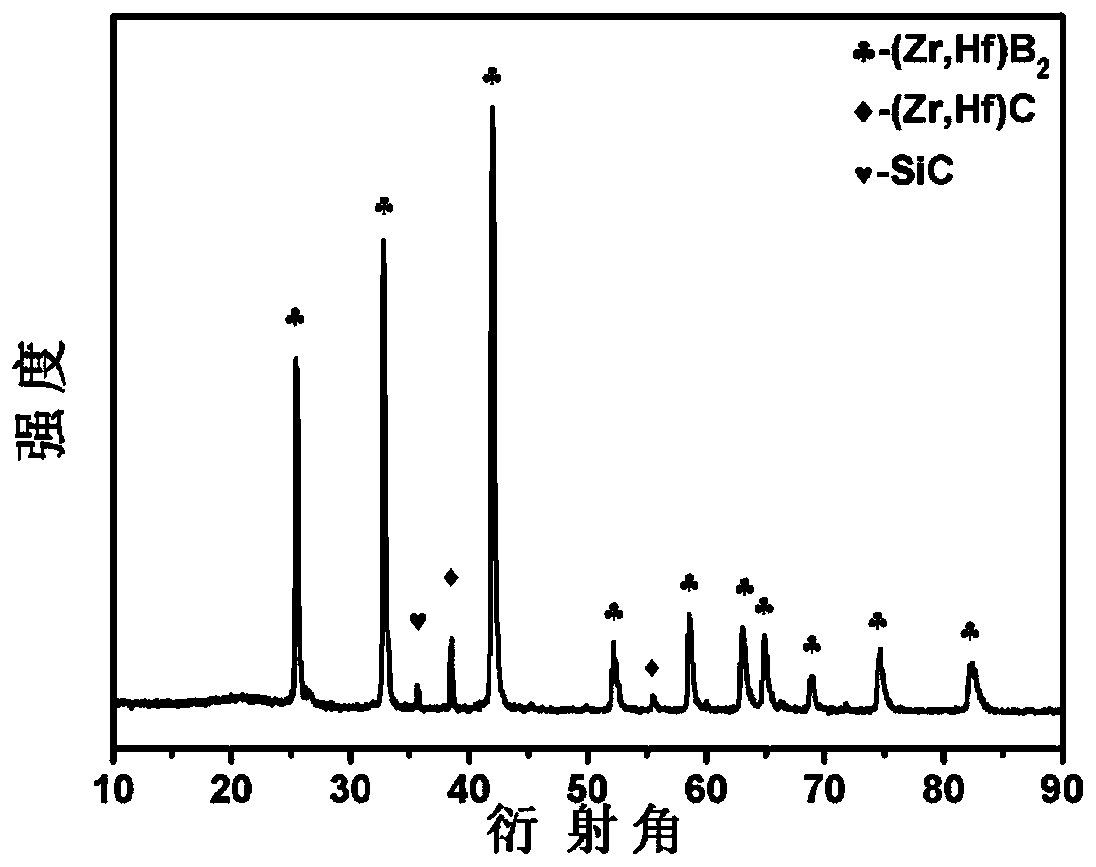

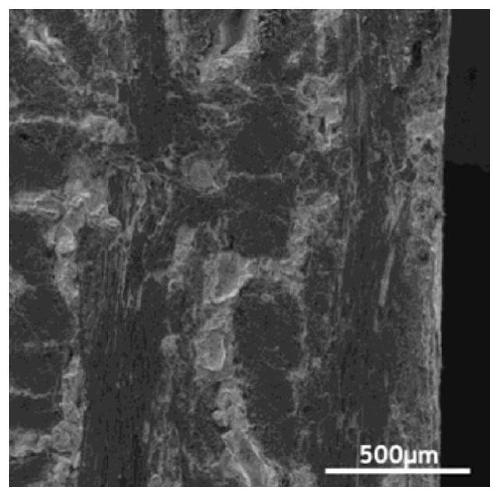

(Zr, Hf)B-SiC ceramic modified C/C composite material and preparation method thereof

A composite material and modification technology, applied in the field of C/C composite materials, can solve the problems of reduced ablation resistance, easy loss, poor bonding strength, etc., and achieve the effect of wide operating temperature range, good bonding, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A (Zr, Hf) B-SiC ceramic modified C / C composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0039] (1) In an argon atmosphere, the density is 1.1 ~ 1.2g / cm 3 Put the C / C composite material into a carbonization furnace, raise the temperature to 2000-2150°C at a rate of 5-15°C / min, keep it warm for 0.5-1h, and cool naturally to obtain a high-temperature treated C / C composite material.

[0040] (2) according to zirconium powder: hafnium powder material molar ratio is 1: 0.25~0.5, described zirconium powder and described hafnium powder are mixed, obtain compound I; Described compound I is inserted in planetary ball mill, Under the condition that the rotational speed is 400-500r / min and the pressure in the ball mill tank is 500-1000Pa, ball mill for 20-24h and sieve to obtain the zirconium-hafnium alloy powder with particle size≤48μm.

[0041] (3) According to the C / C composite material treated at high temperature: t...

Embodiment 2

[0045] A (Zr, Hf) B-SiC ceramic modified C / C composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0046] (1) In an argon atmosphere, the density is 1.15 ~ 1.25g / cm 3 Put the C / C composite material into a carbonization furnace, raise the temperature to 2150-2250°C at a rate of 5-15°C / min, keep it warm for 1-1.5h, and cool naturally to obtain a high-temperature treated C / C composite material.

[0047] (2) according to zirconium powder: hafnium powder material molar ratio is 1: 0.5~0.75, described zirconium powder and described hafnium powder are mixed, obtain compound I; Described compound I is inserted in planetary ball mill, Under the condition that the rotational speed is 450-550r / min and the pressure in the ball mill tank is 500-1000Pa, ball mill for 24-26 hours and sieve to obtain zirconium-hafnium alloy powder with a particle size of ≤48 μm.

[0048] (3) According to the C / C composite material treated at high temp...

Embodiment 3

[0052] A (Zr, Hf) B-SiC ceramic modified C / C composite material and a preparation method thereof. The preparation method described in this embodiment is:

[0053] (1) In an argon atmosphere, the density is 1.2 ~ 1.3g / cm 3 Put the C / C composite material into a carbonization furnace, raise the temperature to 2250-2400°C at a rate of 5-15°C / min, keep it warm for 1.5-2h, and cool naturally to obtain a high-temperature treated C / C composite material.

[0054] (2) according to zirconium powder: hafnium powder material molar ratio is 1: 0.75~1, described zirconium powder and described hafnium powder are mixed, obtain compound I; Described compound I is inserted in planetary ball mill, Under the condition that the rotational speed is 500-600r / min and the pressure in the ball mill tank is 500-1000Pa, ball mill for 26-30h and sieve to obtain the zirconium-hafnium alloy powder with particle size≤48μm.

[0055] (3) According to the C / C composite material treated at high temperature: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com