Titanium-based perovskite ceramic oxygen-permeable membrane with no cobalt or iron and preparation method and application thereof

A perovskite-type, oxygen-permeable membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems such as poor chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

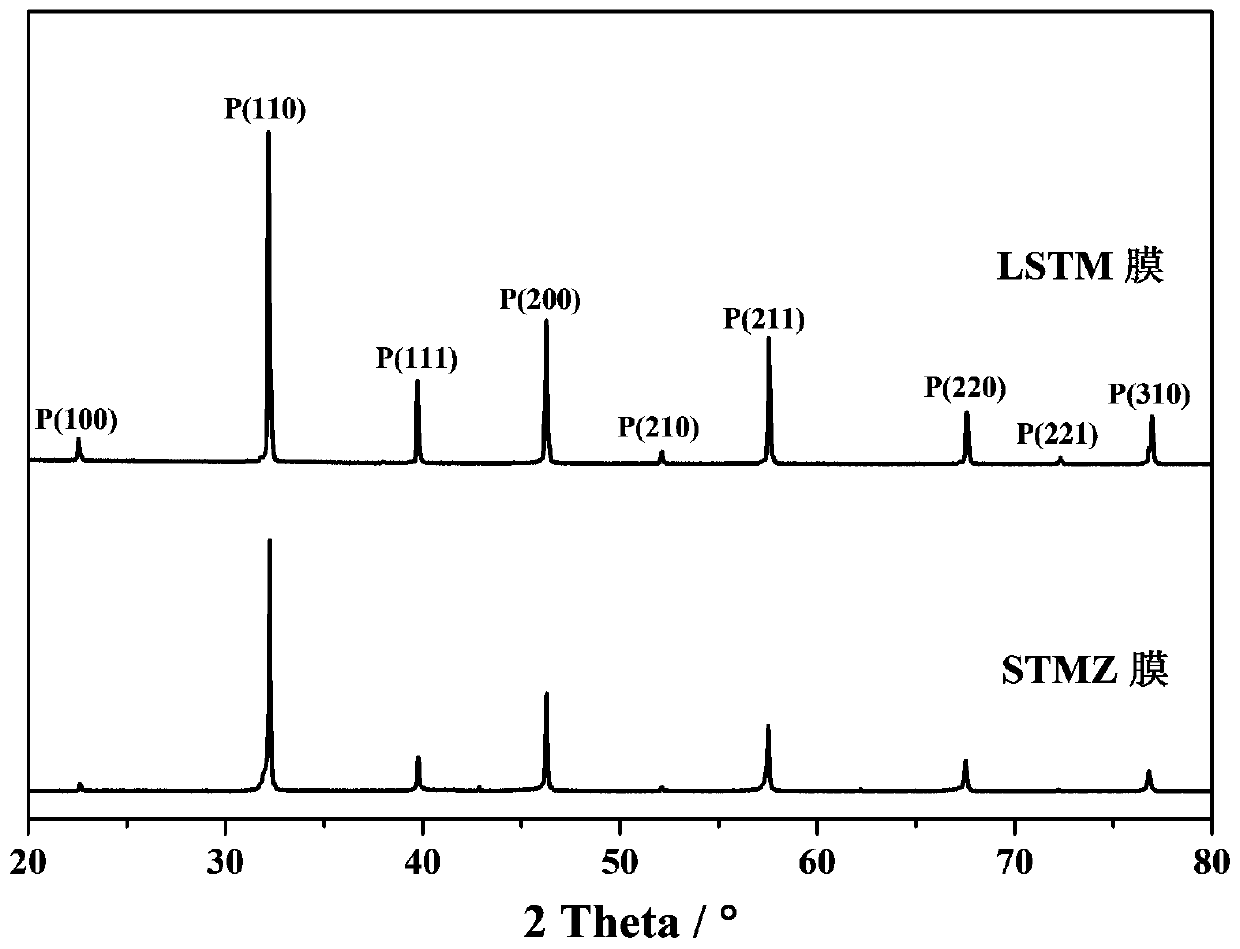

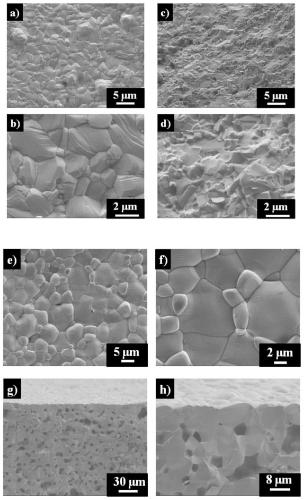

[0032] SrTi 0.8 Mg 0.15 Zr 0.05 o 3-δ (STMZ) Oxygen Permeable Membrane Preparation:

