A kind of preparation method of waterborne two-component system acrylic resin with interpenetrating network structure

An interpenetrating network structure, acrylic resin technology, applied in the polymer field, can solve the problems of low adhesion, insufficient hardness, insufficient chemical resistance, and inability to meet the hardness development, achieve good chemical resistance, promote comprehensive water-based, fast The effect of hardness development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

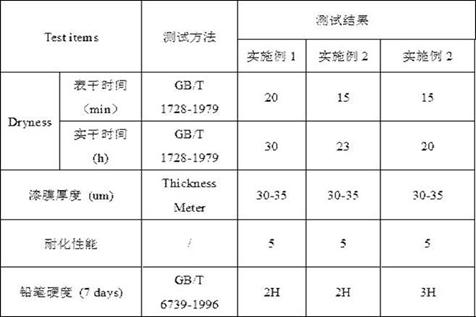

Examples

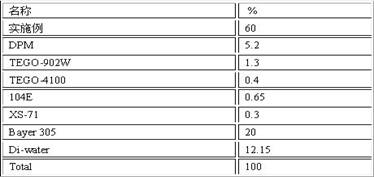

Embodiment 1

[0026] Take by weighing cobalt oxalate and methacrylic acid according to the proportioning ratio of 10%:90% of cobalt oxalate and methacrylic acid molar percentage, then both are put into reaction bottle, at 160 o C for 1 hour, adding copper oxide as a catalyst during the reaction. After the reaction is completed, it is confirmed by FT-IR and cooled to room temperature as a cross-linked network intermediate for later use

[0027] According to the molar percentage of methyl methacrylate, styrene, butyl acrylate, butyl methacrylate, isooctyl acrylate, hydroxyethyl methacrylate, mercaptopropionic acid is 20%:14%:10%:25% :25%:5%:1%, stir evenly, then add deionized water to make it into an aqueous solution with a solid content of 40%, add 2% ethylene glycol dimethacrylate, 1% sodium sulfite, and react at 80°C for 1 hours and keep warm for 1 hour, then cool down to 50°C

[0028] Add 10% of the above-mentioned synthetic cross-linked network intermediate, and continue to add 20%: 30...

Embodiment 2

[0032] Take cobalt oxalate and methacrylic acid according to the proportioning ratio of 20%:80% according to cobalt oxalate and methacrylic acid molar percentage, then both are put into reaction bottle, at 160 o C for 1 hour, and copper oxide needs to be added as a catalyst during the reaction. After the reaction is completed, it is confirmed by FT-IR and cooled to room temperature as a cross-linked network intermediate for later use

[0033]According to the molar percentage of methyl methacrylate, styrene, butyl acrylate, butyl methacrylate, isooctyl acrylate, hydroxyethyl methacrylate, and mercaptopropionic acid is 20%:14%:10%:25% :25%:5%:1%, stir evenly, then add deionized water to make it an aqueous solution with a solid content of 40%, add 2% ethylene glycol dimethacrylate, 1% sodium sulfite, and react at 80°C for 1 hours and keep warm for 1 hour, then cool down to 50°C

[0034] Add 10% of the above-mentioned synthetic cross-linked network intermediate, and continue to ...

Embodiment 3

[0038] Take by weighing cobalt oxalate and methacrylic acid according to the proportioning ratio of 10%:90% of cobalt oxalate and methacrylic acid molar percentage, then both are put into reaction bottle, at 160 o C for 1 hour, and copper oxide needs to be added as a catalyst during the reaction. After the reaction is completed, it is confirmed by FT-IR and cooled to room temperature as a cross-linked network intermediate for later use

[0039] According to the molar percentage of methyl methacrylate, styrene, butyl acrylate, butyl methacrylate, isooctyl acrylate, hydroxyethyl methacrylate, and mercaptopropionic acid is 20%:14%:10%:25% :25%:5%:1%, stir evenly, then add deionized water to make it solid and 40% aqueous solution, add 3% ethylene glycol dimethacrylate, 1% sodium sulfite, react at 80°C 1 hour and keep warm for 1 hour, then cool down to 50°C

[0040] Add 20% of the above-mentioned synthetic cross-linked network intermediate, and continue to add 20%: 30%: 10%: 30%:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com