Lithium iron phosphate-coated lithium nickel-cobalt manganate and preparation method thereof

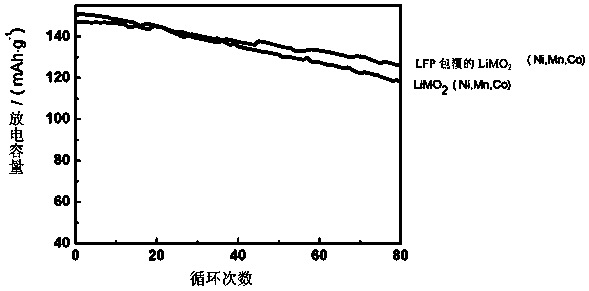

A technology of nickel-cobalt lithium manganese oxide and lithium iron phosphate, which is applied in the field of lithium-ion secondary battery cathode materials and its preparation, can solve problems such as poor cycle performance stability, achieve good safety and cycle performance, reduce contact, and complete crystal form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the first aspect of the present invention, the preparation method of the lithium iron phosphate-coated nickel-cobalt-manganese oxide comprises: under solvothermal reaction conditions, combining nickel-cobalt-manganese oxide with lithium source, iron source and phosphorus source The mixture of the lithium iron phosphate precursor mixed solution is heat-treated, the product obtained after the heat treatment is subjected to solid-liquid separation, and the obtained solid phase is dried. In the lithium iron phosphate precursor mixed solution containing lithium source, iron source and phosphorus source The solvent is an organic solvent.

[0027] According to the present invention, the organic solvent can effectively dissolve the lithium source, the iron source and the phosphorus source to form a uniform solution. Preferably, the organic solvent is selected from ethylene glycol, glycerol, diethylene glycol, triethylene glycol, One or more of tetraethylene glycol ...

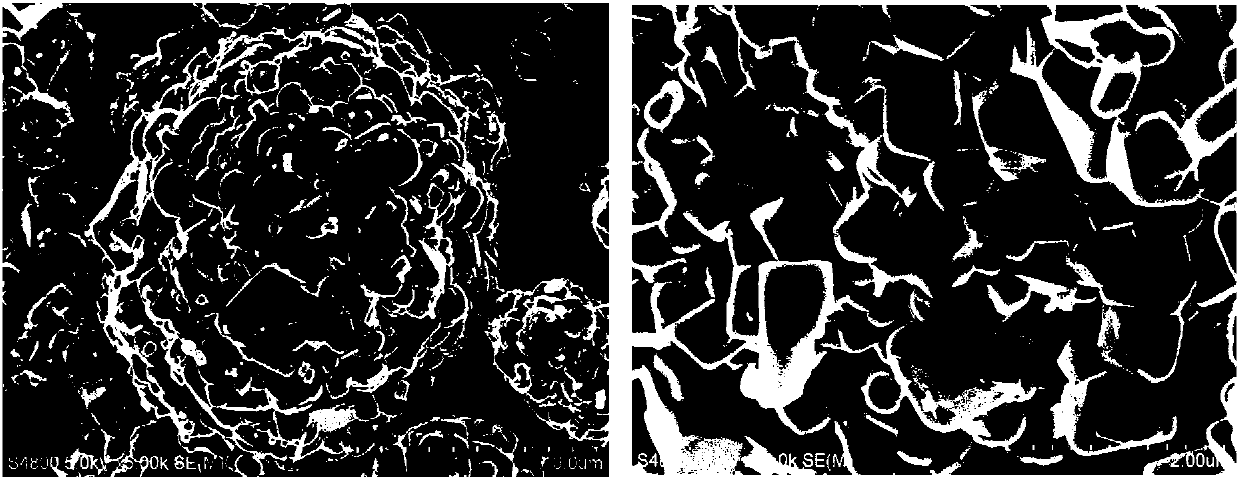

Embodiment 1

[0056] This example is used to illustrate the preparation of nickel cobalt lithium manganese oxide material coated with lithium iron phosphate.

