A cracking and desulfurization combined method and device and combined process of catalytic cracking and adsorption desulfurization

A catalytic cracking and desulfurization catalyst technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as the inability to meet clean fuel quality standards, achieve high stability, reduce separation costs, and improve gasoline yields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

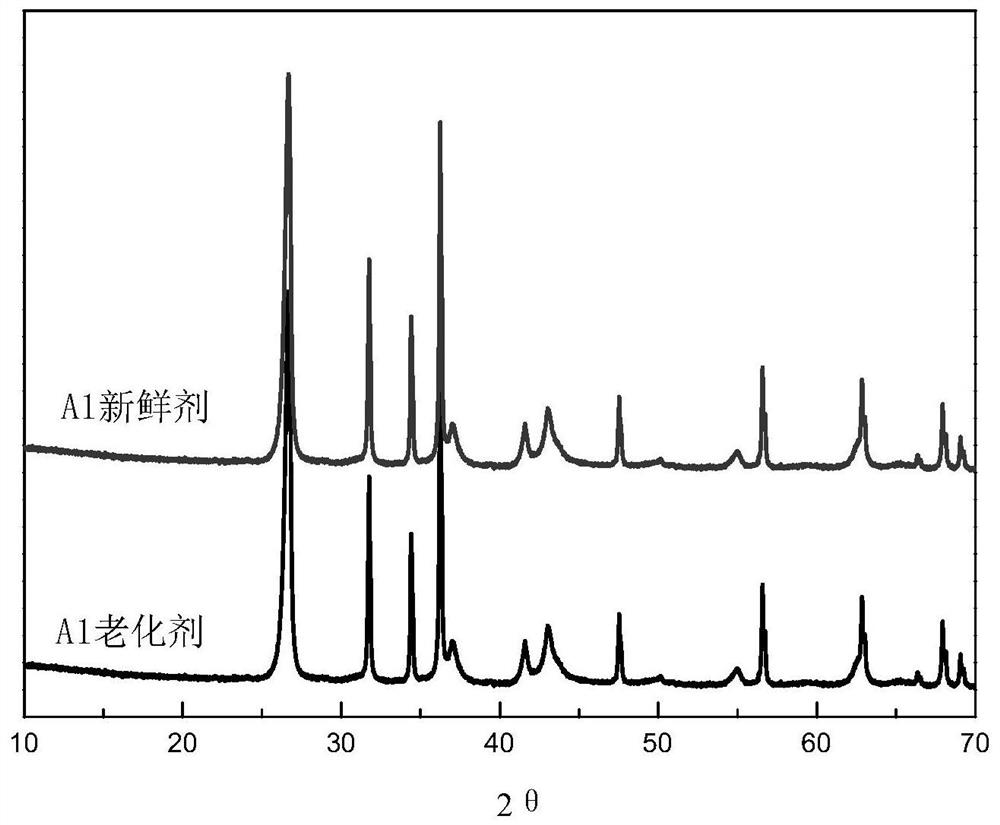

[0074] In one embodiment, the hydrocarbon oil desulfurization catalyst contains boron nitride, which has desulfurization and dehydrogenation properties and can improve the wear resistance of the catalyst. Reactions such as dehydrogenation and aromatization of naphthenic hydrocarbons generate hydrogen while generating high-octane aromatic components, reducing the consumption of hydrogen supply in the hydrocarbon oil desulfurization process, reducing the operation and application costs of the process, and the desulfurized gasoline produced. Quality has also been improved. Compared with desulfurization catalysts that do not use boron nitride, they have higher stability.

[0075] According to the present invention, the hydrocarbon oil desulfurization catalyst preferably contains 5-40% by weight of boron nitride, more preferably contains 12-25% by weight of boron nitride. According to the present invention, the hydrocarbon oil desulfurization catalyst contains the boron nitride, a...

Embodiment 1

[0110] 1. Preparation of hydrocarbon oil desulfurization catalyst

[0111] 4.43kg of zinc oxide powder (Headhorse company, purity 99.7% by weight) was mixed with 6.57kg of deionized water, and stirred for 30 minutes to obtain a mixed slurry of zinc oxide;

[0112] Take 1.81kg of pseudo-boehmite (Sinopec Catalyst Nanjing Branch, containing 1.36kg on a dry basis) and 2.4kg of hexagonal boron nitride (purity>99.0%, Qinhuangdao Yinuo High-tech Material Development Co., Ltd.) and stir and mix, then add After mixing 4.6kg of deionized water evenly to form a slurry, add 360ml of 30% by weight hydrochloric acid (chemically pure, produced by Beijing Chemical Factory) to make the slurry pH = 2.1, stir and acidify for 1 hour, then heat up to 80°C for aging for 2 hours, and then add zinc oxide The mixed slurry was mixed and stirred for 1 h to obtain a carrier slurry with a pH value of 3.5;

[0113] The resulting carrier slurry was used in Niro Bowen Nozzle Tower TM The model spray dryer...

