Silicon-based composite negative electrode material and preparation method thereof and energy storage device

A technology of silicon-based materials and negative electrode materials, applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve the problems of fast consumption of electrolyte, structural damage of electrode materials, pulverization, etc., and achieve improved negative electrode cycle performance and long life Safety performance, effect of preventing corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Correspondingly, the embodiment of the present invention also provides a method for preparing a silicon-based composite negative electrode material, including the following steps:

[0042] S10, taking a silicon-based material, and forming a fast ion conductor layer on the surface of the silicon-based material;

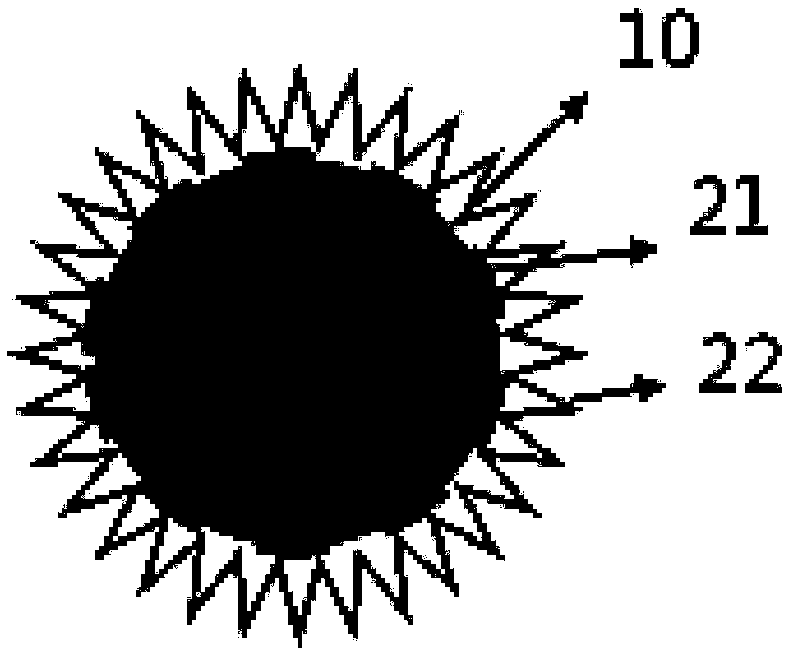

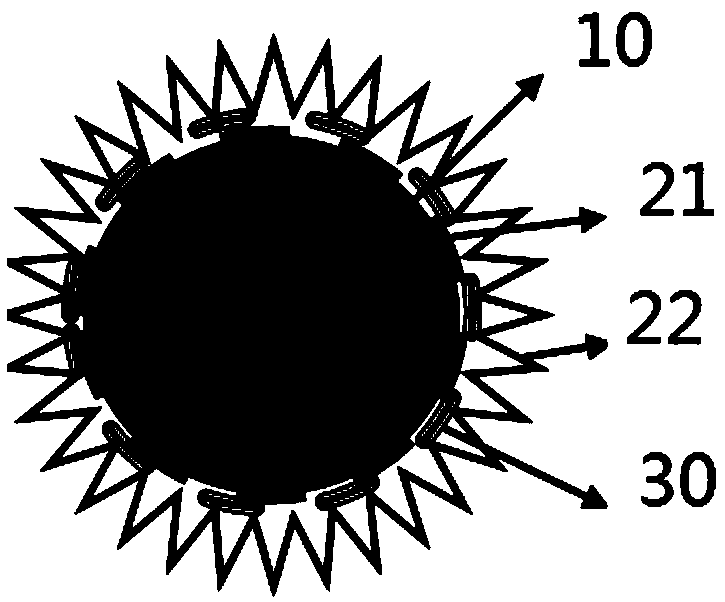

[0043] S20, forming a fluorine-containing carbon material layer on the surface of the fast ion conductor layer to obtain a silicon-based composite negative electrode material, the silicon-based composite negative electrode material comprising a silicon-based material core and a coating formed on the surface of the silicon-based material core core layer, the cladding layer includes a fast ion conductor layer and a fluorocarbon material layer, the fluorocarbon material layer is formed on the surface of the fast ion conductor layer, and the fast ion conductor layer is formed on the silicon-based material core The surface is located between the silicon-based materia...