[0057] Mixing of raw materials: Weigh LiOH·H 2 O, Fe(CH 3 COO) 2 4H 2 O each dissolved in 20ml of glycerol, the H3 PO 4 (mass fraction 85%) is added dropwise in the LiOH solution, forms the second solution, and Fe(CH 3 COO) 2 The solution is slowly added dropwise into the second solution to obtain a lithium iron phosphate precursor mixed solution containing a lithium source, a phosphorus source and an iron source. Wherein, the concentration of the iron source in the lithium iron phosphate precursor mixed solution is 0.05mol / L, and the molar ratio of lithium, iron, and phosphorus is 3:1:1.

[0058] Solvothermal method and post-treatment: add 3.88g of NCM622 ternary material to the lithium iron phosphate precursor mixture containing lithium source, phosphorus source and iron source obtained above, continue stirring for 5min, and ...

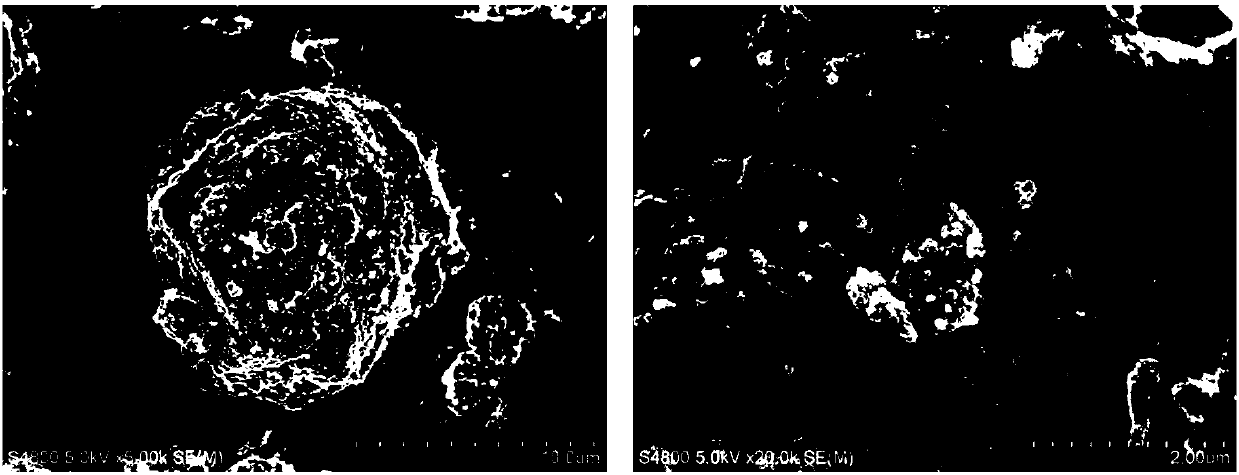

Embodiment 2

[0063] This example is used to illustrate the preparation of nickel cobalt lithium manganese oxide material coated with lithium iron phosphate.

[0064] Mixing of raw materials: Weigh LiOH·H 2 O, FeSO 4 ·7H 2 O each dissolved in 20ml of ethylene glycol, the H 3 PO 4 Added dropwise to FeSO 4 ·7H 2 In the O solution, the first solution was formed, and LiOH·H 2 The O solution is slowly added dropwise into the first solution to obtain a lithium iron phosphate precursor mixed solution containing a lithium source, a phosphorus source and an iron source. Wherein, the concentration of the iron source in the lithium iron phosphate precursor mixture is 0.1 mol / L, and the molar ratio of lithium, iron, and phosphorus is 2.7:1:1.

[0065] Solvothermal reaction and post-treatment: Add 3.88g of NCM622 ternary material to the lithium iron phosphate precursor mixture containing lithium source, phosphorus source and iron source obtained above, continue stirring for 5min, and finally tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com