Self-lubricating wear-resistant eutectic graphitic steel and preparation method thereof

A wear-resistant and self-lubricating technology, applied in the field of ferrous metal materials, can solve the problems of large damage to mechanical properties, continuity of split matrix tissue, and low reliability, and achieve the effect of superior sound absorption and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

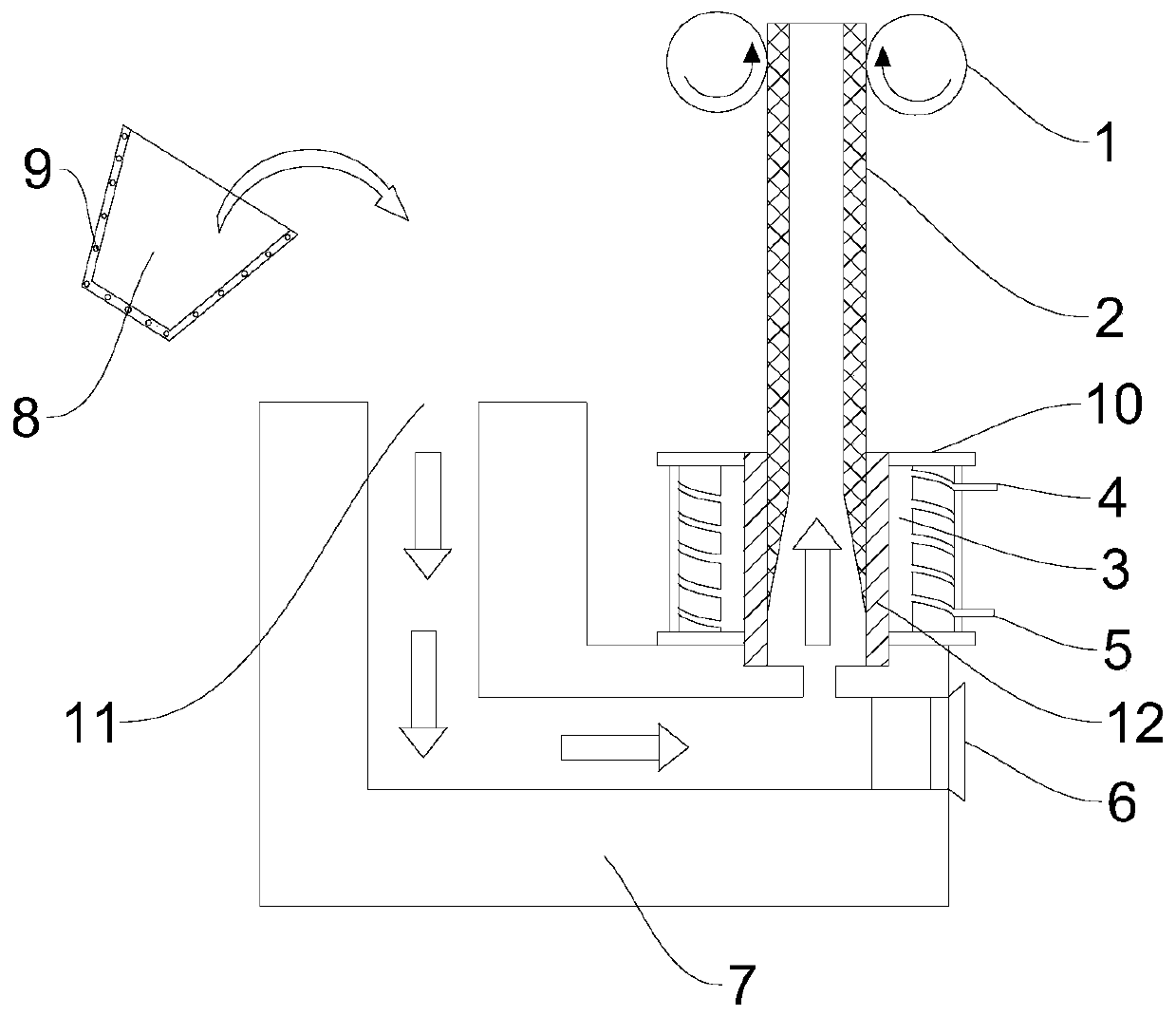

[0029] A method for preparing self-lubricating and wear-resistant eutectic graphite steel, comprising the steps of:

