Preparation method of SnO2/graphene lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., to achieve the effect of improving electrochemical performance, excellent cycle performance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

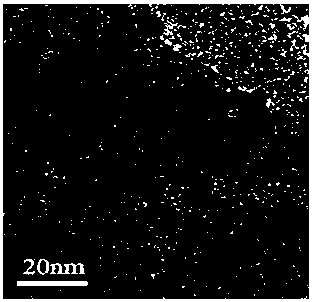

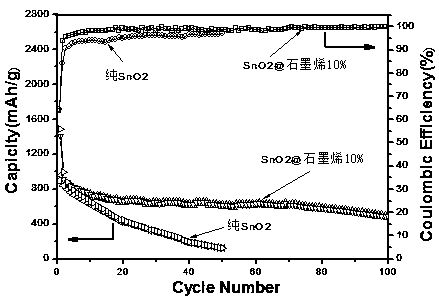

Image

Examples

Embodiment 1~3

[0029] A kind of SnO 2 / Graphene lithium ion battery anode material and preparation method thereof, including the following steps:

[0030] Step (1) Preparation of graphene oxide (or graphene) colloid

[0031] The classical Hummers method prepares graphene oxide colloid: will contain 23mL concentrated H 2 SO 4 The three-necked flask is fixed in an ice water bath (below 4℃), weigh 1g of natural flake graphite and add it to the flask, stir for 10min, then add 0.5g NaNO in batches 3 And 3gKMnO 4 , Keep stirring for 2h. After the low temperature oxidation is over, the temperature is raised to 35-40°C for 30 minutes of medium temperature oxidation. After the medium temperature oxidation is completed, 46 mL of deionized water is added, and the temperature is raised to 98°C for 30 minutes of high temperature oxidation. After the high temperature oxidation is over, add 140mL of deionized water and 5mL of H 2 O 2 (30 vol%) The reaction was terminated, filtered while hot, and the product was...

Embodiment 4~7

[0039] A kind of SnO 2 / Graphene lithium ion battery anode material and preparation method thereof, including the following steps:

[0040] Step (1) Preparation of graphene oxide colloid: the classical Hummers method is used to prepare graphene oxide colloid;

[0041] Step (2) Preparation of graphene oxide / Sn(OH) 4 Precursor: Measure different amounts of graphene colloids, add them to 50mL of deionized water, disperse for 60min by high-power ultrasound (ultrasonic power greater than 300W), and then add 4.7g of SnCl to the dispersion 4 ·5H 2 O, keep stirring to dissolve, slowly add 3.4gCO(NH 2 ) 2 , The temperature was raised to 90℃, and the reaction was stirred for 4h to obtain graphene oxide / Sn(OH) 4 The mixed solution is then filtered by suction, washed repeatedly until there is no chloride ion, and dried in vacuum to obtain graphene oxide / Sn(OH) 4 Solid powder

[0042] Step (3) High temperature synthesis of SnO 2 / Graphene lithium ion battery anode material: under argon atmospher...

Embodiment 8~12

[0047] A kind of SnO 2 / Graphene lithium ion battery anode material and preparation method thereof, including the following steps:

[0048] Step (1) Preparation of graphene oxide colloid: the classical Hummers method is used to prepare graphene oxide colloid;

[0049] Step (2) Preparation of graphene oxide / Sn(OH) 4 Precursor: Measure 20mL of graphene colloid, add it to 50mL of deionized water, disperse for 90min by high-power ultrasound (ultrasonic power is greater than 300W), then add different amounts of tin salt to the dispersion, continue to stir to dissolve, until the dissolution is complete Then slowly add an appropriate amount of precipitant, start to heat up to 90°C, stir and react for 4h to obtain graphene oxide / Sn(OH) 4 The mixed solution is then filtered by suction, washed repeatedly until there is no chloride ion, and dried in vacuum to obtain graphene oxide / Sn(OH) 4 Solid powder

[0050] Step (3) High temperature synthesis of SnO 2 / Graphene lithium ion battery anode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com