A kind of preparation method of flake-shaped nano-nickel oxide

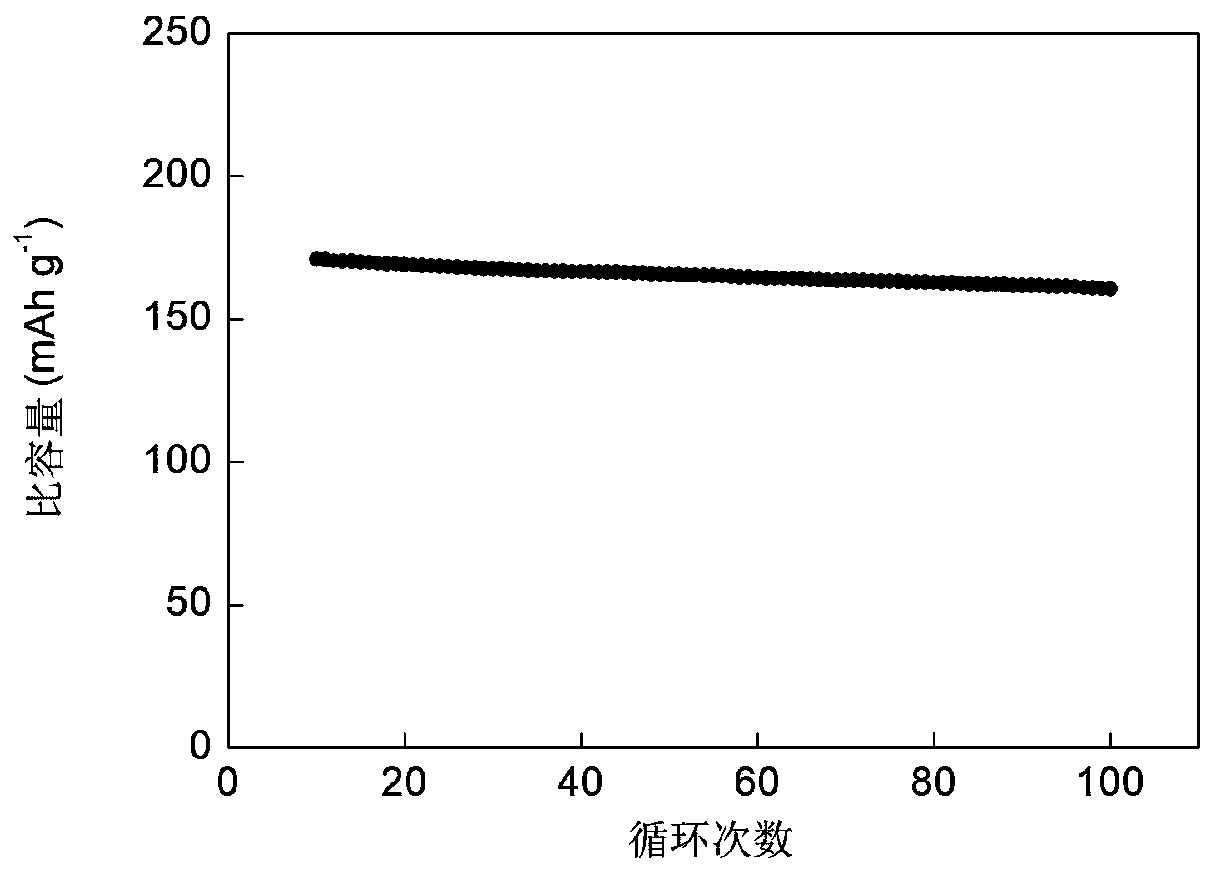

A nano-nickel oxide, flake technology, applied in the field of electrochemical material preparation, can solve problems such as difficulty in meeting requirements, and achieve the effect of improving electrochemical performance and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing flower flake nano-nickel oxide, comprising the following steps:

[0024] The nickel matrix is electrolyzed in a chloride salt electrolyte to obtain a precursor;

[0025] The precursor is subjected to heat treatment to obtain flake-shaped nano-nickel oxide.

[0026] In the invention, the nickel matrix is electrolyzed in a chloride salt electrolyte to obtain a precursor. In the present invention, the nickel matrix preferably includes flat nickel or porous nickel, and the purity of the flat nickel or porous nickel is preferably above 99%. The present invention has no special requirements on the source of the flat nickel or porous nickel, and commercially available products known to those skilled in the art as working electrodes can be used.

[0027] In the present invention, in the chloride salt electrolyte, the concentration of chloride ions is preferably 15-100 g / L, more preferably 18-90 g / L, and even more preferably 20...