Embodiment 2

[0129] 1. Preparation of hydrocarbon oil desulfurization catalyst

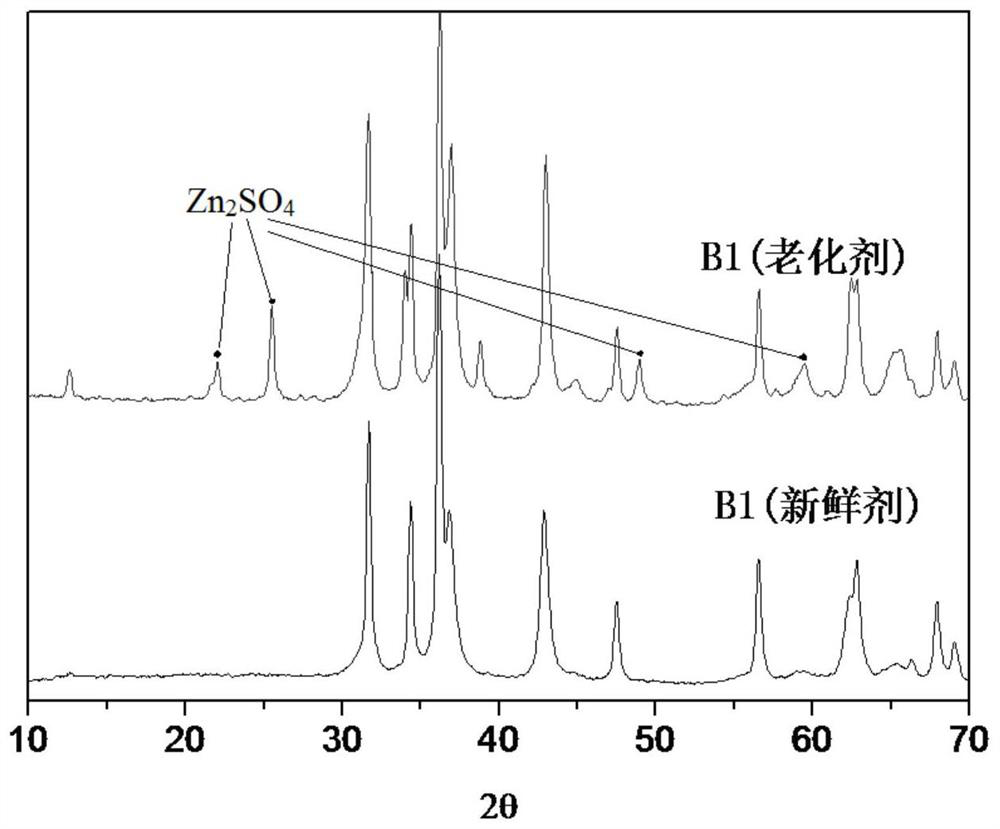

[0130] 3.21kg of tin tetrachloride (SnCl 4 ·5H 2 (2, Alfa company, 99%) slowly add the deionized water of 4.6kg, and add the nitric acid solution of 5% by weight of 4.6kg, stir slowly to avoid tin oxide crystallization, obtain colorless and transparent tin sol pH=2.1; Add 1.60 kg hexagonal boron nitride (purity>99.0%, Qinhuangdao Yinuo High-tech Material Development Co., Ltd.) was stirred and mixed, then 8.2 kg of deionized water was added and mixed evenly to form a slurry, and then 260 ml of 30% by weight hydrochloric acid was added to make the slurry pH=1.9 , stirred and acidified for 1 hour, then heated to 80°C for 2 hours of aging. After the temperature dropped, 5.52 kg of zinc oxide powder was added, and stirred for 1 hour to obtain a carrier slurry with a pH value of 3.5.

[0131] Referring to the method of Example 1, the catalyst carrier slurry was spray-dried and shaped, and the active component nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com