Preparation method of high-light transmission electromagnetic shielding film

A technology of electromagnetic shielding and transparent conductive film, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor shielding effect, reduced electromagnetic shielding performance, gap leakage, etc., to facilitate large-scale industrial production and improve electromagnetic Effect of shielding performance and high electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

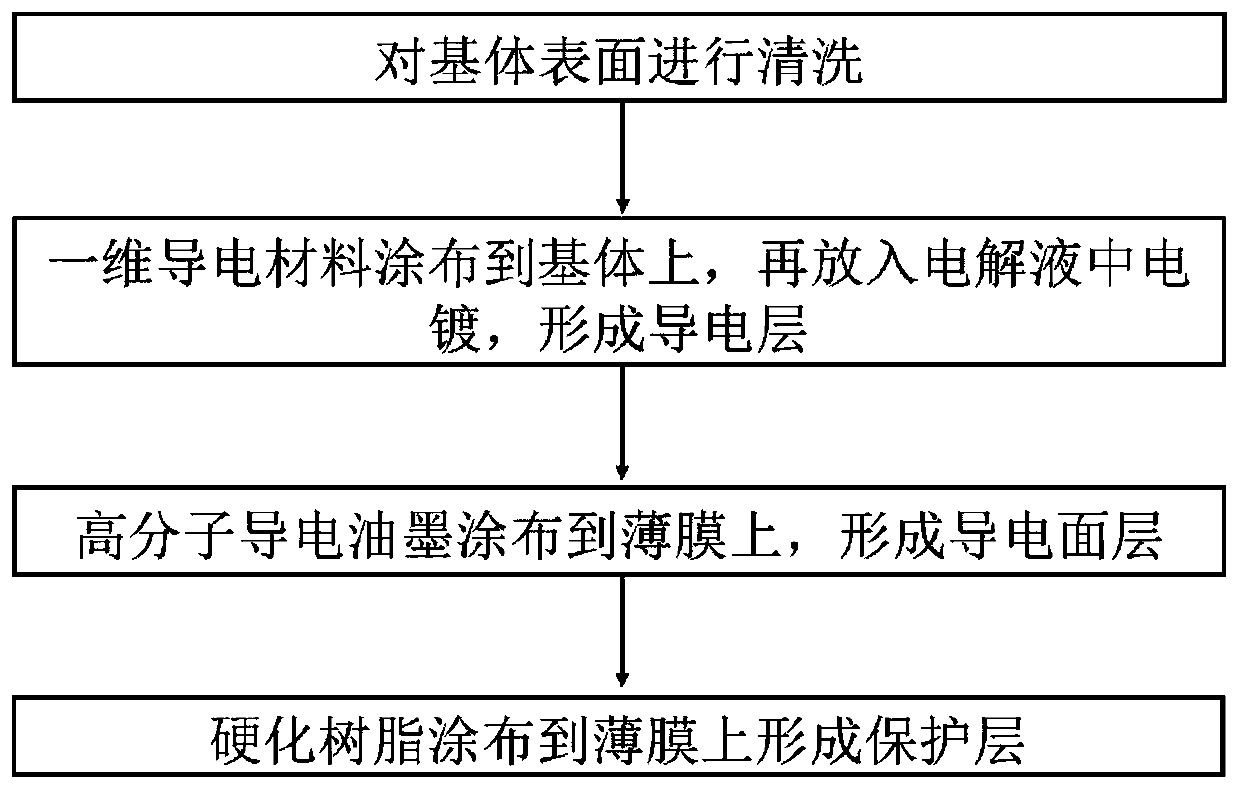

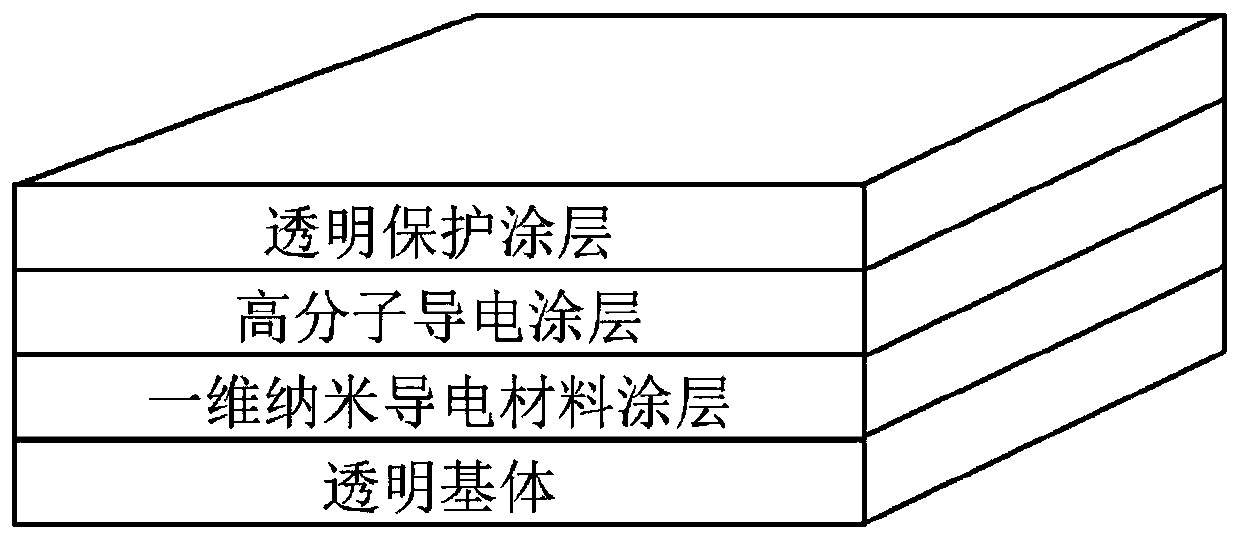

[0031] (1) Put the polyethylene terephthalate base body into ethanol for 10 minutes and sonicate for 10 minutes, and the ultrasonic power is 100W to remove impurities on the surface of the base body.

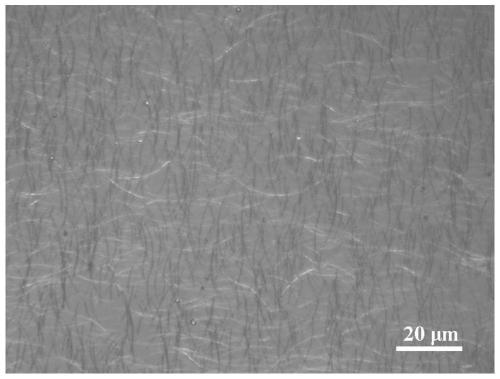

[0032] (2) Disperse the silver nanowires in the polyurethane aqueous solution, the solid content of the silver nanowires is 1.5‰, and the solid content of the polyurethane is 2‰. Take 1mL of the mixed solution and add it dropwise on the surface of the transparent substrate, and use a wire rod to evenly coat the liquid on the surface of the transparent substrate. Put the transparent substrate in an oven at 60°C and heat for 20 minutes.

[0033] (3) Put the cooled transparent substrate into a solution containing silver nitrate at a concentration of 1 mM, apply a voltage of 5 V, and electroplate for 10 min. Then ultrasonicated in ethanol for 5 minutes, the ultrasonic power was 100W to remove the residual substances on the surface. After the ultrasound is finished, put it in an ov...

Embodiment 2

[0038] (1) Put the polyethylene naphthalate base body into ethanol and ultrasonicate for 30 minutes with an ultrasonic power of 200W to remove impurities on the surface of the base body.

