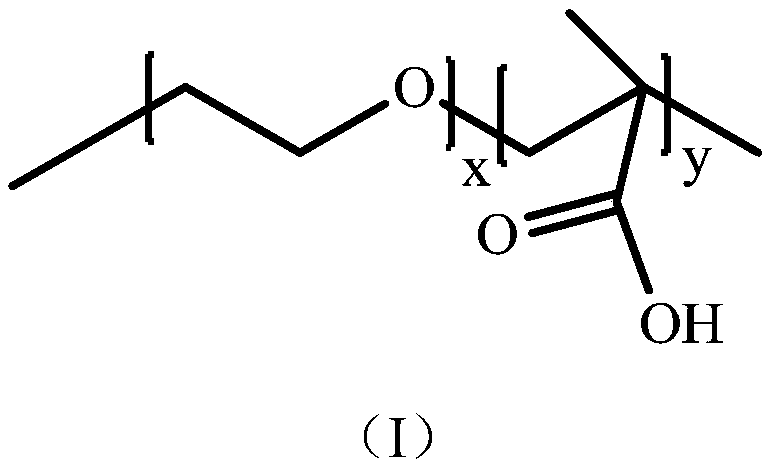

Oxirane-based polymer, preparation method thereof and application of polymer

A technology of oxirane and oxirane, which is applied in the field of oxirane polymers and its preparation, can solve the problems of harsh experimental conditions and complex synthesis routes, and achieve simple processing, easy-to-obtain reaction raw materials, The effect of cheap reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Synthesis of poly(ethylene oxide) 50 -co-tert-butyl methacrylate 50 )(P(EO 50 -co-BMA 50 )) random copolymer

[0023] Purified tert-butyl methacrylate (10 mmol, 1.42 g), tetrahydrofuran (5 mL), benzyl alcohol (0.1 mmol, 10.0 mg), and then ethylene oxide were added to a Slank flask equipped with a stirring bar. (10mmol, 0.44g), then "freeze vacuum-thaw" twice, thaw; put the slank bottle into the reaction bath at -40 ℃, add phosphazene base (0.1mmol, 100ul), react for 6h, and then It was moved to the reaction bath at 40°C and the reaction was continued for 18h. The reaction was terminated and n-hexane precipitated to give a white solid, which was dried in vacuo. Through nuclear magnetic analysis, it was found that the molar ratio of ethylene oxide and tert-butyl methacrylate in the obtained copolymer was basically the same as its charging ratio, and kept a relatively narrow molecular weight distribution, indicating that phosphazene base was used as the catalyst. ...

Embodiment 2

[0027] Synthetic P(EO 50 -co-BMA 50 ) random copolymer

[0028] Change the reaction solvent of embodiment 1 step (1) into toluene from tetrahydrofuran, and other implementation conditions and the synthesis of P(EO in Example 1) 50 -co-BMA 50 ) is the same as the random copolymer. Through the analysis of the polymer, the copolymer can also be successfully prepared by using toluene as the solvent.

Embodiment 3-6

[0030] Synthetic P(EO 50 -co-BMA 50 ) random copolymer

[0031] The initiator of embodiment 1 step (1) is changed from benzyl alcohol to ethylene glycol, butanediol, methyl alcohol or ethanol, and other implementation conditions and the synthesis of P(EO in Example 1) 50 -co-BMA 50 ) is the same as the random copolymer, through the analysis of the polymer, the copolymer can also be successfully prepared by using the above four alcohols as the initiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com