Acylated nanocellulose crystal modified self-cleaning glass and preparation method thereof

A nanocellulose, self-cleaning technology, applied in the field of self-cleaning glass, can solve the problems of high risk factor, a lot of human resources, waste of water resources, etc., and achieve the effects of good biodegradability, high specific surface area, and easy modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

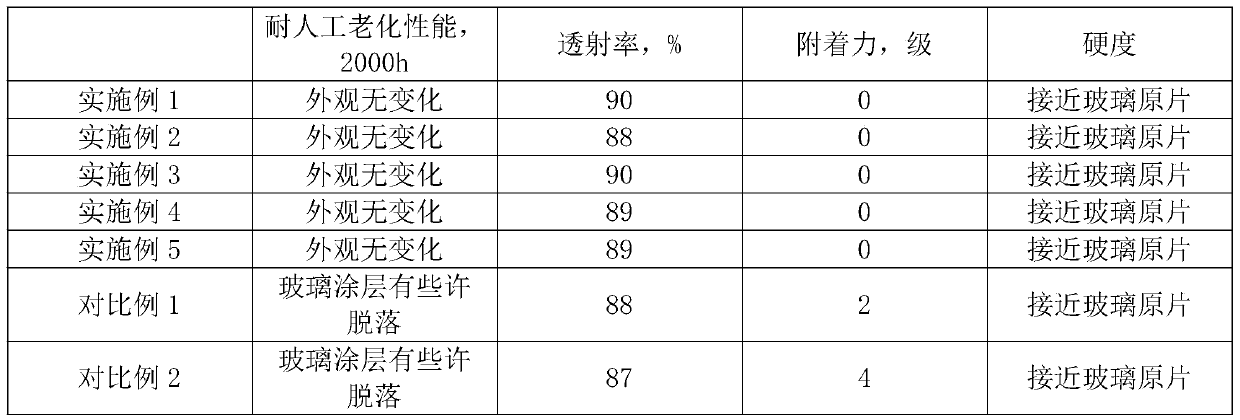

Examples

Embodiment 1

[0028] A preparation method of self-cleaning glass modified by acylated nanocellulose crystals, comprising the following steps:

[0029] (1) Place 1 g of microcrystalline cellulose in 50 mL of 50-60% sulfuric acid solution with a mass concentration of 50°C for 1 hour in a water bath, then cool to room temperature, add the reaction product to deionized water and let it stand for stratification, remove For the supernatant, place the residue in 60 mL of 10% sodium hydroxide solution and treat it in a water bath at 40-50°C for 1 hour, then centrifuge it, wash the solid and dry it to obtain nanocellulose crystals;

[0030] (2) Place 1 g of nanocellulose crystals in 50 mL of DMF solution, add 0.065 g of maleic acid and 0.022 g of maleic anhydride, and carry out acylation treatment under the action of 0.005 g of sulfuric acid; obtain acylated nanocellulose crystals;

[0031](3) Titanium isopropoxide is dissolved in absolute ethanol to obtain a titanium isopropoxide solution with a ma...

Embodiment 2

[0035] A method for preparing self-cleaning glass modified by nanocellulose acylate crystals, comprising the following steps:

[0036] (1) Place 1 g of microcrystalline cellulose in 50 mL of 50-60% sulfuric acid solution with a mass concentration of 50 ° C for 3 hours in a water bath, then cool to room temperature, add the reaction product to deionized water and let it stand for stratification, remove For the supernatant, place the residue in 60 mL of 10% sodium hydroxide solution and treat it in a water bath at 40-50°C for 1 hour, then centrifuge it, wash the solid and dry it to obtain nanocellulose crystals;

[0037] (2) Place 1g of nanocellulose crystals in 50mL of DMF solution, add 0.125g of maleic acid and 0.022g of maleic anhydride, and carry out acylation treatment under the action of 0.025g of sulfuric acid; obtain acylated nanocellulose crystals;

[0038] (3) Titanium isopropoxide is dissolved in absolute ethanol to obtain a titanium isopropoxide solution with a mass ...

Embodiment 3

[0042] A method for preparing self-cleaning glass modified by nanocellulose acylate crystals, comprising the following steps:

[0043] (1) Place 1 g of microcrystalline cellulose in 50 mL of 50-60% sulfuric acid solution with a mass concentration of 50 ° C for 2 hours in a water bath, then cool to room temperature, add the reaction product to deionized water and let it stand for stratification, remove For the supernatant, place the residue in 60 mL of 10% sodium hydroxide solution and treat it in a water bath at 40-50°C for 1 hour, then centrifuge it, wash the solid and dry it to obtain nanocellulose crystals;

[0044] (2) Place 1g of nanocellulose crystals in 50mL of DMF solution, add 0.07g of maleic acid and 0.022g of maleic anhydride, and carry out acylation treatment under the action of 0.008g of sulfuric acid; obtain acylated nanocellulose crystals;

[0045] (3) Titanium isopropoxide is dissolved in absolute ethanol to obtain a titanium isopropoxide solution with a mass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com