Blue fluorescent polymer, blue fluorescent powder as well as preparation methods and applications of blue fluorescent polymer and blue fluorescent powder

A fluorescent polymer and polymer technology are applied in the fields of UV-to-blue light resin and its preparation, fluorescent fiber, fluorescent powder, and blue fluorescent polymer, which can solve the difficulty of biotoxic industrial application and the yield of non-conjugated polymer fluorescent agent. It has low biological toxicity and environmental pollution, good water solubility and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

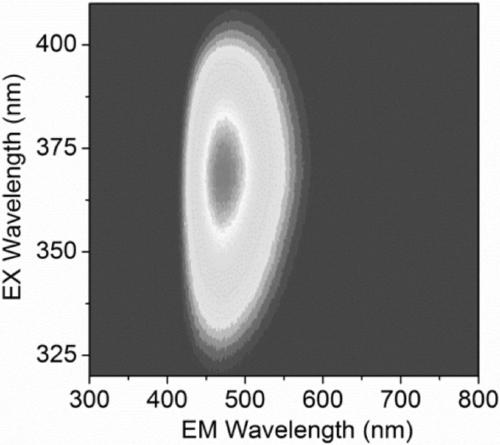

[0105] Weigh 25.6g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL) into 600mL of ethanol solution, stir and disperse; weigh 6.4g of sodium hydroxide into 600mL of deionized water for dissolution; The dispersion liquid was added dropwise to the aqueous solution of sodium hydroxide, while stirring until fully mixed, and then the mixed liquid was dried in an oven at 40° C. for 24 hours to remove ethanol to prepare an aqueous solution of the blue fluorescent polymer. This blue light fluorescent polymer aqueous solution shows very bright blue fluorescence under the irradiation of ultraviolet light, indicating that the blue light fluorescent polymer has high fluorescence intensity, and its three-dimensional fluorescence spectrum is as follows figure 1 As shown, the excitation range is 300-425nm, the emission range is 400-550nm, and the emission peak is mainly located in the blue light region between 430-520nm. The blue fluorescent polymer aqueous solution is dri...

Embodiment 2

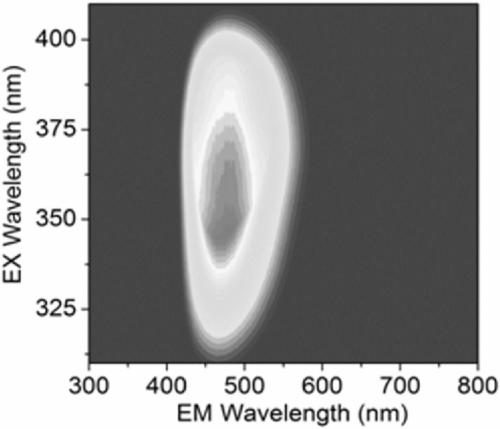

[0111] Weigh 12.8g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL, same as Example 1) into 200mL of ethanol solution, stir and disperse; weigh 1.9g of lithium hydroxide into 100mL of deionized water for dissolving Add the ethanol dispersion of MVL dropwise to the aqueous solution of lithium hydroxide, while stirring until fully mixed, then treat the mixed solution in a constant temperature oven at 40°C for 24 hours, remove the ethanol, and prepare an aqueous solution of blue light fluorescent polymer . This blue fluorescent polymer aqueous solution shows very bright blue fluorescence under the irradiation of ultraviolet light, indicating that the blue fluorescent polymer has high fluorescence intensity, and its three-dimensional fluorescence spectrum is as follows: figure 2 As shown, the excitation range is 300-425nm, the emission range is 400-550nm, and the emission peak is mainly located in the blue light region between 430-520nm. The blue fluorescent ...

Embodiment 3

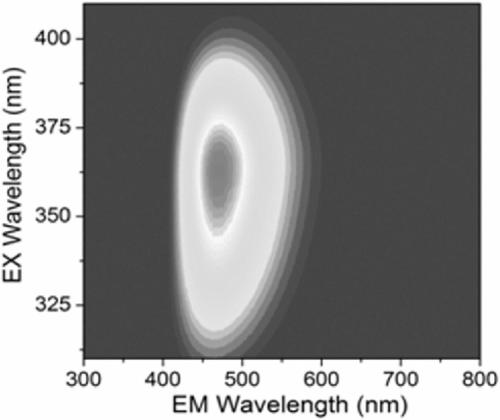

[0113] Weigh 12.8g of maleic anhydride-vinyl acetate linear alternating copolymer (MVL, the same as Example 1) and drop into 100mL of ethanol solution, stir and disperse; weigh 4.5g of potassium hydroxide into 300mL of deionized water for dissolving ; Add the ethanol dispersion of MVL dropwise to the aqueous solution of potassium hydroxide, while stirring until fully mixed, and then treat the mixed solution in a constant temperature oven at 40°C for 24 hours to remove the ethanol and prepare an aqueous solution of blue light fluorescent polymer . This blue fluorescent polymer aqueous solution shows very bright blue fluorescence under the irradiation of ultraviolet light, indicating that the blue fluorescent polymer has high fluorescence intensity, and its three-dimensional fluorescence spectrum is as follows: image 3As shown, the excitation range is 300-425nm, the emission range is 400-550nm, and the emission peak is mainly located in the blue light region between 430-520nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com