Pesticide microcapsule with easily-adjusted release rate and preparation method of pesticide microcapsule

A release rate and pesticide technology, applied in the fields of botanical equipment and methods, plant growth regulators, animal repellents, etc., can solve the problems of changing the release rate, rupture of the capsule wall, difficult to control the release rate, etc. The effect of convenient regulation and easy control of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The present invention also provides a method for preparing pesticide microcapsules that is easy to adjust the release rate, which specifically includes the following steps:

[0102] (1) According to the above-mentioned a kind of pesticide microcapsule that is easy to adjust the release rate, and weigh the isocyanate and polyurethane soft segment according to the mass ratio of 2 to 5:8 to 5, and weigh the chain extender and organic solvent at the same time, set aside ;

[0103] (2) Mix isocyanate, polyurethane soft segment and oil-based pesticide evenly to form an oil phase or add isocyanate, polyurethane soft segment capsule material and pesticide to an organic solvent to prepare an oil phase, and heat the oil phase to 40-70°C for later use ;

[0104] (3) Mix dispersant, defoamer and water evenly to prepare water phase, and heat the water phase to 40-70°C; dispersant 1%-10%, defoamer 0%-2%, dispersant includes Any one of lignosulfonate, alkylphenol polyoxyethylene eth...

Embodiment 1

[0110] A kind of preparation method of the 20% trifluralin microcapsule suspension that is easy to regulate release rate, specifically comprises the steps:

[0111] (1) Weigh 40g trifluralin, 5g toluene diisocyanate, 5g PEA1000 (polyethylene adipate glycol, molecular weight 1000), 3g lignosulfonate dispersant, 0.2g organosilicon defoamer , 2g ethylenediamine chain extender and 46.8g water, spare;

[0112] (2) Oil phase preparation: mix 40g of trifluralin, 5g of toluene diisocyanate, and 5g of PEA1000 (polyethylene adipate glycol, molecular weight 1000) evenly, and heat to 70°C for later use;

[0113] (3) Water phase preparation: mix 3g of lignosulfonate dispersant, 0.2g of silicone defoamer and 46.8g of water evenly, and heat to 70°C for later use;

[0114] (4) Emulsification: first add the water phase to the shearing machine, set the speed of the shearing machine to 1000r / min, then slowly drop the oil phase into the water phase, and continue shearing for 3 minutes to obtain ...

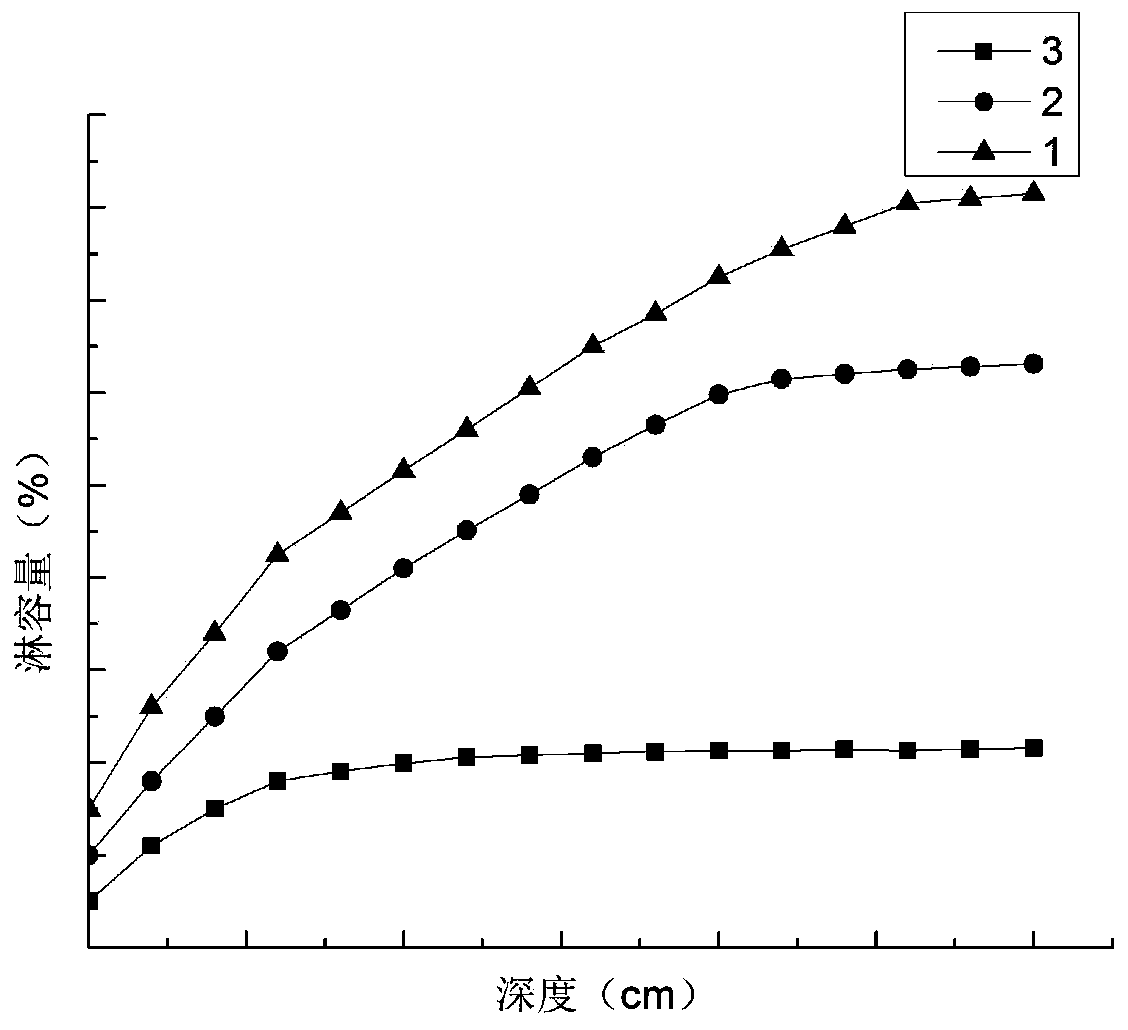

Embodiment 2

[0118] The 5g PEA1000 (polyethylene adipate diol, molecular weight 1000) used in the above-mentioned embodiment 1 is replaced with 5g PEA2000 (polyethylene adipate diol, molecular weight 2000), other operation steps, technology Parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com