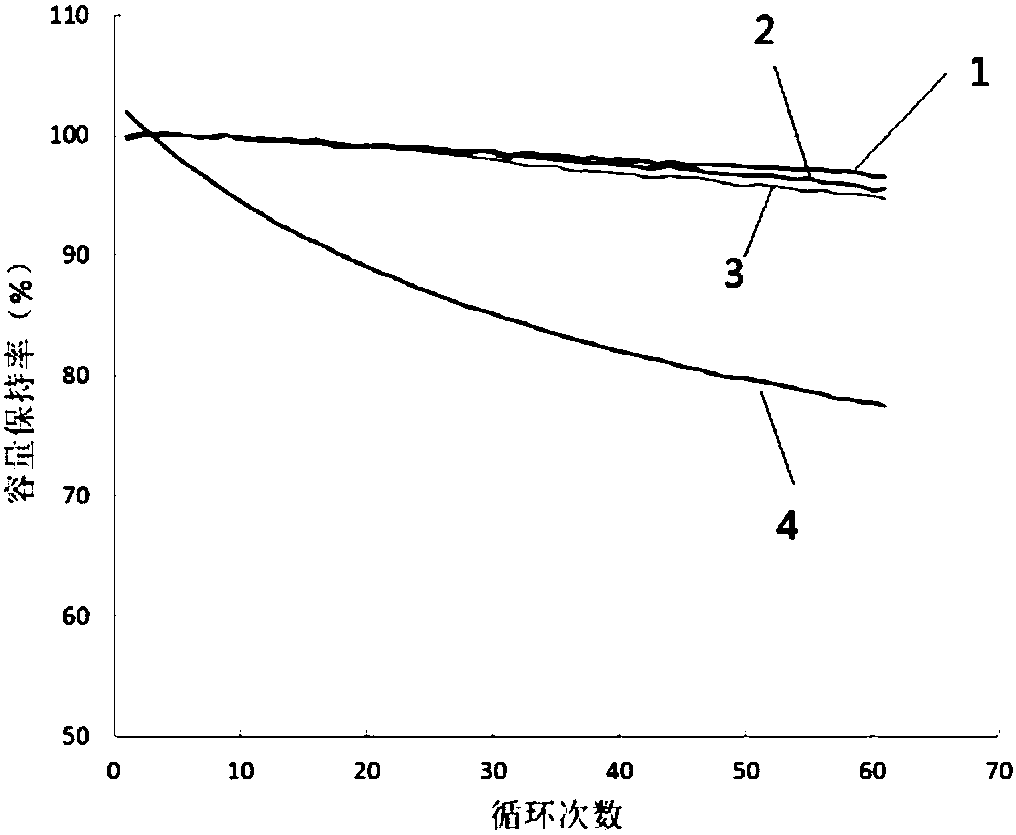

Embodiment 1

[0054] A method for preparing a silicon-based composite negative electrode material, comprising the steps of:

[0055] S101, Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Fabrication of Coated Silicon (Si@LATP) Materials

[0056] Add 10 g of commercial nano-silicon (median particle size D50 is 80nm-150nm) into 100mL deionized water, ultrasonically disperse, and then sequentially add lithium acetate (Li(CH 3 COO)·2H 2 O), aluminum nitrate (Al(NO) with a final concentration of 0.6mol / L 3 )·9H 2 O) and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), magnetically stirred at room temperature until completely dissolved. Add 5 mL of acetylacetone to the mixed salt solution, stir for 15 min, drop in stoichiometric ratio of 0.34 mol / L butyl titanate drop by drop, continue to stir for 2 h to obtain Si@LATP sol, stand and mature for 24 h, and place the gel in Vacuum dry at 100°C for 6h, then raise to 700°C at 5°C / min, and keep for 2h to obtain the silicon material Si@LATP coated with LATP o...

Embodiment 2

[0064] A method for preparing a silicon-based composite negative electrode material, comprising the steps of:

[0065] S101, Li 7 La 3 Zr 2 o 12 Preparation of Coated SiO(SiO@LLZO) Material

[0066] Take Li 2 CO 3 , La 2 o 3 and ZrO(NO 3 ) 2 ·6H 2 O, according to the molar ratio of 7.7:3:2 feeding and dissolving in the aqueous solution, adjust the pH~7 to obtain Li 7 La 3 Zr 2 o 12 Precursor solution: Disperse commercial SiO samples (median particle size D50 of 1 μm-5 μm) in LLZO precursor solution, mix well, filter, dry the obtained solid, and sinter at 850°C for 5-8h (under argon atmosphere ), get Li 7 La 3 Zr 2 o 12 Coated SiO material SiO@LLZO.

[0067] S102. Preparation of graphene-coated SiO@LLZO (SiO@LLZO@graphene) material

[0068] Disperse SiO@LLZO on the quartz substrate, transfer it to the furnace, pass in a hydrogen-argon mixture gas, raise it to 1000°C at a rate of 20°C / min, and maintain it for 20 minutes; then stop the flow of protective gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com