Triamcinolone acetonide microsphere preparation and preparation method thereof

A technology of microspheres and preparations, which is applied in the field of medicine, can solve the problems of small force, increase of solvent residues in microspheres, and pollute the environment, and achieve the effects of reducing usage, improving drug stability, and reducing residual solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

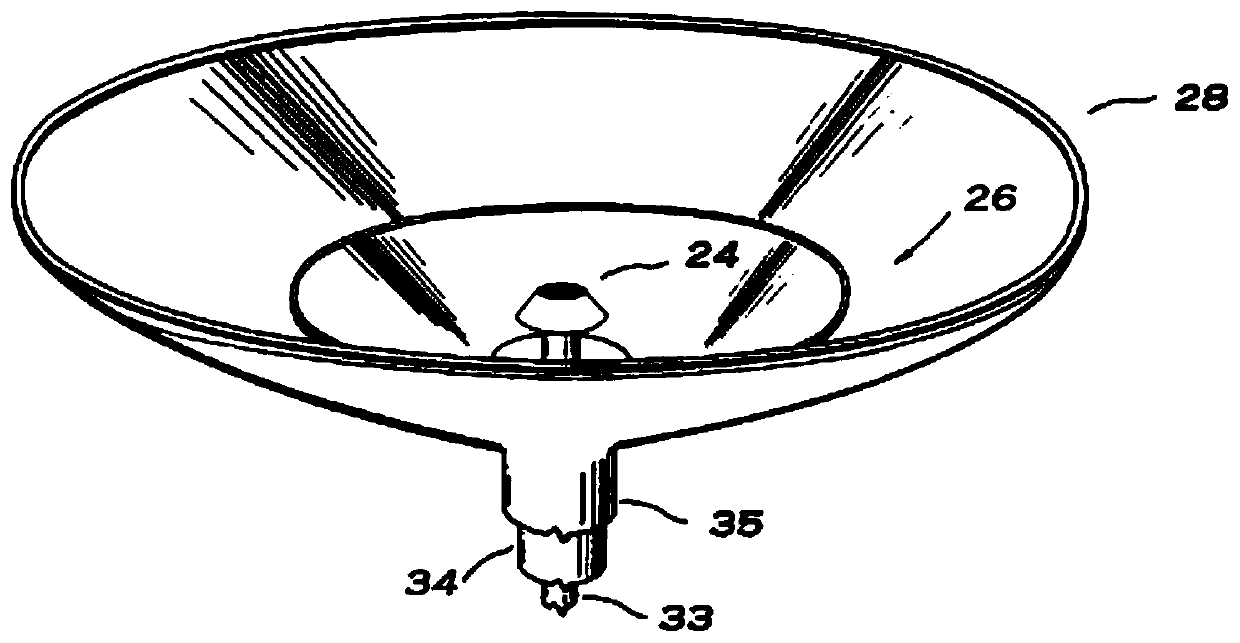

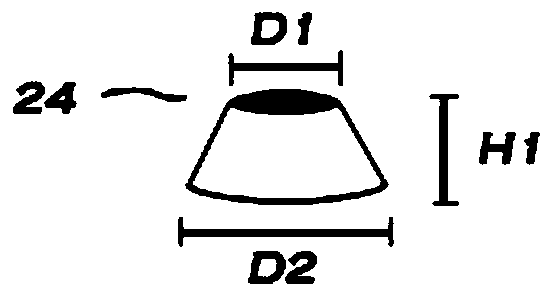

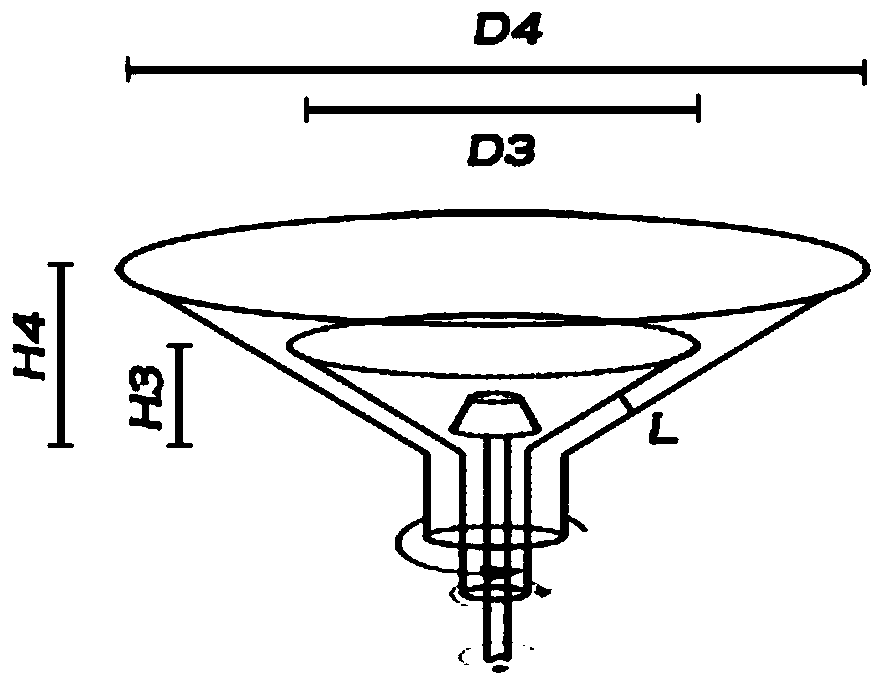

[0042] like Figure 1-3 As shown, a turntable device for producing droplets from liquid materials, the device is a turntable structure, a cup-shaped container 24 and its first driving device 33 are arranged in the center of the turntable structure, and the outside of the cup-shaped container 24 At least two layers of butterfly turntables are sequentially nested, and each layer of butterfly turntables is equipped with a corresponding driving device. Two layers of butterfly turntables are provided in the accompanying drawings, that is, the first layer of butterfly turntables 26 and the second layer of butterfly turntables 28, the first layer of butterfly turntables 26 are driven to rotate by the second drive device 34, and the second layer of butterfly turntables 28 is driven to rotate by the third driving device 35, and the first driving device 33, the second driving device 34 and the third driving device 35 can be high-speed rotary motors, or strong magnetic high-speed motors....

Embodiment 2

[0047] like Figure 4 Shown, a kind of equipment for making microsphere, described equipment comprises main tank body 23 and embodiment 1 and is used for producing the turntable device of liquid material droplet, the bottom of described turntable device is supported by auxiliary structure 39 is installed in the main tank body 23;

