High-strength and anti-warping polyolefin composite material and preparation method thereof

A composite material and polyolefin technology, which is applied in the field of high-strength and warpage-resistant polyolefin composite materials and their preparation, can solve the problems of large difference in shrinkage rate, reducing the shrinkage rate of polypropylene molding, affecting assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

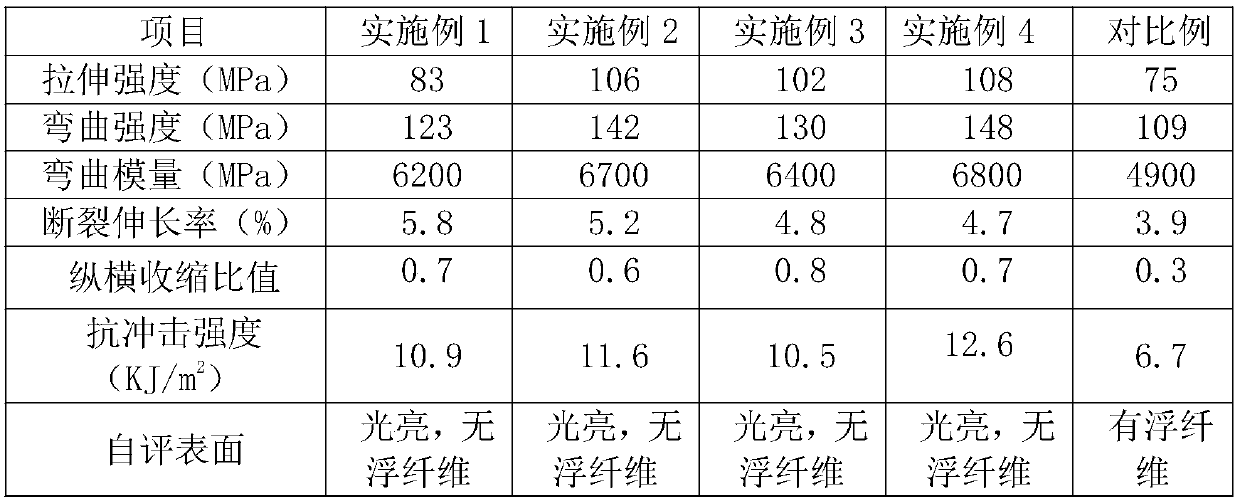

Examples

Embodiment 1

[0063] In terms of components by weight, the high-strength warpage-resistant polyolefin composite material of this embodiment includes the following components and parts by weight: 50 parts of homopolypropylene; 0.4 parts of zinc stearate; 2-hydroxyl-4- 0.2 parts of n-octyloxybenzophenone; 2 parts of nucleating agent masterbatch; 0.8 parts of high molecular weight silicone masterbatch; 12 parts of flat glass fiber; 1 part of maleic anhydride grafted polypropylene. in:

[0064] The length of the flat glass fiber in this embodiment is 3 mm, and its cross section is a rectangular structure with a length of 24 μm and a width of 6 μm.

[0065] The silicone content of the high molecular weight silicone masterbatch in this embodiment is 40%.

[0066] The nucleating agent masterbatch of the present embodiment is made up of maleic anhydride grafted polypropylene and nucleating agent, and the mass ratio of this nucleating agent is 3.0%, is made up of aluminum hydroxide, magnesium hydro...

Embodiment 2

[0073] In terms of components by weight, the high-strength warpage-resistant polyolefin composite material of this embodiment includes the following components and parts by weight: 90 parts of copolymerized polypropylene; 1 part of zinc stearate; 2-hydroxyl-4-n- 1 part of octyloxybenzophenone; 6 parts of nucleating agent masterbatch; 5 parts of high molecular weight silicone masterbatch; 45 parts of flat glass fiber; 6 parts of maleic anhydride grafted methacrylate containing organic silicon, ma The grafting rate of toic anhydride was 1.2%. in:

[0074] The length of the flat glass fiber in this embodiment is 5 mm, and its cross section is a rectangular structure with a length of 30 μm and a width of 8 μm.

[0075] The silicone content of the high molecular weight silicone masterbatch in this embodiment is 55%.

[0076] The maleic anhydride grafted organosilicon-containing methacrylate of the present embodiment is prepared by the following method:

[0077] Step 1: Weigh the...

Embodiment 3

[0089] In terms of components by weight, the high-strength warpage-resistant polyolefin composite material of this embodiment includes the following components and parts by weight: 60 parts of homopolypropylene; 0.6 parts of zinc stearate; 2-hydroxyl-4- 0.6 parts of n-octyloxybenzophenone; 4 parts of nucleating agent masterbatch; 3 parts of high molecular weight silicone masterbatch; 30 parts of flat glass fiber; 3 parts of maleic anhydride grafted polypropylene, maleic anhydride grafting ratio 1.0%. in:

[0090] The length of the flat glass fiber in this embodiment is 3 mm, and its cross section is a rectangular structure with a length of 28 μm and a width of 7 μm.

[0091] The silicone content of the high molecular weight silicone masterbatch in this embodiment is 48%.

[0092] The nucleating agent master batch of this embodiment is composed of isotactic polypropylene and acrylonitrile-styrene copolymer, and the mass ratio of the nucleating agent is 3.0%, and the nucleatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com