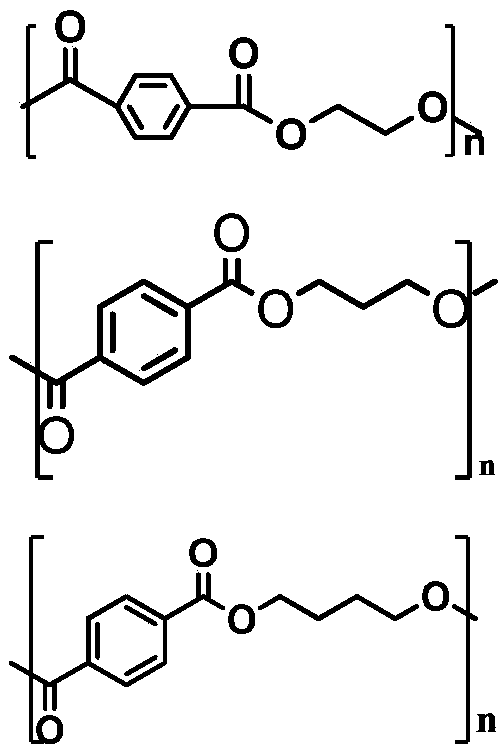

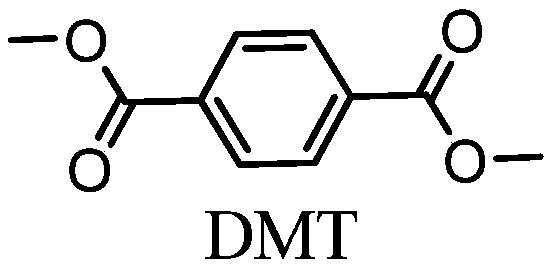

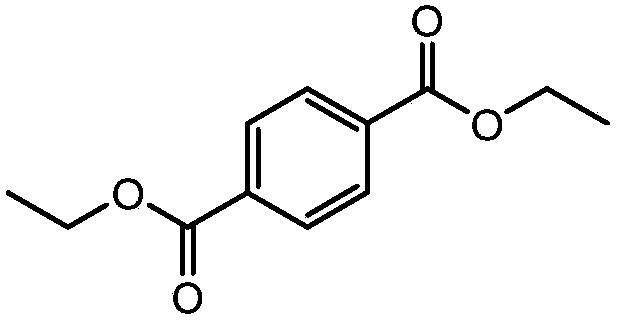

Method for converting PET, PTT and PBT products into cyclo-hydrocarbons in aviation kerosene range

A technology for aviation kerosene and manufactured products, applied in the petroleum industry, biological raw materials, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of occupying resources, wasting the recycling value of waste plastics, etc., to solve environmental problems, solve energy problems, substrates Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] 1. Preparation of catalyst:

[0029] The hydrogenation catalyst is prepared by equal-volume impregnation: mix a certain amount of metal solution and carrier evenly, then let it stand at room temperature for 4-12 hours, then dry it at 60-120°C for 4-12 hours, and then dry it at 200-600°C Calcination at lower temperature for 1-6 hours, reduction in hydrogen atmosphere at 100-400°C for 1-6 hours, and finally in 1% O by volume ratio 2 / N 2 passivation under the mixed atmosphere for 4h. Examples see the table below

[0030] The hydrodeoxygenation catalyst is prepared by co-impregnation: mix a certain amount of various metal solutions and the carrier evenly, then let it stand at room temperature for 4-12 hours, then dry it at 60-120°C for 4-12 hours, and then dry it at 200- Calcined at 600°C for 1-6h, reduced at 100-400°C under hydrogen atmosphere for 1-6h, and finally in 1% O by volume 2 / N 2 passivation under the mixed atmosphere for 4h. Examples are shown in the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com