[0048] The main tank 23 is an inverted tapered stainless steel double-layer tank capable of withstanding positive pressure, and a first temperature control element 40 that can adjust temperature is installed on the side wall of the tank. The first temperature control element 40 may be a temperature control water bath placed outside the jacket layer of the main tank body 23 .

[0049] The minimum inner diameter of the main tank body 23 is preferably more than 80 cm. When the longest diameter disc-shaped turntable rotates at the highest rotational speed, the droplets that fly out do not contact the inner wall of the main tank body 23 . Any target pa...

Embodiment 3

[0067] (1) Weigh 25g of triamcinolone acetonide and 75g of PLGA7525 (intrinsic viscosity 0.6dL / g) and disperse them in 75g of dichloromethane solvent, and the final viscosity of the obtained homogeneous solution is 374cp;

[0068] ⑵The homogeneous solution described in step ⑴ is supplied into the cup-shaped container through the liquid supply port (liquid supply speed 5mL / min), adjust the rotating drive device, set the cup-shaped container speed to 40m / s, and the speed of the first layer of disc-shaped turntable The rotational speed of the disc-shaped turntable on the second layer is 110m / s, and the rotational speed of the third-layer disc-shaped turntable is 130m / s. Under the action of centrifugal force, the material liquid in the cup-shaped container crosses the mouth of the cup and hits the opposite direction. The surface of the first layer of disc-shaped turntable is dispersed into droplets, and the formed droplets continue to hit the second layer of disc-shaped turntable r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com