A kind of preparation method of nano cerium oxide particle

A technology of nano-cerium oxide and particles, which is applied in the field of preparation of nano-cerium oxide particles, can solve the problems of poor application performance, poor dispersion, and easy agglomeration of nano-CeO, and achieves controllable particle size, simple preparation process, The effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

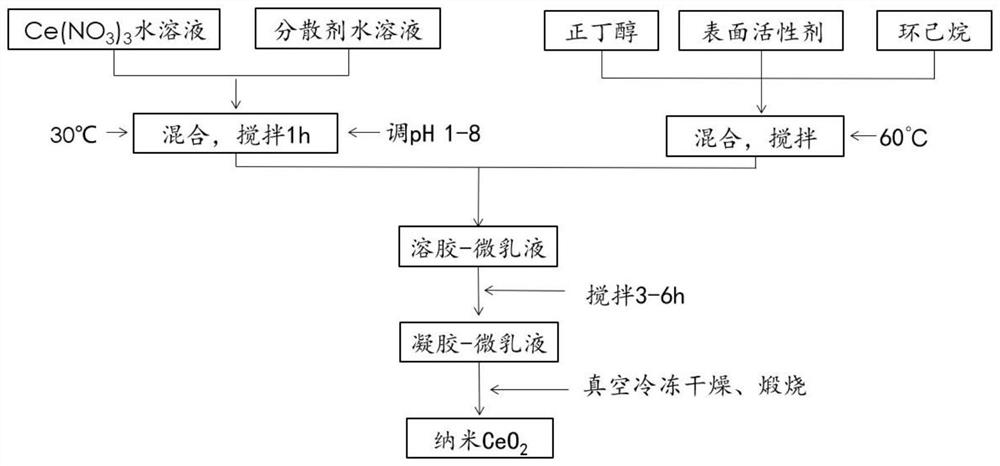

Method used

Image

Examples

Embodiment 1

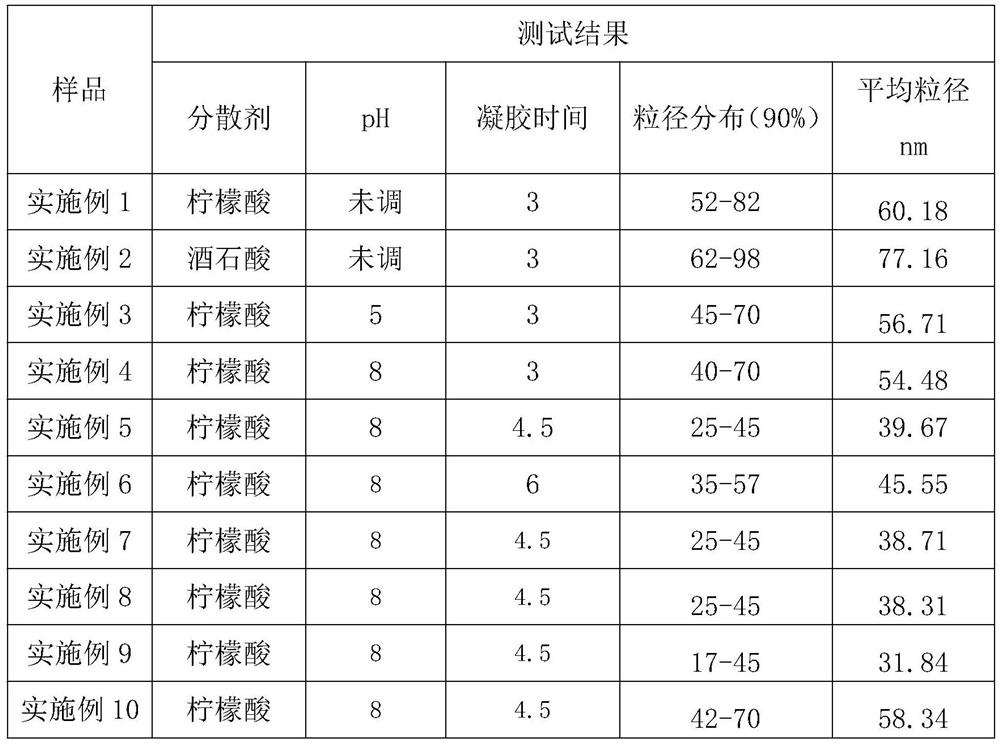

[0027] Weigh 1.085g Ce(NO 3 ) 3 ﹒ 6H 2 O was dissolved in 1ml of deionized water; then 1.44g of citric acid was weighed and dissolved in 1.5ml of deionized water. After mixing the two solutions, without adjusting the pH value, stirred at 30°C for 1h to form a sol; Hexane, start stirring, control the temperature of the reaction system at 60±2°C, add 0.87g of cetyltrimethylammonium bromide, 1.0ml of n-butanol and 1.5ml of the sol prepared by the surface active wrapping agent to form a stable sol-inverse microemulsion system, keep the temperature of the water bath constant, and continue to stir for 3 hours to form gel particles; cool the gel particles to 0~-30°C to freeze, suction filter at low temperature, and use- Repeated washing with absolute ethanol at 20°C; then vacuum freeze-drying at -60°C for 24 hours to obtain the precursor; calcining the precursor at 500°C for 3 hours to obtain nano-cerium oxide. The measured SEM image is as follows figure 1 shown. The measured p...

Embodiment 2

[0029] Weigh 1.085g Ce(NO 3 ) 3 ﹒ 6H 2 O was dissolved in 1ml of deionized water; then 1.41g of tartaric acid was weighed and dissolved in 1.5ml of deionized water, and the two solutions were mixed without adjusting the pH value, and stirred at 30°C for 1 hour to form a sol; 50ml of cyclohexyl alkane, start stirring, control the temperature of the reaction system at 60±2°C, add 0.87g of cetyltrimethylammonium bromide, 1.0ml of n-butanol and 1.5ml of the prepared sol to the reactor in sequence, the sol is made of surfactant Wrap to form a stable sol-inverse microemulsion system, keep the temperature of the water bath constant, continue to stir for 3 hours, and form gel particles; cool the gel particles to 0~-30°C to freeze, filter at low temperature, and use -20 Repeated washing with absolute ethanol at ℃; then vacuum freeze-drying at -60°C for 24 hours to obtain the precursor; calcining the precursor at 500°C for 3 hours to obtain nano-cerium oxide. The measured particle s...

Embodiment 3

[0031] Weigh 1.085g Ce(NO 3 ) 3 ﹒ 6H 2 O was dissolved in 1ml of deionized water; then 1.44g of citric acid was weighed and dissolved in 1.5ml of deionized water, after mixing the two solutions, the pH was adjusted to 5 with 25% ammonia water, and stirred at 30°C for 1h to form a sol; Add 50ml of cyclohexane into the reactor, start stirring, control the temperature of the reaction system at 60±2°C, add 0.87g of cetyltrimethylammonium bromide, 1.0ml of n-butanol and 1.5ml of the prepared sol to the reactor in sequence, The sol is wrapped by a surfactant to form a stable sol-inverse microemulsion system. Keep the temperature of the water bath constant and continue to stir for 3 hours to form gel particles; cool the gel particles to 0~-30°C to freeze, and pump them at low temperature. Filter and wash repeatedly with -20°C absolute ethanol; then vacuum freeze-dry at -60°C for 24 hours to obtain the precursor; calcinate the precursor at 500°C for 3 hours to obtain nano-cerium ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com