A kind of external wall environmental protection thermal insulation material

A thermal insulation material and environmental protection technology, applied in the field of building materials, can solve the problems of low structural strength, achieve the effects of reducing through-hole pores, reasonable pore structure, and increasing surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

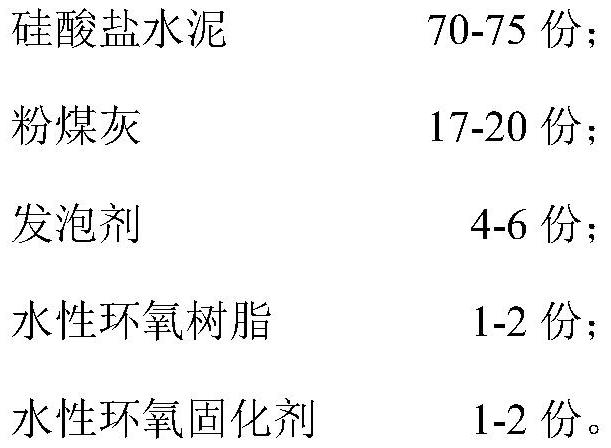

[0035] An environmentally friendly thermal insulation material for external walls, the raw material components are shown in Table 1 by weight parts.

[0036] Among them, the foaming agent is a protein foaming agent (refer to "Fine Chemical Industry" Volume 28, No. 1, January 2011 "Preparation and Performance of Rapeseed Meal Protein Concrete Foaming Agent" self-made).

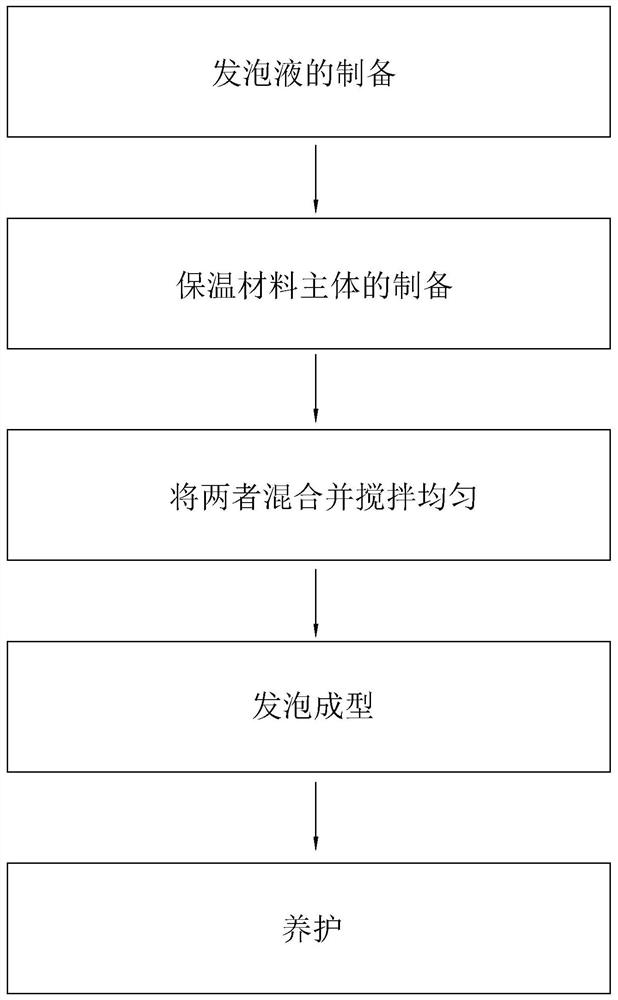

[0037] The preparation method of the external wall environmental protection thermal insulation material comprises the following steps:

[0038] Step 1, preparation of foaming liquid: mixing protein foaming agent, tea saponin and sucrose, stirring evenly;

[0039] Step 2, preparation of the main body of the insulation material: mix Portland cement, fly ash, glass fiber (6-8mm in length) and grapefruit peel fiber (4-6mm) evenly and fully, add appropriate amount of water and stir evenly to obtain cement slurry , while stirring, add the mixture of water-based epoxy resin (Dow Chemical DER916), water-based epoxy cu...

Embodiment 2

[0043]The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1.

Embodiment 3

[0045] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com