Method for preparing thymidine by immobilized Escherichia coli

A technology of Escherichia coli and thymidine, which is applied in the field of biocatalysis, can solve the problem of low yield of thymidine in bacteria, and achieve the effects of large-scale production under reaction conditions, improved tolerance, and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preparing thymidine by immobilized Escherichia coli in this embodiment has the following steps:

[0025] (1) First, soak 3g of polyvinyl alcohol (PVA) in 50ml of distilled water for 24h, then add 0.3g of carrageenan, and keep it at 110℃ for 30min to sterilize and fully dissolve the PVA. Cool the mixed solution to 45℃ and keep it warm for use .

[0026] (2) Put a ring of mature E. coli seeds (about 1×10 6 A) Inoculate in 30mL liquid culture medium, 30℃, 100r / min shaking culture for 28h, and the culture solution is placed in a sterile centrifuge tube; centrifuged at 3000r / min for 10min, then washed with sterile saline, centrifuged again to obtain Escherichia coli cell.

[0027] (3) Add 50 mg of E. coli cells obtained in step ② and 10 mg of sterilized ultra-fine activated carbon to the mixed solution of step ①, and after mixing, use a syringe to drip sterile saturated boric acid and KCI solution (the quality of KCl The fraction is 7%) for 36 h to obtain immobiliz...

example 2~ example 7

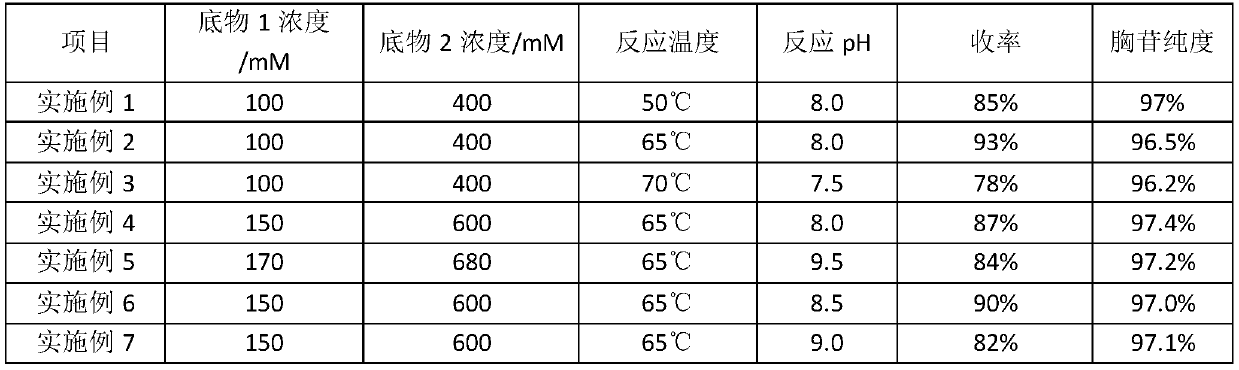

[0031] The methods and procedures of Examples 2-7 are basically the same as those of Example 1, and the differences are shown in Table 1. The substrate 1 is 2-deoxy-α-D-ribose-1-phosphate dicyclohexylamine salt, and the substrate 2 is Thymine:

[0032] Table 1

[0033]

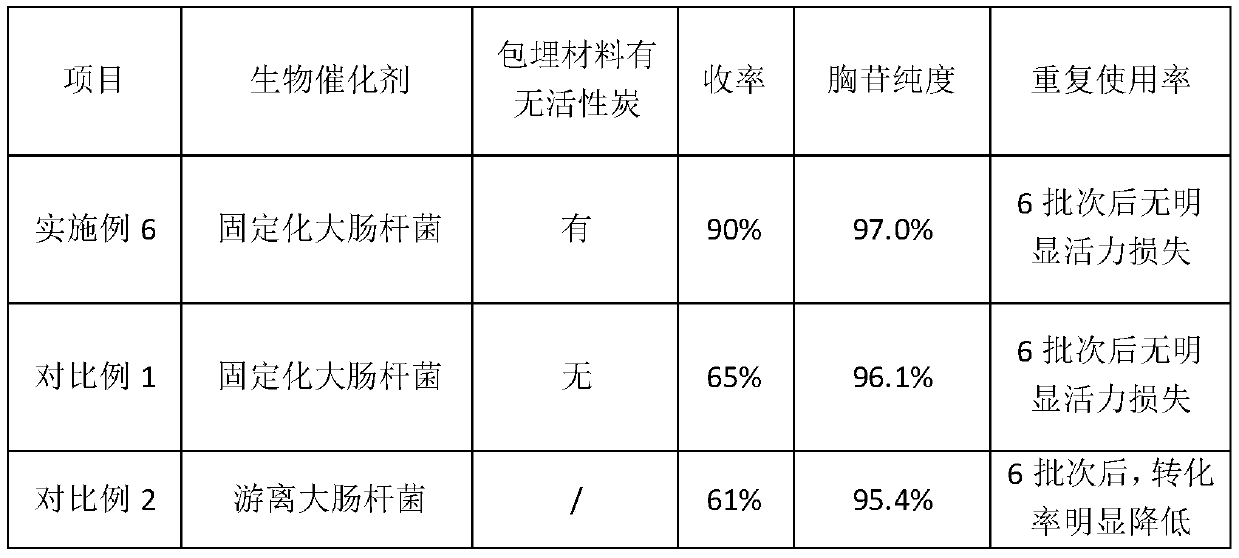

[0034] It can be seen from Table 1 that under the same other conditions, Example 6 has the best effect. The concentration of 2-deoxy-α-D-ribose-1-phosphate dicyclohexylamine salt is 150 mM, and the concentration of thymine is 150 mM. It is 600mM, the reaction temperature is 65°C, the thymidine yield reaches 90%, and the purity is 97.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com