[0033] According to the stoichiometric ratio of the above materials, Sr(NO 3 ) 2 , Mg(NO 3 ) 2 and ZrO(NO 3 ) 2 Dissolve in water respectively, and then add citric acid and ethylenediaminetetraacetic acid to the mixture according to the molar ratio of citric acid, ethylenediaminetetraacetic acid and metal ion at a ratio of 1.5:1:1, and then add appropriate amount of ammonia water to adjust the solution At a pH of 9, a nitrate solution was obtained. Then mix tetrabutyl titanate with the mixed solution according to the stoichiometric ratio of STMZ; stir and mix until there is no gel and precipitation, and a stable solution is obtained. Wherein the mixed solution is mixed with equimolar lactic acid, absolute ethanol and glacial acetic acid.

[0034] Under the stirring condition of 500 rev / min, the precursor of STMZ was obtained after fully mixing the previously prepared nitrate soluti...

Embodiment 2

[0036] La 0.2 Sr 0.7 Ti 0.95 Mg 0.05 o 3-δ (LSTM) Oxygen Permeable Membrane Preparation:

[0037] According to the stoichiometric ratio of the above materials, La(NO 3 ) 3 , Sr(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolve in water respectively, and then add citric acid and ethylenediaminetetraacetic acid to the mixture with the molar ratio of citric acid, ethylenediaminetetraacetic acid and metal ion at a ratio of 1.5:1:1, and then add appropriate amount of ammonia water to adjust the pH of the solution A value of 9 yields a nitrate solution. Afterwards, tetrabutyl titanate was mixed with the mixed liquid according to the stoichiometric ratio of LSTM, and stirred and mixed uniformly until there was no gel and precipitation, and a stable solution was obtained. Among them, the mixed solution is a mixture of equimolar lactic acid, absolute ethanol and glacial acetic acid; under the stirring condition of 500 rpm, the nitrate solution and the stable solution prepared before are ful...

Embodiment 3

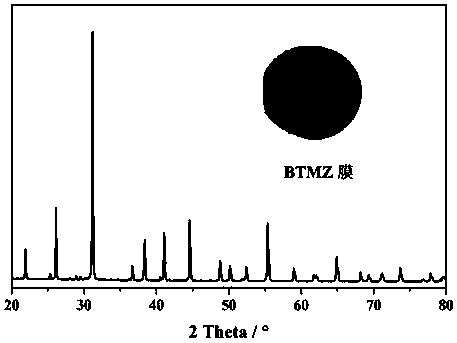

[0039] BaTi 0.85 Mg 0.1 Zr 0.05 o 3-δ (BTMZ) Oxygen Permeable Membrane Preparation:

[0040] According to the stoichiometric ratio of the above materials, Ba(NO 3 ) 2 , Mg(NO 3 ) 2 and ZrO(NO 3 ) 2 Dissolve in water respectively, and then add citric acid and ethylenediaminetetraacetic acid to the mixture according to the molar ratio of citric acid, ethylenediaminetetraacetic acid and metal ion at a ratio of 1.5:1:1, and then add appropriate amount of ammonia water to adjust the solution At a pH of 9, a nitrate solution was obtained. Then, tetrabutyl titanate was mixed with the mixed solution according to the stoichiometric ratio of BTMZ, wherein the mixed solution was mixed with equimolar lactic acid, absolute ethanol and glacial acetic acid, stirred and mixed until there was no gel and precipitation, and a stable solution was obtained.

[0041] Under the stirring condition of 500 rev / min, the precursor of BTMZ was obtained after fully mixing the previously prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com