[0039] (2) Disperse the nano-silver wires in polyacrylic acid resin, the solid content of the nano-silver wires is 2‰, and the solid content of the polyacrylic resin is 2‰. Take 1mL of the mixed solution and add it dropwise on the surface of the transparent substrate, and use a wire rod to evenly coat the liquid on the surface of the transparent substrate. Put the transparent substrate in an oven at 60°C and heat for 10 minutes.

[0040] (3) Put the cooled transparent substrate into an aqueous solution containing silver nitrate at a concentration of 2mM, apply a voltage of 12V, and electroplate for 3min. Then ultrasonicate in ethanol for 5 minutes, the ultrasonic power is 200W to remove the remaining substances on the surface. After the ultrasound is finished, put it in an oven at 150°C an...

Embodiment 3

[0044] (1) Put the polymethyl methacrylate substrate into ethanol and ultrasonicate for 20 minutes with an ultrasonic power of 200W to remove impurities on the surface of the substrate.

[0045] (2) Disperse the silver nanowires in an aqueous solution of epoxy resin, the solid content of the silver nanowires is 1.5‰, and the solid content of the epoxy resin is 2‰. Take 1mL of the mixed solution and add it dropwise on the surface of the transparent substrate, and use a wire rod to evenly coat the liquid on the surface of the transparent substrate. Put the transparent substrate in an oven at 150°C and heat for 30 minutes.

[0046] (3) Put the cooled transparent substrate into an aqueous solution containing silver nitrate at a concentration of 10 mM, apply a voltage of 12 V, and electroplate for 3 minutes. Then ultrasonicate in ethanol for 5 minutes, the ultrasonic power is 200W to remove the remaining substances on the surface. After the ultrasound is finished, put it in an ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com