High-barrier functional PVA coating liquid as well as preparation method and application thereof

A functional, coating liquid technology, used in coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as inability to meet demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method for the high-barrier functional PVA coating solution described in the above technical solution, comprising the following steps:

[0034] Mix PVA, functional substances, processing aids and water to obtain a high-barrier functional PVA coating liquid.

[0035] In the present invention, the order of mixing is preferably to add functional substances into PVA first, and then add water and processing aids in sequence. The present invention has no special limitation on the mixing method, and conventional mixing methods in the field can be used, specifically, mechanical stirring.

[0036] In the present invention, after the sequential addition of water and processing aids is completed, water is preferably added to adjust the concentration of PVA in the PVA coating solution. In the present invention, the concentration of the PVA is preferably 2%-30%.

[0037] The present invention also provides the application of the hi...

Embodiment 1

[0040] The following components by weight were weighed to prepare a high-barrier functional PVA coating liquid, and the specific components by weight are shown in Table 1.

[0041] Component parts by weight of high barrier functional PVA coating solution in Table 1 Example 1

[0042] components

[0043] First add ginseng extract to PVA, add water during stirring, dissolve, add water-based polyurethane and ethanol in turn, and finally add water again, adjust the concentration of PVA to 2%, and prepare a high-barrier functional PVA coating liquid.

Embodiment 2

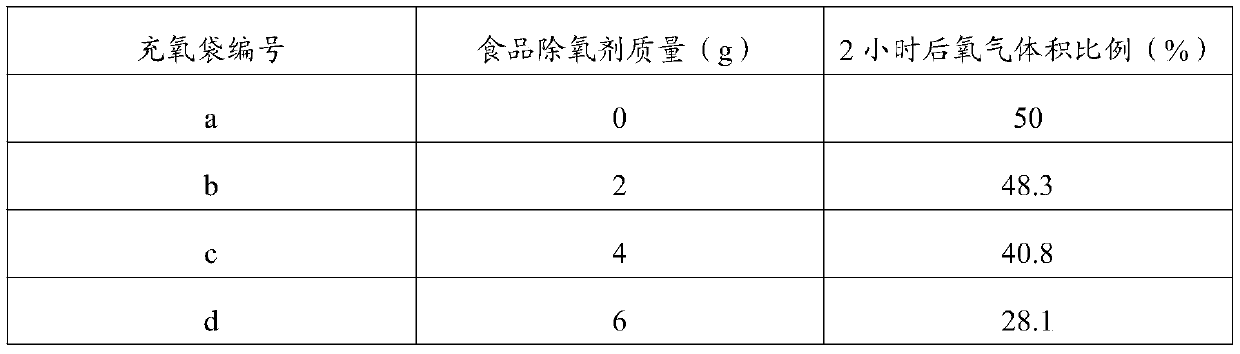

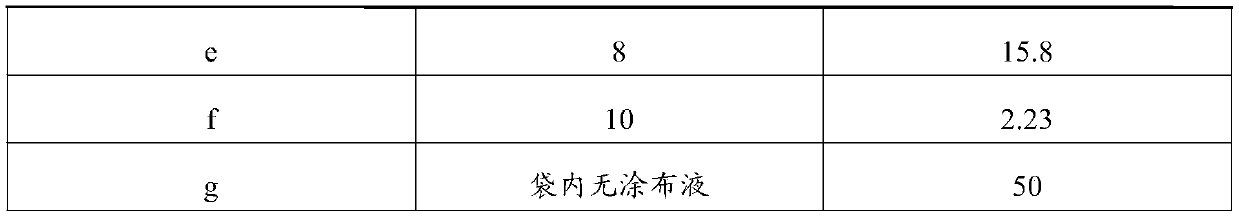

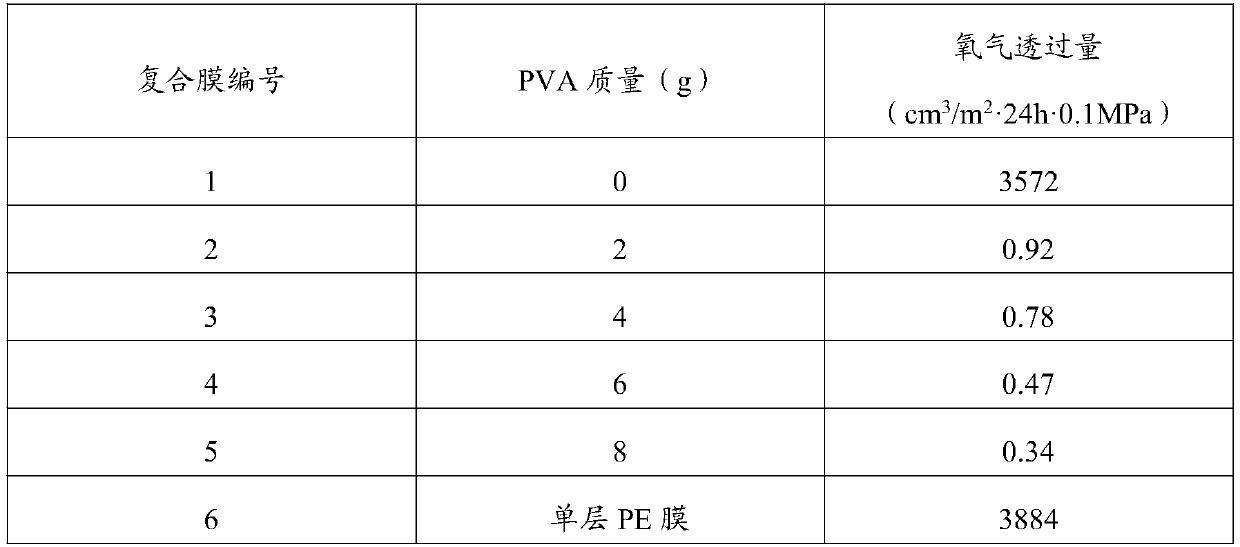

[0045] In order to investigate the anti-oxidation performance of the coating liquid, take the DPPH free radical scavenging function as the evaluation index, on the basis of the formula composition and preparation method of Example 1, keep other compositions unchanged, and set parallel The experimental group, experimental group settings and experimental results are shown in Table 2:

[0046] Table 2 The results of scavenging DPPH free radicals in high-barrier functional PVA coating solutions prepared by adding different functional substances

[0047] Coating solution number

[0048] As can be seen from Table 2, the DPPH free radical scavenging ability of the PVA coating solution without functional substances is only 1.31%, almost no anti-oxidation ability, and after adding functional substances, the scavenging ability of DPPH free radicals is greatly improved. Among them, except the DPPH free radical scavenging ability of the F coating liquid is 34.23%, the DPPH free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com