Metal element-doped lithium iron phosphate-coated lithium nickel-cobalt manganate and preparation method thereof

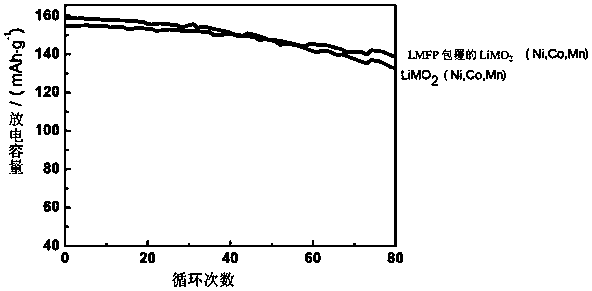

A technology of nickel cobalt lithium manganate and lithium iron phosphate, applied in the field of lithium ion secondary battery cathode material and its preparation, can solve problems such as poor cycle performance stability, achieve stable voltage platform, controllable size, and alleviate specific energy decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to the first aspect of the present invention, the preparation method of nickel-cobalt lithium manganese oxide coated with lithium iron phosphate doped with metal elements comprises:

[0028] Under solvothermal reaction conditions, the mixture of nickel-cobalt lithium manganese oxide and lithium iron phosphate precursor mixed solution doped with M element containing lithium source, doped metal M source, iron source and phosphorus source is heat-treated, and the heat-treated The obtained product is subjected to solid-liquid separation, and the obtained solid phase is dried, and the solvent in the M element-doped lithium iron phosphate precursor mixed solution containing lithium source, doped metal M source, iron source and phosphorus source is organic solvent.

[0029] According to the present invention, the organic solvent can effectively dissolve the lithium source, the doping metal M source, the iron source and the phosphorus source to form a uniform solution...

Embodiment 1

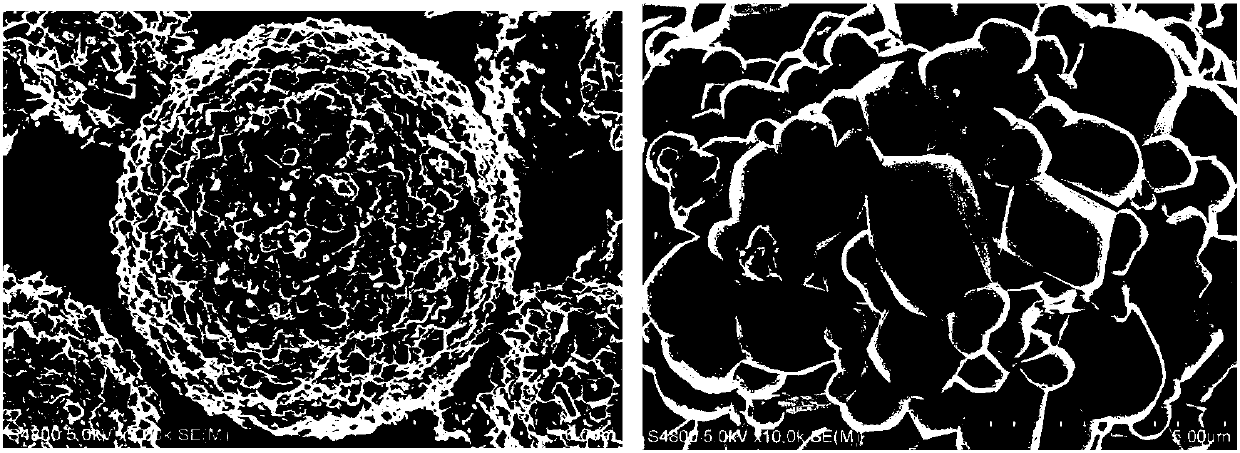

[0062] This example is used to illustrate the preparation of metal element doped lithium iron phosphate coated nickel cobalt lithium manganese oxide material.

[0063] Mixing of raw materials: Weigh the lithium source lithium hydroxide, the manganese source manganese chloride, the iron source ferrous sulfate, and the phosphorus source phosphoric acid respectively in proportion, and dissolve the lithium source, the manganese source and the iron source mixture in 20ml of ethylene glycol . Firstly, the mixed solution of ferrous sulfate, manganese chloride and phosphoric acid (mass fraction 85%) was mixed and stirred to form the first solution. Secondly, the lithium hydroxide solution was added dropwise to the first solution, and stirred for 30 minutes to obtain the M element-doped lithium iron phosphate precursor mixed solution containing lithium source, manganese source, phosphorus source and iron source. Among them, Mn concentration is 0.005mol / L, Fe concentration is 0.045mol / ...

Embodiment 2

[0069] This example is used to illustrate the preparation of metal element doped lithium iron phosphate coated nickel cobalt lithium manganese oxide material.

[0070] Mixing of raw materials: Weigh the lithium source lithium hydroxide, the manganese source manganese chloride, the iron source ferrous sulfate, and the phosphorus source phosphoric acid respectively in proportion, and dissolve the lithium source, the manganese source and the iron source mixture in 20ml of ethylene glycol . First, lithium hydroxide solution and phosphoric acid (mass fraction 85%) were mixed and stirred to form a second solution. Secondly, the mixed solution of ferrous sulfate and manganese chloride was added dropwise to the second solution, and stirred for 30 minutes to obtain an M element-doped lithium iron phosphate precursor mixed solution containing lithium source, manganese source, phosphorus source and iron source. Among them, the Mn concentration is 0.005 mol / L, the Fe concentration is 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com