High-water-resistance and weather-resistance polarizer adhesive, polarizer and preparation method

A technology of water resistance and weather resistance, applied in the field of polarizers, can solve the problems of difficult control of borax gel, undisclosed water resistance, and limited application range, etc., and achieve the effects of reducing hydrophilicity, high weather resistance, and reducing the number of hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

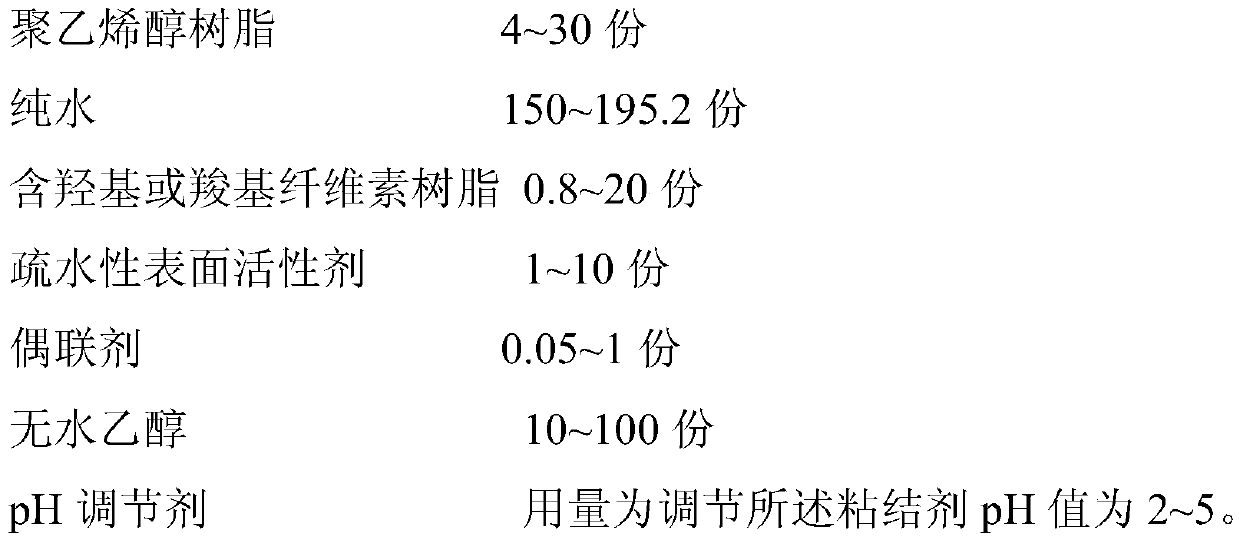

[0055] Preparation of high water resistance and high weather resistance adhesive: (1) Preparation of polyvinyl alcohol aqueous solution: Weigh 96 parts of pure water, add 4 parts of polyvinyl alcohol resin under stirring at 80 rpm, and pre-dissolve for 60 minutes to make polyvinyl alcohol resin Fully swell, heat up to 95°C, keep warm for 120min, cool down to room temperature, and obtain an aqueous solution of polyvinyl alcohol; (2) weigh 99.2 parts of pure water, add 0.8 parts of hydroxypropyl methylcellulose resin under stirring at 80 rpm, and make It is fully dissolved to obtain an aqueous solution of a crosslinking agent; (3) Weigh 1 part of stearic acid and 0.05 part of γ-aminopropyl triethoxysilane, and add them to 10 parts of absolute ethanol under stirring at 80 rpm to obtain a hydrophobic Surfactant alcohol solution; (4) under 80rpm stirring state, polyvinyl alcohol aqueous solution and crosslinking agent aqueous solution are mixed to obtain a mixed solution, and then t...

Embodiment 2

[0059] Preparation of high water resistance and high weather resistance adhesive: (1) Preparation of polyvinyl alcohol aqueous solution: Weigh 90 parts of pure water, add 10 parts of polyvinyl alcohol resin under stirring at 100 rpm, pre-dissolve for 45 minutes, and make polyvinyl alcohol resin Fully swell, heat up to 90°C, keep warm for 90min, cool down to room temperature, and obtain an aqueous solution of polyvinyl alcohol; (2) weigh 95 parts of pure water, add 5 parts of hydroxyethyl cellulose resin under stirring at 100 rpm, and make it fully (3) Weigh 3 parts of oleic acid and 0.8 parts of γ-methacryloxypropyltrimethoxysilane coupling agent, and add them to 10 parts of absolute ethanol under stirring at 100rpm , to obtain the hydrophobic surfactant alcohol solution; (4) under the 100rpm stirring state, the polyvinyl alcohol aqueous solution and the crosslinking agent aqueous solution are mixed to obtain a mixed solution, and then the hydrophobic surfactant alcohol solutio...

Embodiment 3

[0063] Preparation of high water resistance and high weather resistance adhesive: (1) Preparation of polyvinyl alcohol aqueous solution: Weigh 85 parts of pure water, stir at 90rpm, add 15 parts of polyvinyl alcohol resin, pre-dissolve for 30min, make polyvinyl alcohol resin Fully swell, heat up to 100°C, keep warm for 60min, cool down to room temperature, and obtain an aqueous solution of polyvinyl alcohol; (2) weigh 85 parts of pure water, add 15 parts of carboxymethylcellulose resin under stirring at 90rpm, and make it fully Dissolve to obtain cross-linking agent aqueous solution; (3) take by weighing 5 parts of lauric acid and 0.5 part of vinyltriethoxysilane coupling agent, join in 80 parts of dehydrated alcohol under stirring at 90rpm, obtain hydrophobic surfactant Alcohol solution; (4) under 90rpm stirring state, polyvinyl alcohol aqueous solution and crosslinking agent aqueous solution are mixed to obtain a mixed solution, and then the hydrophobic surfactant alcohol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com