[0030] According to the mechanical properties (hardness, tensile strength, elongation, impact toughness, etc.) 10, QT550-6, QT600-5, etc.) and specifications, use empirical formulas to calculate the ratio of various materials (bread iron, scrap steel, recycled materials, various ferroalloys, etc.), and preset the molten iron after inoculation and ball After chemical treatment, its carbon equivalent will be in the range of eutectic composition (CE) or slightly lower than 0.05% of this composition; the preset composition material is melted into molten iron in an electric furnace, wherein each group in the preset composition material The mass percentage range is: C: 3.2%-3.6%, Si: 1.4-1.8%, Mn: 0.1-0.5%, P: ≤0.015%, S: ≤0.015%, Cr: ≤0.6%, Cu: ≤0.8 %, Ni≤1.0%, the total amount of other alloy elements: ≤1.0% and the balance is Fe, the sum of the mass percentages of...

Embodiment 1

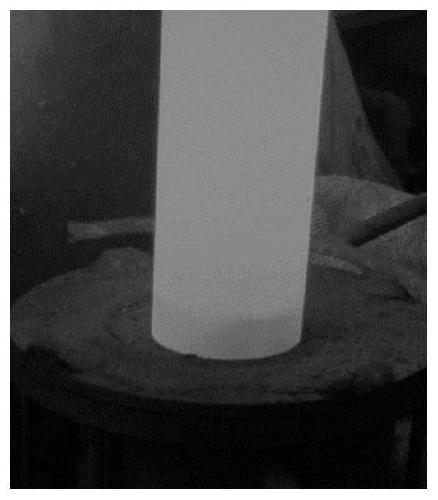

[0057] Objective: To draw a ductile iron hollow profile with an outer diameter of 200mm and a wall thickness of 20mm, and prepare it into eutectic graphite steel with a hardness ≥ HRC45.

[0058] Casting materials (60% Q14 # Bread iron, 20% low-carbon steel scraps, 20% nodular iron return material) are melted into molten iron in an intermediate frequency induction furnace, and adjusted to the mass percentages of the following components: C: 3.30% ± 0.05%, Si: 1.6 ± 0.05 %, Mn ≤ 0.2%, P: ≤ 0.015%, S: ≤ 0.015%, Cu: 0.6%, Ni ≤ 0.6%, Cr: ≤ 0.3% and the balance Fe, the sum of the mass percentages of each component is 100%.

[0059] After the molten iron reaches 1530°C, set aside for 20 minutes, pour 300Kg into the hanging bag, put 4.5Kg of cerium rare earth magnesium nodulizer (accounting for 1.5% of the weight of the molten iron) in advance in the bottom pit of the hanging bag, and cover it with nodular iron filings; wait for nodularization After the reaction is completed, add 75...

Embodiment 2

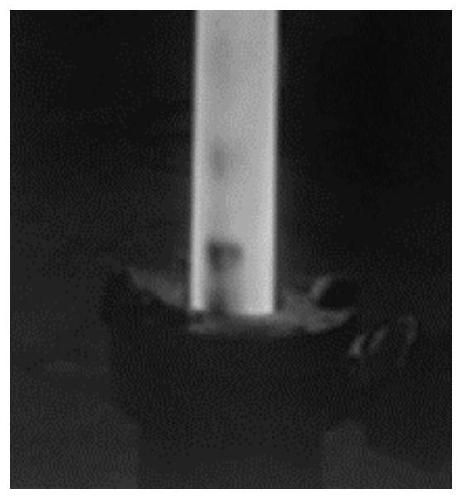

[0076] Objective: To draw a ductile iron hollow profile with an outer diameter of 100mm and a wall thickness of 10mm, and prepare it into eutectic graphite steel with a hardness ≥ HRC32.

[0077] For brief description, for the parts not mentioned in this embodiment, reference may be made to Embodiment 1.

[0078] Casting materials (60% Q14 # Bread iron, 20% low-carbon steel scraps, 20% nodular iron return charge) are melted into molten iron in an intermediate frequency induction furnace, and adjusted to the mass percentages of the following components: C: 3.45% ± 0.05%, Si: 1.5 ± 0.05 %, Mn≤0.2%, P: ≤0.015%, S: ≤0.015%, Cu≤0.6%, Ni≤0.8%, Cr: ≤0.2% and the balance is Fe, the sum of the mass percentages of each component is 100% .

[0079] It should be noted that the final silicon content of the molten iron after inoculation and spheroidization treatment is 2.80%±0.05%, and the residual magnesium content is 0.035%-0.045%. After inoculation and spheroidization, the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com