Embodiment 1

[0036] First, clean the pure nickel plate with distilled water to remove dust and sodium hydroxide solution, and then wash it with ionized water and ethanol to obtain a clean nickel surface; secondly, prepare NaCl electrolyte, Cl - Concentration is 35g / L; Then, the nickel plate that cleans up is immersed in electrolyte as working electrode; Utilize electrochemical anode constant current technology to carry out electrolysis (anode current is: 10mA / cm 2 ). As the electrolysis proceeds, green nickel hydroxide precipitates can be obtained in the solution. After the precipitate is washed and dried, it is placed in a muffle furnace for heat treatment at 250° C. for 10 hours to obtain a flake-shaped nano-nickel oxide product.

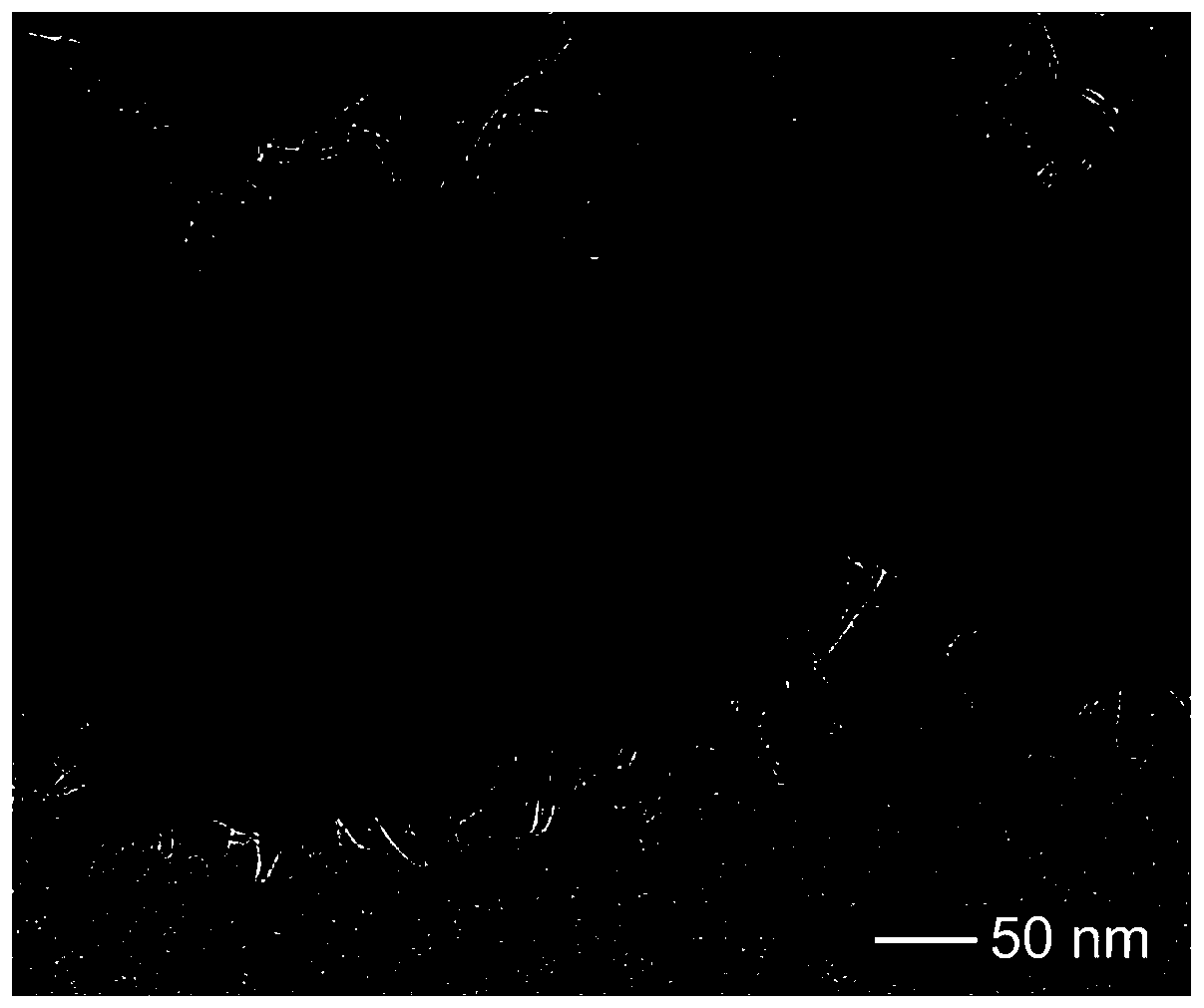

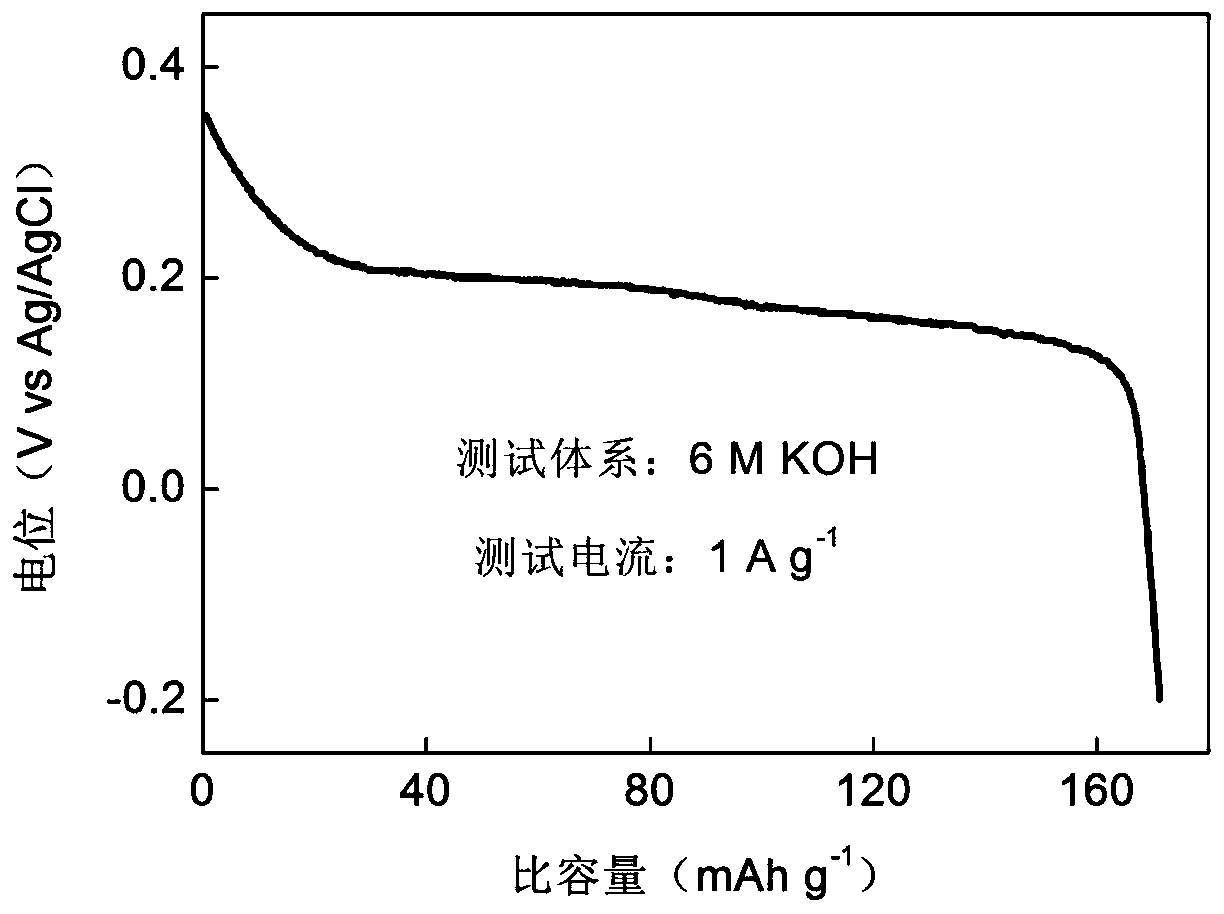

[0037] Utilize transmission electron microscope to characterize the morphology of embodiment 1 gained product, the result is as follows figure 1 shown. Depend on figure 1 It can be seen that the product obtained in Example 1 is a flake-like nano-nickel oxi...

Embodiment 2

[0040] First, the porous nickel was cleaned with distilled water to remove dust and concentrated alkali to remove oil, and then cleaned with ionized water and ethanol to obtain a clean nickel surface; secondly, NaCl+KCl electrolyte was prepared with a mass concentration ratio of 50%:50%, Cl - The total concentration is 15g / L; then, immerse the cleaned nickel plate as the working electrode in the electrolyte; utilize the electrochemical anode constant voltage technique to carry out electrolysis (by regulating the voltage so that the average value of the current is: 5mA / cm 2 ). As the electrolysis proceeds, green nickel hydroxide precipitates can be obtained in the solution. After the precipitate is washed and dried, it is placed in a muffle furnace for heat treatment at 450° C. for 1 hour to obtain a flake-shaped nano-nickel oxide product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com