 9.5% sulfamic acid production waste acid;

[0031] 2. Bauxite with a mass fraction of alumina of 31.2%.

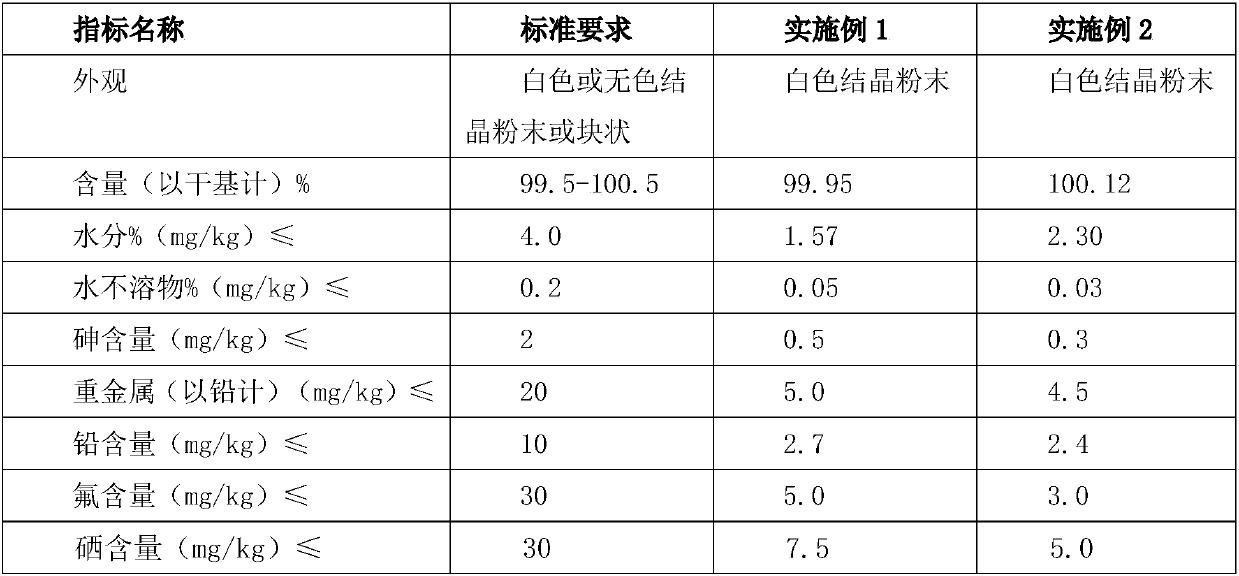

[0032] The above method for comprehensive utilization of waste acid from sulfamic acid production includes the following steps: mix 648 kg of bauxite and 1 ton of waste acid from sulfamic acid production in a batching tank evenly, then pump them into a reaction kettle, heat to 120° C. to initiate the reaction, and the pressure during the reaction is Controlled to 0.3MPa, after the reaction is completed, add 550kg of water to dilute the content of alumina in the reaction solution obtained from the reaction to 8.1wt%, then filter with a plate and frame filter press to obtain a mixed solution of aluminum sulfate and amm...

Embodiment 2

[0034] A kind of sulfamic acid production waste acid comprehensive utilization method, used raw material is as follows:

[0035] 1, the massfraction of sulfuric acid is 58.3%, the massfraction of sulfamic acid is 1.5%, the massfraction of ammonium bisulfate is 9.5% sulfamic acid production waste acid;

[0036] 2. Bauxite with a mass fraction of alumina of 48.3%.

[0037] The above method for comprehensive utilization of waste acid from sulfamic acid production includes the following steps: mix 419 kg of bauxite and 1 ton of waste acid from sulfamic acid production in a batching tank evenly, then pump them into the reaction kettle, heat to 120°C to initiate the reaction, and the pressure during the reaction is Control to 0.3MPa, after the reaction is completed, add 550kg of water to dilute the content of alumina in the reaction solution obtained from the reaction to 8.3wt%, then filter with a plate and frame filter press to obtain a mixed solution of aluminum sulfate and ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com